Easy methods to cord a 1 cord alternator – Easy methods to cord a 1-wire alternator is a a very powerful ability for somebody running with automobile electric techniques. This information delves into the intricacies of single-wire alternator techniques, contrasting them with conventional multi-wire designs. We will discover the elements, wiring diagrams, troubleshooting, protection precautions, and upkeep schedules wanted to verify optimum efficiency and longevity.

Figuring out the diversities between unmarried and multi-wire alternators is paramount. Unmarried-wire techniques, whilst frequently more practical in design, call for a meticulous method to verify correct capability. This information will destroy down each and every step of the method, from preliminary setup to ongoing upkeep, equipping you with the data and self belief to take on this process effectively.

Advent to 1-Twine Alternators

One-wire alternator techniques are a specialised form of electric era machine utilized in more than a few programs, specifically in scenarios the place area constraints or cost-effectiveness are a very powerful components. They fluctuate considerably from the extra not unusual multi-wire alternator designs of their wiring configuration and inside elements. This distinction ends up in each benefits and downsides that want cautious attention when opting for a machine.-wire alternators use a unmarried cord to hold each the output voltage and the regulate alerts, in contrast to multi-wire techniques that use separate wires for each and every serve as.

This simplification of the wiring harness can result in important discounts in measurement and weight, making them appropriate for compact programs. Alternatively, the single-wire design additionally introduces complexities within the regulate and tracking of the alternator’s output.

Basic Variations Between 1-Twine and Multi-Twine Alternators

The core difference lies within the wiring scheme. Multi-wire alternators make use of a couple of wires, generally setting apart the facility output from regulate alerts. This separation permits impartial tracking and regulate, main to bigger flexibility and fault diagnostics. By contrast, 1-wire techniques combine each output voltage and regulate alerts onto a unmarried conductor. This integration simplifies the wiring however makes fault isolation and troubleshooting extra complicated.

Benefits of 1-Twine Alternator Programs, Easy methods to cord a 1 cord alternator

The benefits of 1-wire alternators are basically enthusiastic about cost-effectiveness and space-saving design options.

- Decreased Wiring Complexity: A unmarried cord considerably simplifies the wiring harness, decreasing the entire weight and area necessities for set up.

- Decrease Value: The lowered selection of wires and related elements generally translate to decrease production prices, making them horny for budget-conscious programs.

- Compact Design: The streamlined wiring configuration lets in for a extra compact alternator design, which is recommended in programs with restricted area.

Disadvantages of 1-Twine Alternator Programs

In spite of the benefits, 1-wire techniques have drawbacks that want cautious attention.

- Higher Fault Diagnostics Complexity: Troubleshooting problems turns into more difficult as a result of a unmarried cord carries each energy and regulate alerts, making it tougher to isolate the supply of any fault.

- Restricted Regulate Choices: The one-wire configuration may restrict the variability of regulate choices to be had in comparison to multi-wire techniques, impacting the precision of the alternator’s efficiency.

- Attainable for Sign Interference: A unmarried cord carries each output and regulate alerts, doubtlessly expanding susceptibility to sign interference from different elements within the machine.

Part Comparability

This desk illustrates the diversities in elements between 1-wire and multi-wire alternators.

Parts of a 1-Twine Alternator Machine

A 1-wire alternator machine, in contrast to conventional multi-wire setups, simplifies {the electrical} connections to the alternator. This streamlined method reduces the complexity of wiring and doubtlessly lowers production prices. Alternatively, figuring out the important elements and their interactions is very important for correct machine design and operation.

Crucial Parts

The core elements of a 1-wire alternator machine are designed for environment friendly energy era and supply. They paintings in live performance to transform mechanical power from the engine into electric power.

| Part Title | Serve as | Conventional Specs |

|---|---|---|

| Alternator | The guts of the machine, the alternator converts mechanical rotation into electric power. It homes the stator windings, rotor, diodes, and voltage regulator. | Output voltage: 12-14.4V; Output recent: Depending on engine RPM and cargo; Mounting kind: varies by means of utility |

| Rectifier Bridge | Converts the alternating recent (AC) generated by means of the alternator into direct recent (DC). That is a very powerful for charging the battery and powering the car’s electric machine. | Present capability: varies in line with alternator output; Voltage drop: generally minimum |

| Voltage Regulator | Maintains a strong output voltage from the alternator, without reference to adjustments in engine pace or load. It prevents overcharging the battery and protects {the electrical} machine. | Enter voltage vary: suits the alternator output; Output voltage: maintains a constant output voltage; Coverage options: over-voltage, over-current |

| Battery | Retail outlets the DC electric power generated by means of the alternator, offering a reserve energy supply for the car’s electric machine when the engine is off or at low RPM. | Capability: varies by means of car and alertness; Voltage: generally 12V; Amp-hour score: determines the quantity of rate saved |

| Wiring Harness (1-Twine) | The one-wire connection carries the mixed DC energy output from the alternator. This cord delivers {the electrical} power from the alternator to the battery. | Twine gauge: Dependent at the recent capability; Insulation: suitable for car environments; Connector kind: appropriate for the particular utility |

Part Interplay

The elements have interaction in a sequential approach to ship energy. The alternator, pushed by means of the engine’s crankshaft, generates AC energy. This AC energy is then rectified by means of the bridge rectifier into DC energy. The voltage regulator maintains a relentless voltage degree for the DC output, making sure the battery fees accurately and that different electric elements function inside the fitting voltage vary.

The 1-wire harness carries this DC power to the battery for garage.

The 1-wire machine considerably simplifies the wiring complexity in comparison to typical multi-wire techniques. This simplification ends up in charge financial savings in production and set up.

The battery, in flip, supplies the important energy to function the car’s electric elements when the engine isn’t operating. The program guarantees a competent energy supply for the car’s operation.

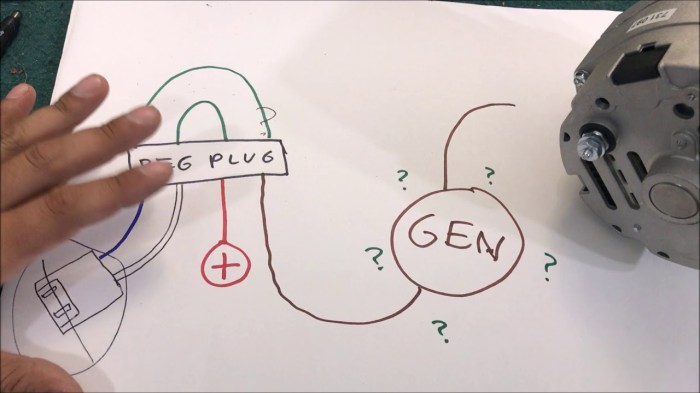

Wiring Diagrams and Procedures

A a very powerful side of putting in a 1-wire alternator machine is figuring out and accurately imposing the wiring diagrams. Correct wiring guarantees the machine purposes successfully and safely, keeping off attainable harm to the elements and the car’s electric machine. This phase main points more than a few wiring situations and set up procedures, emphasizing protection precautions.

Wiring Diagram Examples

Other configurations could also be required relying at the explicit car and alternator style. Those diagrams illustrate the connections for more than a few situations. Correctly figuring out and connecting the wires is paramount to the alternator’s operation and the car’s electric machine.

| State of affairs | Twine 1 Connection | Twine 2 Connection | Twine 3 Connection |

|---|---|---|---|

| State of affairs 1: Elementary Machine | Connect with the battery sure terminal. | Connect with the battery detrimental terminal. | Connect with the alternator’s box coil. |

| State of affairs 2: Machine with Exterior Regulator | Connect with the battery sure terminal. | Connect with the battery detrimental terminal. | Connect with the exterior regulator’s enter terminal. |

| State of affairs 3: Machine with Voltage Sensing | Connect with the battery sure terminal. | Connect with the battery detrimental terminal. | Connect with the voltage sensing circuit. |

Set up Procedures

The next steps element the method for putting in a 1-wire alternator, highlighting a very powerful protection measures. Cautious adherence to those procedures is significant for a a hit set up.

- Disconnect the Battery Terminals: Make sure that the car’s battery terminals are disconnected sooner than any electric paintings starts. This prevents brief circuits and electric shocks. This important step prevents unintentional electric shocks and guarantees the security of the installer.

- Establish the Wires: Sparsely read about the wires hooked up to the alternator and the car’s electric machine. Correct id of each and every cord is very important for a hit connection. Labeling wires with electric tape with a marker to correspond to the wiring diagram is very beneficial.

- Attach Twine 1: Attach the primary cord (generally the sure cord) to the sure terminal of the battery. Use the fitting measurement cord and make sure a safe connection to forestall any electric problems. Use suitable clamps or connectors to verify a safe and dependable connection.

- Attach Twine 2: Attach the second one cord (generally the detrimental cord) to the detrimental terminal of the battery. This completes the bottom connection. Once more, use suitable clamps and connectors for a safe connection.

- Attach Twine 3: Attach the 3rd cord (generally the sector coil cord) to the fitting terminal at the alternator. Test the right kind connection the use of the wiring diagram as a information. That is frequently essentially the most important step to verify the alternator purposes correctly.

- Reconnect Battery Terminals: Reconnect the battery terminals within the opposite order they had been disconnected. Make sure that the connections are safe and that no wires are touching each and every different. It is a ultimate important step, and making sure a good connection is necessary to forestall any electric issues.

- Check the Machine: Get started the car and observe the alternator’s output. Test the voltage output is throughout the specified vary for the car. This step guarantees the alternator is functioning as anticipated and the car’s electric machine is working correctly.

Protection Precautions

Adhering to those protection measures is significant for a a hit and secure set up.

- Put on Suitable Protection Equipment: Use protection glasses and gloves to offer protection to your self from attainable hazards. This is very important to offer protection to your eyes and fingers from conceivable harm right through set up.

- Paintings in a Smartly-Ventilated House: Paintings in a well-lit and well-ventilated space to forestall overheating and make sure correct airflow. This may occasionally lend a hand make sure that the installer is operating in a secure surroundings to forestall problems.

- Grounding Procedures: Make sure that correct grounding procedures are adopted to forestall brief circuits and electric shocks. It is a necessary step to verify the security of the installer and {the electrical} machine.

- Seek the advice of Wiring Diagrams: Sparsely find out about the wiring diagrams and practice the producer’s directions to steer clear of flawed connections. The usage of the wiring diagrams as a information is very important for keeping off errors.

- Test for Free Connections: Continuously take a look at for any unfastened connections or uncovered wires all over the set up procedure. Making sure safe connections is a important side of stopping problems.

Troubleshooting Commonplace Problems: How To Twine A 1 Twine Alternator

Troubleshooting a 1-wire alternator machine calls for a scientific method. Figuring out the foundation explanation for a malfunction is a very powerful for environment friendly maintenance and fighting additional harm. A radical figuring out of the machine’s elements and their interconnections is very important for correct analysis. Cautious remark of signs and methodical trying out procedures are key to keeping apart the inaccurate element.

Attainable Issues and Answers

Diagnosing problems in 1-wire alternator techniques comes to inspecting more than a few attainable issues. Cautious research of signs, mixed with suitable trying out procedures, lets in for correct id of the supply of the issue. This systematic method guarantees efficient maintenance and minimizes the danger of additional headaches.

| Drawback | Description | Answer |

|---|---|---|

| Alternator Output Low | The alternator isn’t generating sufficient voltage to correctly rate the battery. | Test the integrity of the diodes, brushes, and the stator windings. Test for unfastened connections within the wiring harness. Check up on the voltage regulator for correct serve as. If important, substitute the inaccurate element. Measure the output voltage on the battery terminals. |

| Alternator Output Prime | The alternator is generating over the top voltage, doubtlessly destructive electric elements. | Test the voltage regulator’s settings and calibration. Make sure that the voltage regulator is correctly fastened and secured. Test the wiring connections and continuity to verify correct serve as. If important, substitute the voltage regulator. |

| Alternator No longer Charging | The alternator isn’t supplying any energy to the battery. | Read about the diode bridge for any open circuits. Test the wiring connections for unfastened or corroded terminals. Test the fuse or circuit breaker is unbroken. Check the alternator’s output with a multimeter. Substitute the inaccurate element or wiring. |

| Battery No longer Charging | The battery isn’t receiving a rate from the alternator, regardless of the alternator’s output. | Check up on the wiring connections for unfastened or broken connections, specifically the bottom connection. Check the voltage regulator and make sure it is correctly regulating the charging recent. If conceivable, check the battery with a load tester. Substitute the battery if deemed inaccurate. |

| Machine Malfunctions with Prime Amperage Draw | The alternator struggles to care for output beneath excessive recent calls for. | Test for over the top parasitic quite a bit. Check up on the wiring for any problems that can reason resistance or warmth buildup. If important, improve the wiring gauge. Read about the alternator’s capability to take care of the present call for. |

Keeping apart the Inaccurate Part

Systematic trying out procedures are crucial for keeping apart the inaccurate element in a 1-wire alternator machine. This procedure frequently comes to a methodical way to establish the supply of the problem, minimizing the desire for in depth and doubtlessly pricey replacements. A step by step procedure is significant for accuracy and potency.

A scientific method is very important for figuring out the inaccurate element. This comes to checking the alternator’s output voltage, verifying the voltage regulator’s serve as, and examining the wiring for any attainable issues. Via methodically trying out each and every element, the supply of the problem can also be as it should be recognized.

As an example, if the alternator output is low, first take a look at the wiring connections. If the connections are sound, check the voltage regulator. If the voltage regulator is purposeful, continue to the diodes. This systematic procedure isolates the inaccurate element, making an allowance for centered maintenance and minimizing pointless replacements.

Protection Concerns

Operating with any electric machine, particularly high-voltage ones, calls for strict adherence to protection protocols. That is specifically important when coping with 1-wire alternator techniques, the place the opportunity of electric surprise and different hazards is provide. Prioritizing protection right through set up and upkeep minimizes dangers and guarantees a a hit result.Figuring out the possible hazards inherent in 1-wire alternator techniques is a very powerful for fighting injuries.

Those techniques, whilst providing benefits in simplicity, require cautious dealing with and a deep figuring out {of electrical} ideas. Thorough preparation and the usage of suitable protection apparatus are crucial.

Electric Surprise Hazards

Electric surprise is a vital fear in any electric paintings. 1-wire alternator techniques, because of their distinctive configuration, can pose upper dangers than typical techniques. The concentrated recent waft in one cord can result in extra critical surprise if correct precautions aren’t taken.

- At all times disconnect the facility supply sooner than any paintings at the alternator or wiring.

- Make sure that the facility supply is correctly grounded and secure towards surges.

- Use insulated gear and gloves rated for the voltage ranges concerned.

Correct Use of Protection Apparatus

Suitable protection apparatus is paramount for fighting accidents right through set up and upkeep. The usage of non-public protecting apparatus (PPE) is a important element of any secure electric paintings.

- Insulated gear and gloves are crucial for fighting electric touch.

- Protection glasses or goggles offer protection to the eyes from flying particles or sparks.

- Rubber-soled shoes supplies insulation towards electric surprise from touch with the bottom.

- Correct grounding tactics are important for fighting shocks and decreasing the danger of electrocution.

Attainable Hazards Related to 1-Twine Alternators

-wire alternator techniques, whilst simplified, introduce distinctive attainable hazards. Figuring out those dangers is a very powerful for correct set up and upkeep.

- Mistaken wiring can result in high-voltage spikes and electric arcing, inflicting burns or fireplace.

- Mistaken grounding can result in bad voltage drops or spikes, expanding the danger {of electrical} surprise.

- Overheating because of inadequate cooling can result in insulation failure and attainable fireplace hazards.

- A failure within the 1-wire machine can result in sudden high-voltage scenarios and severe dangers.

Protection Procedures and Warnings

Explicit protection procedures and warnings are crucial for running safely with 1-wire alternators. Adhering to those tips is necessary to forestall injuries and make sure secure operation.

- At all times seek the advice of the producer’s directions for explicit protection tips. Those paperwork Artikel important steps for secure operation and upkeep. They supply detailed procedures, warnings, and cautions.

- Make sure that all connections are safe and correctly insulated. Free connections are a significant supply {of electrical} issues and can result in shocks, burns, and fires. Correctly tightening connections and making sure insulation are a very powerful for protection.

- Continuously investigate cross-check the wiring and elements for indicators of wear or put on. Preemptive upkeep, together with visible inspections and element tests, can save you attainable problems and hazards.

- Paintings in a well-ventilated space to steer clear of the accumulation of fumes or gases. That is specifically essential for upkeep involving cleansing or changing elements.

Choice Configurations and Packages

One-wire alternator techniques, whilst providing simplicity, can also be tailored for more than a few programs past elementary charging. Other configurations and specialised setups cater to precise wishes and tool calls for, frequently involving changes to the usual wiring. Figuring out those diversifications is a very powerful for optimum machine efficiency and protection.

Diversifications in Wiring Configurations

Other programs require explicit changes to the elemental one-wire alternator machine. The elemental concept stays the similar, however the implementation can range significantly. Those changes may come with including diodes, resistors, or different elements to keep an eye on recent waft and voltage. This adaptability is without doubt one of the key benefits of one-wire techniques.

- Charging More than one A lot: For techniques requiring a couple of quite a bit (e.g., battery charging and accent energy), the one-wire alternator can also be configured with further circuits. This comes to the use of diodes to isolate the quite a bit and save you back-feeding, making sure that each and every load receives the important voltage. As an example, a small motor may well be hooked up to a separate circuit department to attenuate interference with battery charging.

- Integrating with Different Programs: One-wire alternators can also be built-in with different charging techniques, like sun panels. This mixture lets in for a hybrid charging method, offering redundancy and maximizing energy potency. As an example, a sun charging machine may prioritize charging the battery right through sunlight hours, whilst the alternator kicks in when solar energy is inadequate.

- Specialised Voltage Legislation: Some programs call for actual voltage legislation. Enforcing voltage regulators within the one-wire setup lets in for keeping up a strong output voltage without reference to load fluctuations. That is specifically essential in programs the place delicate digital apparatus is concerned, corresponding to in telecommunications techniques or specialised instrumentation.

Specialised Setups for Distinctive Wishes

The adaptability of one-wire alternator techniques lets in for specialised configurations adapted to precise calls for. Those configurations frequently contain cautious collection of elements and actual wiring to succeed in the required result.

- Far flung Charging Programs: One-wire alternators can also be a part of a far flung charging machine, offering energy to gadgets or batteries situated clear of the principle energy supply. This setup is a very powerful in programs the place bodily get entry to is proscribed, corresponding to in far flung tracking stations or off-grid houses.

- More than one Battery Programs: Some techniques make the most of a couple of batteries. The only-wire alternator can also be configured to rate those batteries concurrently, making sure a powerful energy provide. That is frequently observed in marine programs the place a couple of batteries supply backup energy.

- Auxiliary Energy Programs: The only-wire configuration can energy auxiliary apparatus like electrical winches, water pumps, or lights techniques. This comes in handy in development, agricultural, or marine contexts the place further energy is wanted for duties past elementary charging.

Explicit Use Instances

One-wire alternator techniques have more than a few programs the place simplicity and reliability are paramount. Those come with more than a few off-grid situations, far flung operations, and specialised programs requiring low upkeep.

- Off-Grid Energy Programs: In rural spaces or far flung places, a one-wire alternator generally is a necessary element of an off-grid energy machine, offering a competent charging resolution for batteries used to energy lighting fixtures, home equipment, and different must haves.

- Marine Packages: One-wire techniques are appropriate for marine environments because of their ruggedness and the opportunity of simplified wiring, particularly in far flung spaces of the boat.

- RV and Camper Programs: One-wire alternators are frequently built-in into RV and camper techniques because of their compact measurement and simplicity of set up. They supply a blank and environment friendly method to energy more than a few onboard techniques, from lights to home equipment.

Repairs and Repairs Time table

Correct upkeep of a one-wire alternator machine is a very powerful for making sure its longevity, optimum efficiency, and protection. Neglecting common inspections and maintenance can result in untimely failure, pricey maintenance, and attainable hazards. A well-maintained machine operates successfully, generating the desired electric output and minimizing the danger of breakdowns.Common upkeep duties, when carried out diligently, can considerably lengthen the lifespan of the alternator and its related elements.

This proactive method prevents sudden problems, decreasing downtime and making sure constant energy supply. The beneficial upkeep agenda and procedures detailed underneath supply a framework for efficient maintenance, enabling customers to care for the machine’s reliability.

Really useful Repairs Time table

Common inspection and upkeep duties are crucial for the dependable operation of a one-wire alternator machine. This proactive method is helping establish attainable issues early, fighting pricey maintenance and making sure constant efficiency. The next agenda Artikels the beneficial upkeep duties and their corresponding frequencies.

| Job | Frequency |

|---|---|

| Visible Inspection of Wiring Connections | Weekly |

| Test for Corrosion or Harm to Wiring | Per month |

| Test for correct tightening of all connections | Per month |

| Check up on for unfastened or broken elements (e.g., diodes, regulator) | Quarterly |

| Test output voltage and recent with a multimeter | Quarterly |

| Blank and lubricate shifting portions (if acceptable) | Yearly |

| Thorough inspection of all elements | Semi-annually |

| Substitute worn or broken elements | As wanted |

Significance of Common Inspections

Common inspections are important to figuring out attainable problems sooner than they escalate into primary issues. Early detection of corrosion, unfastened connections, or broken elements can save you malfunctions and save important restore prices. Recommended consideration to minor issues frequently interprets to really extensive charge financial savings and guarantees the machine continues to serve as reliably.

Regimen Repairs Duties

Those procedures describe the particular steps fascinated by each and every upkeep process. Following those tips will lend a hand care for the alternator’s optimum efficiency and lengthen its lifestyles.

- Visible Inspection of Wiring Connections: Sparsely read about all wiring connections for indicators of wear, corrosion, or looseness. Search for any proof of overheating or discoloration. Tighten unfastened connections as wanted.

- Checking for Corrosion or Harm to Wiring: Check up on the wiring harness for any indicators of corrosion, cuts, or abrasions. Substitute any broken or corroded sections to forestall brief circuits or electric problems.

- Checking Tightening of Connections: Test that each one connections are securely tightened. Make certain that terminals are firmly hooked up and unfastened from any indicators of loosening. Correct tightening prevents voltage drops and attainable sparking.

Ultimate Wrap-Up

In conclusion, wiring a 1-wire alternator, whilst apparently complicated, turns into manageable with a methodical method. Via sparsely finding out the elements, wiring diagrams, and troubleshooting tactics Artikeld on this information, you can be well-equipped to put in and care for a 1-wire alternator machine. Be mindful protection is paramount, and common upkeep will lengthen the lifetime of your alternator considerably.

FAQ

Q: What are the standard voltage and amperage outputs for a 1-wire alternator?

A: Specs range in line with the particular alternator style. Seek the advice of the producer’s documentation for actual main points.

Q: How do I establish the right kind wires for the 1-wire alternator in my car?

A: Discuss with the car’s electric schematic and the alternator’s wiring diagram for correct id.

Q: What are some not unusual reasons of a 1-wire alternator no longer charging?

A: Imaginable reasons come with a inaccurate regulator, unfastened connections, or a broken diode. A multimeter can lend a hand diagnose the issue.

Q: What’s the significance of grounding in a 1-wire alternator machine?

A: Correct grounding is a very powerful for fighting electric shorts and making sure the alternator purposes accurately. A deficient floor can result in charging problems and even harm to the machine.