Methods to prevent mikuni carb from operating lean? This information supplies a complete method to diagnosing and resolving lean operating problems in Mikuni carburetors. Figuring out the indicators, jetting, air leaks, gasoline supply, and upkeep is a very powerful for restoring optimum engine efficiency. Correctly addressing those parts guarantees a easy and environment friendly operating engine, a very powerful for any car or device depending on a Mikuni carb.

Figuring out the particular reason for a lean situation is step one. Signs like tough idling, hesitation, and deficient acceleration are continuously signs. Analyzing the carburetor visually and routinely for air leaks or incorrect jetting is important for pinpointing the issue.

Figuring out the Lean Situation

A Mikuni carburetor operating lean gifts a definite set of signs, simply distinguishable from different commonplace problems. Spotting those indicators is a very powerful for well timed prognosis and efficient troubleshooting, fighting additional harm to the engine. Right kind id lets in for focused changes to revive optimum efficiency.Lean operating, a situation the place inadequate gasoline mixes with the air getting into the engine, can manifest in more than a few tactics.

Distinguishing it from different carburetor issues like flooding or operating wealthy calls for cautious commentary of engine efficiency, exhaust traits, and visible inspection issues.

Signs of Lean Working

Lean operating is characterised by means of a noticeable drop in engine energy and function. The engine might sputter, hesitate, and even stall, particularly underneath load. The loss of enough gasoline may cause an erratic and asymmetric energy supply. A noticeably tough idle is a common symptom. The engine may really feel susceptible and underpowered, in particular when accelerating.Exhaust emissions supply additional clues.

Lean combustion continuously produces a noticeably “skinny” or “stinging” exhaust scent. The exhaust colour may additionally showcase extraordinary traits, starting from a faded blue to a just about white and even colorless look, not like the wealthy, darkish, and dense exhaust noticed in a appropriately running engine. That is because of incomplete combustion. Visible inspection of the exhaust gadget is necessary.

Visible Inspection Issues

Visible inspection of the engine and carburetor elements supplies treasured insights into attainable problems. Test for over the top warmth buildup across the carburetor and consumption manifold. Overheating in those spaces continuously issues to lean operating and deficient gasoline aggregate. Read about the spark plug for indications of lean operating. A lean situation continuously manifests as a faded, mild grey, and even white-colored spark plug.

The spark plug will even continuously showcase a characteristically “darker” look than a wealthy spark plug.

Distinguishing Lean Working from Different Problems

Lean operating differs from flooding, a situation the place over the top gasoline overwhelms the engine. Flooding manifests as an excessively rainy engine, continuously with white smoke. Working wealthy, alternatively, is characterised by means of a very dense fuel-air aggregate, resulting in black exhaust smoke. A wealthy engine will even normally run easily, although most likely with over the top gasoline intake.

Mechanical Inspection

Thorough mechanical inspection of the carburetor is very important. Take away the air clear out and visually check out the air clear out housing for any cracks, holes, or different indicators of air leaks. Check out the throttle frame and any vacuum traces for cracks or different harm that might result in air leaks. A leak within the gasoline line or supply gadget may cause lean operating.

Test that every one connections are safe and that no gasoline is leaking.

Doable Reasons of Lean Working

| Motive | Symptom | Doable Answer |

|---|---|---|

| Mistaken Jetting | Engine sputters, hesitates, or stalls; asymmetric energy supply; faded or colorless exhaust | Modify pilot jet, primary jet, and/or needle jet sizes |

| Air Leaks | Engine sputters, hesitates, or stalls; asymmetric energy supply; faded or colorless exhaust; engine overheating | Establish and seal any leaks in consumption gadget, vacuum traces, or gaskets |

| Misguided Gasoline Supply Machine | Engine sputters, hesitates, or stalls; asymmetric energy supply; faded or colorless exhaust; conceivable gasoline hunger | Test gasoline pump, gasoline traces, and gasoline clear out for correct serve as; be certain that proper gasoline stage |

Figuring out Jetting

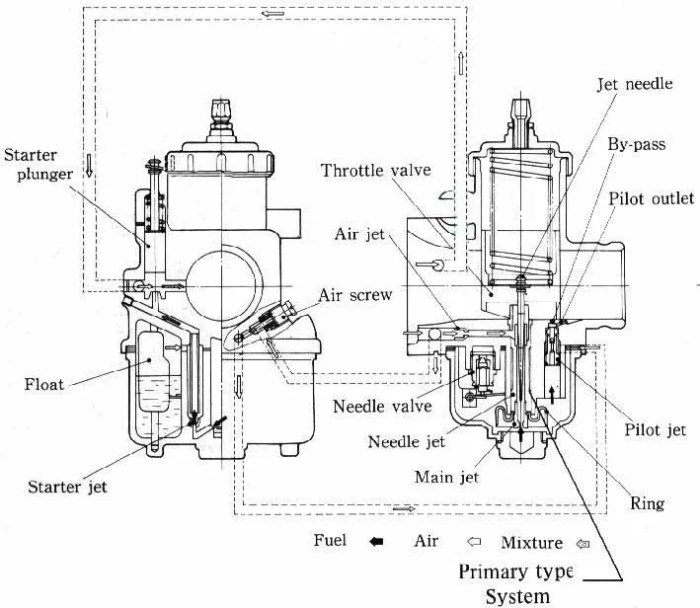

Mikuni carburetors, a very powerful elements in lots of small engines, exactly regulate the fuel-air aggregate for optimum efficiency. Figuring out the intricate dating between other jets is paramount to fine-tuning your engine’s gasoline supply. Right kind jetting guarantees environment friendly combustion, energy output, and lowered emissions.The Mikuni carburetor’s complicated jetting gadget performs an important position in handing over the right fuel-air aggregate for optimum engine efficiency.

Other jets regulate gasoline go with the flow at various engine speeds, enabling a easy transition from idle to excessive RPMs. As it should be deciding on jets is a very powerful for keeping up correct gasoline supply, fighting lean or wealthy stipulations, and making sure a responsive and strong engine.

Serve as of Mikuni Carburetor Jets

The Mikuni carburetor makes use of a sequence of jets to exactly meter gasoline go with the flow at other engine speeds. Every jet performs a particular position within the gasoline supply gadget. The principle jet, pilot jet, and needle jet, paintings in live performance to control gasoline supply throughout all of the engine pace differ.

Major Jet

The principle jet is the biggest jet within the gadget and basically controls gasoline supply at upper engine speeds. Visualize it as a number one valve for gasoline go with the flow all through acceleration and high-load operation. Its dimension immediately impacts the volume of gasoline to be had to the engine at those speeds. Higher primary jets permit extra gasoline go with the flow, whilst smaller primary jets limit it.

Pilot Jet

The pilot jet is a smaller jet, positioned close to the throttle valve, and regulates gasoline go with the flow at idle and occasional engine speeds. It is a very powerful for beginning and keeping up a solid idle. Its dimension determines the gasoline supply at low RPMs, impacting the engine’s talent to easily transition from idle to raised speeds.

Needle Jet

The needle jet, positioned inside the primary jet space, adjusts gasoline go with the flow in keeping with throttle place. Believe it as a variable valve, controlling gasoline go with the flow in percentage to throttle opening. This permits for an acceptable fuel-air aggregate because the engine’s load and pace build up.

Dating Between Jets

The principle jet, pilot jet, and needle jet paintings in tandem to verify a constant gasoline aggregate throughout all of the engine pace differ. The pilot jet manages low RPMs, whilst the primary jet handles upper RPMs. The needle jet adjusts gasoline supply dynamically because the throttle opens and closes, keeping up a constant aggregate all over the running differ.

Jet Measurement Comparability

Other jet sizes immediately affect the gasoline aggregate. Higher jet sizes permit extra gasoline to cross via, leading to a richer aggregate. Smaller jet sizes limit gasoline go with the flow, resulting in a leaner aggregate. An exact steadiness between jet sizes is very important for optimum engine efficiency.

Deciding on Right kind Jet Sizes

Opting for the right kind jet sizes is a very powerful for optimum engine efficiency in more than a few stipulations. Components equivalent to engine sort, altitude, and cargo affect the desired gasoline aggregate. Upper altitudes require leaner combinations because of thinner air, whilst heavier quite a bit necessitate richer combinations. Seek the advice of your engine’s specs or a competent guide for steering on deciding on suitable jet sizes.

Jetting Configurations and RPM Levels

| Jet Measurement | Engine RPM | Gasoline Combination |

|---|---|---|

| 170 Major, 38 Pilot, 45 Needle | Idle to 3000 RPM | Lean |

| 175 Major, 40 Pilot, 45 Needle | Idle to 4000 RPM | Quite Richer |

| 180 Major, 42 Pilot, 45 Needle | Idle to 5000 RPM | Wealthy |

This desk supplies a basic tenet for various jetting configurations. The correct jetting necessities might range in keeping with explicit engine fashions and prerequisites. At all times seek the advice of your engine’s guide for explicit suggestions.

Troubleshooting Air Leaks

Air leaks in a Mikuni carburetor can considerably affect its efficiency, resulting in a lean operating situation. Figuring out and sealing those leaks is a very powerful for reaching optimum fuel-air aggregate and engine energy. This phase will element commonplace places for air leaks, supply a methodical process for detection, and recommend efficient sealing ways.

Commonplace Air Leak Places

Air leaks can happen in more than a few spaces of a Mikuni carburetor setup. Figuring out attainable leak issues lets in for a centered inspection procedure.

- Throttle Frame Gaskets: Those gaskets seal the throttle frame to the carburetor frame. Cracks, tears, or incorrect seating of the gasket can create important air leaks. The gasket’s integrity is important for a constant air-fuel ratio.

- Throttle Shaft and Linkage: Any gaps or play within the throttle shaft or linkage gadget lets in for accidental air consumption. A free connection or a worn-out linkage part can disrupt the correct throttle operation.

- Carburetor Frame to Manifold Connections: The relationship between the carburetor and consumption manifold can leak if the mating surfaces are tough or improperly sealed. Right kind manifold gasket seating is very important for keeping up a constant air-fuel aggregate.

- Gasoline Inlet/Outlet Fittings: Free or broken connections at the gasoline inlet or outlet traces can permit for air to go into the gadget. Check out those spaces meticulously for any indicators of leakage.

- Vacuum Traces and Connections: Vacuum traces, if cracked or disconnected, can create leaks. Be sure all vacuum traces are securely hooked up and freed from cracks or harm. Those traces continuously result in vacuum-dependent elements like the ability valve.

- Carburetor Base or Housing: Leaks can happen across the carburetor base or housing. Test for any cracks, gaps, or indicators of decay on this space.

Figuring out Air Leaks

Finding air leaks may also be difficult however turns into more uncomplicated with a scientific manner.

- Visible Inspection: Moderately read about all visual connections and elements for any indicators of leaks. Search for indicators of moisture or oil round gaskets, fittings, and connections. Visible exam will have to additionally come with a verify for cracks or breaks within the subject matter.

- Leak Detection Spray: A leak detection spray can assist pinpoint air leaks. Follow the spray to suspected spaces and pay attention for a hissing sound or follow for bubbles forming across the leak web page. This system lets in for correct id of leaks.

- Engine Operation: With the engine operating, in moderation check out the connections and elements. Pay attention for hissing sounds or a transformation within the engine’s operation. A lean operating situation is usually a transparent indicator of air leaks.

- Manifold Power Check (Complicated): For a extra thorough inspection, a manifold force check may also be carried out. This check comes to measuring the force throughout the consumption manifold to spot any force drop. A drop in force continuously signifies a leak.

Sealing Air Leaks

Sealing air leaks calls for cautious number of fabrics and meticulous utility.

- Gasket Alternative: Broken gaskets will have to get replaced with new, top of the range gaskets. Be sure correct seating of the gaskets and use the fitting sealant if essential.

- Silicone Sealant: Silicone sealant is a flexible subject matter for sealing air leaks, particularly round difficult-to-reach spaces. Follow a skinny, even layer of silicone sealant to the affected spaces.

- Thread Seal Tape: Thread seal tape is appropriate for sealing threaded connections. Follow the tape in a spiral development to the threads sooner than connecting the elements.

- Prime-Temperature RTV Sealant: For top-temperature programs, high-temperature RTV sealant supplies an efficient answer. Follow a skinny layer of sealant to the joint and make allowance it to remedy in line with the producer’s directions.

Troubleshooting Procedures

To handle an air leak, a scientific manner is very important.

- Establish the Leak Location: The use of the strategies Artikeld above, pinpoint the precise location of the leak. This step is a very powerful for focused maintenance.

- Blank the Space: Completely blank the realm across the leak sooner than making use of any sealant. Taking away dust, particles, or outdated sealant will be certain that correct adhesion.

- Follow Sealant: Follow the fitting sealant to the leak web page, making sure a whole seal. Apply the producer’s directions for curing time.

- Reassemble: Moderately reassemble the elements, making sure correct alignment and tightness.

- Check: Get started the engine and carry out an intensive verify for any closing leaks. Pay attention for hissing sounds and follow the engine’s operation. If the issue persists, repeat the troubleshooting procedure.

Adjusting Gasoline Supply

High quality-tuning the gasoline supply gadget is a very powerful for reaching the optimum air-fuel aggregate in a Mikuni carburetor. Flawed go with the flow ranges may end up in a lean situation, leading to deficient engine efficiency, tough idling, and even engine stall. This phase main points the procedures for adjusting the go with the flow stage, gasoline pump, and gasoline traces, in conjunction with the affect of those changes at the total engine efficiency.

Flow Stage Adjustment Process

Exactly adjusting the go with the flow stage is important for keeping up the right kind gasoline provide. The go with the flow acts as a a very powerful part, making sure a constant gasoline stage throughout the carburetor bowl. A correctly adjusted go with the flow stage maintains the right kind gasoline provide for the engine’s wishes, fighting both flooding or hunger. Flawed go with the flow stage adjustment can considerably affect the engine’s efficiency, inflicting it to run lean or wealthy.

To regulate the go with the flow stage, first, find the go with the flow adjustment screw. That is normally a small, slotted screw at the underside of the go with the flow chamber. Use a small screwdriver to scrupulously regulate the screw, elevating or reducing the go with the flow. Slight changes can considerably have an effect on the gasoline supply. Over-tightening will have to be have shyed away from.

The go with the flow will have to be adjusted in order that the gasoline stage is slightly under the ground of the gasoline jet. This stage is important for making sure the right kind quantity of gasoline is brought to the engine.

Affect of Flow Peak on Gasoline Supply and Combination

The go with the flow top immediately influences the volume of gasoline drawn into the carburetor. The next go with the flow stage ends up in a better gasoline stage within the bowl, resulting in an over-rich aggregate. Conversely, a decrease go with the flow stage ends up in a decrease gasoline stage, leading to a lean aggregate. The connection is immediately proportional. A slight variation in go with the flow top can noticeably affect the engine’s efficiency.

A lean aggregate will purpose the engine to run scorching and doubtlessly harm elements. Conversely, a wealthy aggregate might purpose the engine to run poorly and bring over the top emissions.

Gasoline Pump or Similar Part Adjustment

Adjusting the gasoline pump, if acceptable, comes to analyzing the pump’s force and go with the flow charge. The gasoline pump’s number one serve as is to offer gasoline on the suitable force to the carburetor. If the pump is not functioning appropriately, the carburetor is not going to obtain the essential gasoline, resulting in a lean situation. Troubleshooting the gasoline pump calls for an intensive exam of its elements and connections.

If the gasoline pump is a mechanical pump, check out the pump’s diaphragm, valves, and is derived for any harm or put on. If the pump is electrical, be certain that the wiring is unbroken and the pump is receiving energy.

Gasoline Line and Similar Part Inspection

Analyzing the gasoline line and similar elements is very important for making sure a constant gasoline provide. Clogged gasoline traces, leaks, or kinks within the gasoline line can obstruct gasoline go with the flow, resulting in a lean situation. Moderately read about the gasoline line for any indicators of wear and tear, equivalent to cracks, splits, or kinks. Change any broken gasoline traces in an instant to keep away from gasoline leaks and make sure correct gasoline supply.

Additionally, verify for any leaks within the gasoline tank, gasoline clear out, or different similar elements.

Flow Stage Results on Engine Efficiency

| Flow Stage | Engine Reaction | Imaginable Problems |

|---|---|---|

| Too Prime | Engine runs wealthy, doubtlessly floods | Deficient acceleration, tough idling, over the top gasoline intake |

| Too Low | Engine runs lean, doubtlessly stalls | Deficient acceleration, tough idling, engine overheating, attainable harm to engine elements |

| Right kind | Engine runs easily, constant efficiency | No problems |

Repairs and Prevention: How To Prevent Mikuni Carb From Working Lean

Right kind upkeep is a very powerful for a Mikuni carburetor to serve as optimally and keep away from lean operating stipulations. Common cleansing and inspection save you sluggish deterioration, making sure constant gasoline supply and fighting efficiency problems. This phase main points crucial upkeep steps and preventative measures to handle your Mikuni carburetor’s well being.

Common Repairs Tick list

Common upkeep is essential to fighting lean operating stipulations. An intensive tick list guarantees you deal with crucial elements.

- Visually check out the carburetor frame for any indicators of wear and tear, cracks, or corrosion. Search for any bodily harm, like dents or scratches, that might affect airflow or gasoline supply.

- Check out the gasoline passages, jets, and go with the flow bowl for particles, dust, and polish buildup. Use a flashlight to meticulously verify for any blockages or extraordinary deposits which may be affecting the gasoline go with the flow.

- Read about the throttle linkage and cable for easy operation and correct adjustment. Be sure there aren’t any kinks, binding issues, or put on within the throttle meeting, as those may cause inconsistent throttle reaction.

- Test the air clear out for cleanliness and correct serve as. A clogged air clear out restricts airflow, forcing the carburetor to run lean. A blank clear out is very important for optimum efficiency.

- Test the go with the flow stage is proper. An wrong go with the flow stage impacts the volume of gasoline delivered, doubtlessly resulting in both flooding or lean operating. Use a precision gauge for correct measurements.

Cleansing the Carburetor

Cleansing the carburetor is a a very powerful upkeep job. Right kind cleansing guarantees optimum gasoline supply and stops lean operating.

- Disassemble the carburetor: Moderately take away the carburetor from the engine, and use suitable equipment and methods to disassemble it following the producer’s directions. Take footage or make detailed notes of the unique configuration for reassembly.

- Cleansing Brokers: Use a non-corrosive carburetor cleaner (equivalent to a twig cleaner). Steer clear of harsh chemical compounds that might harm the carburetor elements. For cussed deposits, a degreaser or a mix of heat water and delicate detergent may well be wanted.

- Cleansing Process: Completely blank each and every part with a cushy brush or compressed air, making sure no residue stays. Submerge the detachable portions within the cleansing agent, making sure all surfaces are coated. Use a cushy brush to scrub all crevices and jets. Be very cautious to not harm any small elements all through the method.

- Drying: Permit all portions to dry utterly sooner than reassembly. Use compressed air to take away any closing moisture. Be sure the portions are totally dry to forestall corrosion or malfunction.

- Reassembly: Reassemble the carburetor elements within the opposite order of disassembly, in moderation aligning all portions. Double-check all connections for correct seating.

Combating Lean Working Stipulations

Combating lean operating comes to a number of proactive measures. Constant upkeep is essential to fending off this factor.

- Right kind Air Clear out Repairs: Ceaselessly change or blank the air clear out to verify constant airflow. A clogged clear out can pressure the engine to run lean.

- Gasoline High quality: Use top of the range fuel with the advisable octane score in your engine. Deficient gasoline high quality can give a contribution to lean operating stipulations.

- Right kind Gasoline Supply Machine: Test and regulate the gasoline supply gadget elements to verify the correct gasoline aggregate is maintained. Be sure the gasoline traces are loose from blockages or leaks.

- Common Music-ups: Stay your engine tuned up. A well-maintained engine contributes to a constant gasoline aggregate and stops lean operating.

Garage Procedures

Right kind garage procedures for the carburetor save you harm and make sure its readiness to be used.

- Cleansing: Completely blank the carburetor sooner than garage, making sure all strains of gasoline and contaminants are got rid of.

- Drying: Permit the carburetor to dry utterly. This prevents corrosion and harm all through garage.

- Coverage: Retailer the carburetor in a blank, dry, and funky atmosphere. Protective it from excessive temperatures or moisture is very important.

- Sealing: Seal the carburetor in a protecting container to forestall mud and particles from getting into the carburetor.

Complicated Troubleshooting

Past fundamental jetting and air leaks, extra intricate problems may cause a Mikuni carburetor to run lean. Those issues continuously contain the interaction of more than one elements and require a scientific method to prognosis. Figuring out those complicated troubleshooting steps is a very powerful for reaching optimum efficiency and fighting attainable engine harm.

Vacuum Leaks

Vacuum leaks, continuously refined and hard to pinpoint, can considerably affect gasoline supply, leading to a lean operating situation. Those leaks can manifest as a hissing sound or a force drop throughout the consumption gadget. Pinpointing their location is essential to efficient restore.

- Visible Inspection: An intensive visible inspection of all hoses, clamps, and gaskets hooked up to the consumption manifold and carburetor is very important. Search for cracked, deteriorated, or free connections. Check out the gaskets between the carburetor and manifold for harm or misalignment. A telltale signal may well be a visual crack or a noticeable bulge in a rubber hose.

- Power Checking out: A force trying out approach comes to making use of managed force to the consumption manifold and tracking the force drop. This technique can pinpoint the precise location of a leak. A force gauge, hooked up to the consumption manifold, will display a gentle force drop if a leak is provide. The force drop charge can be utilized to estimate the severity of the leak.

A leak in a manifold gasket, as an example, would showcase a speedy force drop in comparison to a leak in a smaller hose.

- Smoke Checking out: Smoke trying out makes use of a smoke-generating answer offered into the consumption gadget. Any leaks will probably be visual as a plume of smoke escaping from the problematic space. This technique is efficacious for detecting hard-to-spot leaks, equivalent to the ones hid at the back of engine elements. This technique can be utilized for each exterior and inner leaks throughout the consumption gadget, which may another way be tough to spot.

Misguided Ignition Machine

A misguided ignition gadget too can result in a lean situation. Ignition timing, spark plug situation, and coil serve as immediately have an effect on the combustion procedure. A mistimed spark or a susceptible spark can impede correct gasoline combustion, resulting in a lean air-fuel aggregate.

- Ignition Timing: Flawed ignition timing can considerably have an effect on the potency of gasoline combustion. If the spark happens too early or too past due, the gasoline won’t burn utterly, leading to a lean situation. Right kind timing is a very powerful for whole combustion and environment friendly gasoline usage. Flawed timing may end up in an asymmetric energy supply or whole engine stall, and will have to be in moderation checked towards producer specs.

- Spark Plug Situation: A fouled or worn spark plug can impede the correct ignition of the air-fuel aggregate. Spark plugs will have to be inspected for fouling, over the top put on, or misalignment, and changed if essential. Carbon buildup at the spark plug can cut back its potency, resulting in inconsistent spark power and a lean situation. The colour of the spark plug can be utilized to diagnose combustion problems, which will then be correlated to a lean situation.

- Coil Serve as: A malfunctioning coil too can result in susceptible or inconsistent spark. The coil is chargeable for generating the excessive voltage required to create a spark around the spark plug hole. A misguided coil will ship a susceptible or inconsistent spark, resulting in a lean situation. Checking out the coil’s output voltage can assist pinpoint the issue.

Diagnostic Gear

A number of complicated diagnostic equipment can lend a hand in troubleshooting lean operating stipulations.

- Vacuum Gauge: A vacuum gauge is the most important software for detecting vacuum leaks. It measures the vacuum force throughout the consumption manifold. An important drop in vacuum force signifies a leak, serving to to find the issue space. Fluctuations in vacuum force, particularly at various engine speeds, can point out a leak this is more difficult to spot the use of visible strategies on my own.

- Oscilloscope: An oscilloscope can analyze electric indicators from the ignition gadget. This will assist diagnose problems like misfiring, susceptible sparks, and timing issues. An oscilloscope can show the waveforms generated by means of the ignition gadget, serving to establish discrepancies from the predicted indicators, which will then be correlated to a lean situation.

Troubleshooting Flowchart

A scientific method to troubleshooting is very important for diagnosing and resolving lean operating problems. The next flowchart supplies a structured manner.

| Step | Motion | End result |

|---|---|---|

| 1 | Visible Inspection (hoses, clamps, gaskets) | Leaks known? |

| 2 | Power Checking out (if visible inspection fails) | Leaks known? |

| 3 | Smoke Checking out (if force trying out fails) | Leaks known? |

| 4 | Ignition Timing Test | Right kind timing? |

| 5 | Spark Plug Inspection | Fouled or worn? |

| 6 | Coil Serve as Check | Misguided coil? |

| 7 | Modify Carburetor Settings (if no leaks or ignition problems) | Lean situation resolved? |

Engine Efficiency and Tuning

Optimizing engine efficiency with a Mikuni carburetor calls for figuring out the intricate dating between engine load and gasoline necessities. Various throttle positions, load stipulations, and RPMs all affect the carburetor’s talent to ship the right fuel-air aggregate for optimum combustion. This phase main points learn how to analyze and regulate engine settings to reach height efficiency underneath other running stipulations.Engine load considerably influences the gasoline call for.

Heavier quite a bit, equivalent to accelerating uphill or pulling a load, require extra gasoline for good enough energy output. Conversely, lighter quite a bit, equivalent to cruising at a relentless pace, necessitate a leaner aggregate to keep away from over the top gasoline intake and attainable engine harm.

Correlation Between Engine Load and Gasoline Necessities

Engine load is immediately proportional to the gasoline call for. A heavier load necessitates a richer gasoline aggregate to offer enough energy. A lighter load, alternatively, calls for a leaner aggregate for potency. This dating is a very powerful for correct carburetion and engine efficiency.

Adjusting Engine Settings for Various Load Stipulations

High quality-tuning the gasoline supply for various load stipulations is very important for optimum engine efficiency. This comes to adjusting the carburetor’s settings to check the converting gasoline necessities. That is perfect executed with a scientific manner.

- Idle Settings: At idle, the engine’s load is minimum. An exact idle aggregate guarantees easy operation with out stalling or over the top gasoline intake. Adjusting the idle aggregate screw lets in for this fine-tuning. Right kind idle pace and aggregate are crucial for constant engine operation.

- Mid-Vary Efficiency: Mid-range efficiency calls for a relatively richer aggregate than idle however leaner than complete throttle. Adjusting the primary jet and pilot jet aggregate is a very powerful on this space. Those changes permit for constant acceleration and gear supply around the mid-range RPMs.

- Complete Throttle: At complete throttle, the engine operates at most load. This calls for the richest gasoline aggregate conceivable. Cautious number of the primary jet dimension is important on this scenario. The mix will have to be wealthy sufficient to maintain the engine’s energy wishes however now not so wealthy as to create a chance of flooding or harm.

High quality-tuning the Gasoline Combination for Top Efficiency

Exact tuning of the gasoline aggregate is important for reaching height efficiency throughout all running stipulations. This comes to a scientific manner and cautious tracking.

- Preliminary Settings: Get started with the manufacturing unit advisable settings as a baseline. This gives a place to begin for changes.

- Load Checking out: Check the engine underneath various quite a bit, from idle to complete throttle, and notice any efficiency problems, equivalent to hesitation or sputtering. Those exams supply treasured knowledge for figuring out spaces desiring adjustment.

- Combination Changes: Steadily regulate the carburetor settings (idle aggregate screw, pilot jet, primary jet) in keeping with the weight trying out effects. This procedure is iterative and calls for persistence. Practice the engine’s reaction to each and every adjustment to resolve the optimum atmosphere.

Examples of Engine Tuning Tactics, Methods to prevent mikuni carb from operating lean

Other engine tuning ways, such because the “methodical manner” and the “modern adjustment” methodology, be offering various methods for fine-tuning the gasoline aggregate.

- Methodical Way: This comes to systematically adjusting each and every carburetor part (pilot jet, primary jet, idle aggregate screw) whilst tracking engine efficiency at other load stipulations. Every adjustment will have to be made in small increments and validated by means of trying out the engine’s reaction. This permits for actual tuning.

- Innovative Adjustment: This comes to progressively adjusting the primary jet dimension and pilot jet dimension whilst tracking the engine’s efficiency underneath various load stipulations. This technique makes a speciality of optimizing gasoline supply throughout all of the RPM differ. Changes are made in small increments and the engine is monitored intently.

Conclusive Ideas

Troubleshooting a lean-running Mikuni carburetor comes to a scientific manner. By means of figuring out jetting, figuring out and sealing air leaks, adjusting gasoline supply, and appearing common upkeep, you’ll optimize your engine’s efficiency. This information supplies a sensible framework for resolving lean operating problems. Take into account, correct upkeep is essential to fighting long term issues.

FAQ Information

What are the average signs of a Mikuni carburetor operating lean?

Commonplace signs come with tough idling, hesitation, deficient acceleration, and a noticeably wealthy or lean scent within the exhaust. The engine may additionally display indicators of overheating.

How continuously will have to I blank and check out my Mikuni carburetor?

Common cleansing and inspection, normally each 50-100 hours of operation, relying at the atmosphere and utilization, are crucial for optimum efficiency and to forestall lean operating problems.

What are some complicated troubleshooting ways for lean operating?

Complicated troubleshooting might contain checking for vacuum leaks, the use of diagnostic equipment to measure gasoline force, and analyzing the ignition gadget for problems.

What equipment are useful for figuring out air leaks in a Mikuni carburetor?

A leak down tester, smoke device, or perhaps a spray bottle of soapy water may also be useful equipment for locating air leaks.