Easy methods to forestall leaking at regulate valve and riser is a an important side of business repairs. Working out the foundation reasons, imposing fine troubleshooting methods, and adopting preventative repairs practices are very important for minimizing downtime and making sure operational protection. This complete information supplies an in depth research of the issue, providing insights into figuring out leaks, acting upkeep, and in the long run combating long term occurrences.

This information delves into the intricacies of regulate valve and riser leaks, protecting a spread of crucial facets from subject material variety to regulatory compliance. It explores quite a lot of attainable reasons, starting from inaccurate seals to wrong set up, and offers sensible troubleshooting ways for figuring out and keeping apart the supply of the leak. Moreover, the information supplies methods for restore, repairs, and preventative measures to make sure long-term operational reliability.

Figuring out the Reason for Leakage

Out of control leakage from regulate valves and risers may end up in important operational problems, impacting protection, potency, and environmental compliance. Working out the foundation reasons is paramount to fine troubleshooting and combating long term incidents. This calls for an intensive research of attainable elements, from inaccurate seals to wrong set up practices. A deep dive into the quite a lot of contributing elements will equip us with the information to diagnose and get to the bottom of those issues successfully.

Possible Reasons of Leakage

Leakage at regulate valves and risers can stem from a mess of things. Those come with problems with the valve’s elements, wrong set up procedures, or fluctuations in working stipulations.

- Misguided Seals: Keep an eye on valves depend closely on seals to forestall leakage. Broken or deteriorated seals are a not unusual supply of leakage. Other seal sorts showcase other failure modes. Examples come with worn O-rings, broken packing fabrics, or wrong seal alignment. Unsuitable set up, or repeated cycles of excessive strain, can boost up seal degradation.

- Worn Portions: Extended operation and publicity to harsh stipulations may end up in put on and tear on inside valve elements like stems, diaphragms, and valve our bodies. Put on continuously manifests as greater leakage. This may end up in pricey repairs and attainable protection hazards.

- Unsuitable Set up: Mistaken set up procedures may end up in misalignment, wrong seating, and different problems that give a contribution to leakage. Components like inadequate torque right through set up or mistaken valve positioning could cause leakage.

- Drive Fluctuations: Surprising or important strain adjustments can pressure seals and elements, doubtlessly inflicting leakage. Such fluctuations may also be led to by way of pump problems or sudden procedure calls for. Surprising strain spikes could cause current minor harm to turn into crucial, resulting in leakage.

- Subject material Degradation: The fabrics used within the building of regulate valves and risers can degrade over the years because of publicity to corrosive fluids, excessive temperatures, or different environmental elements. This degradation can weaken the fabric, doubtlessly resulting in leakage. As an example, stainless-steel uncovered to acidic environments might increase pitting corrosion.

- Float Charge Permutations: Adjustments within the move price can affect the stresses and forces performing at the valve elements. Prime move charges can exacerbate current put on, resulting in leakage. In a similar way, abrupt adjustments in move price can affect sealing elements.

Varieties of Seals and Failure Modes

Keep an eye on valves make the most of quite a lot of seal sorts, every with distinctive traits and susceptibility to failure.

- O-rings: O-rings are frequently utilized in regulate valves because of their simplicity and cost-effectiveness. On the other hand, they’re vulnerable to compression set and extrusion. Injury may end up from wrong set up, or over the top strain.

- Packing: Packing fabrics are utilized in quite a lot of valve designs to create a seal. Put on, degradation, and wrong tensioning are not unusual failure modes. The kind of packing subject material used is an important for the appliance, and the method working stipulations can have an effect on its lifespan.

- Diaphragms: Diaphragms are hired in some valve designs. Tears, punctures, and subject material degradation may end up in leakage. Unsuitable mounting or over the top strain may end up in those problems.

Working Stipulations and Their Affect

Working stipulations considerably affect the efficiency and longevity of regulate valves.

- Drive: Prime working pressures can pressure seals and elements, resulting in leakage. The connection between strain and leakage is usually exponential, with leakage expanding considerably as strain will increase.

- Temperature: Prime temperatures can boost up the degradation of seals and different fabrics, expanding the danger of leakage. Other fabrics have other tolerances for prime temperatures.

- Float Charge: Prime move charges can build up the shear and affect forces at the elements, doubtlessly inflicting leakage. Abrupt adjustments in move price will have a adverse impact on seals and different crucial portions.

Keep an eye on Valve Subject material Resistance to Leakage

The selection of subject material for regulate valves immediately affects their resistance to leakage.

| Subject material | Resistance to Leakage | Feedback |

|---|---|---|

| Carbon Metal | Reasonable | Prone to corrosion in explicit environments |

| Stainless Metal | Prime | Provides higher resistance to corrosion and put on |

| Alloy Metal | Very Prime | Very good resistance to corrosion and put on, however dearer |

| Hastelloy | Very good | Extremely proof against corrosion by way of quite a lot of chemical compounds |

Fabrics variety is important in combating leakage. Components just like the working surroundings, temperature, and strain want cautious attention.

Troubleshooting Tactics

The center-wrenching revel in of a leaking regulate valve or riser calls for a methodical and actual way. We will have to transfer past the preliminary surprise and concern of the unknown to systematically diagnose the supply of the leak and put in force swift, fine answers. A measured, step by step way is an important to combating additional harm and dear upkeep. Working out the supply and severity of the leak is the primary crucial step in making sure the protection and capability of all the machine.An intensive inspection isn’t just a job; it is a meticulous procedure challenging unwavering consideration to element.

This proactive way is an important for now not most effective containing the leak but in addition combating doubtlessly catastrophic penalties, akin to additional harm or unhealthy strain fluctuations. Each and every step, from visible checks to complex leak detection strategies, contributes to a complete figuring out of the issue.

Systematic Inspection Procedures

A methodical method to analyzing regulate valves and risers is essential. Start with a visible exam, meticulously scrutinizing each and every joint, becoming, and connection. Search for any indicators of corrosion, put on, or deformation. Pay specific consideration to spaces recognized to be prone to pressure or pressure. Subsequent, in moderation take a look at for any indicators of leakage, together with drips, puddles, or visual streams.

Record those observations meticulously. If imaginable, imagine the usage of specialised gear like borescopes for deeper exam of hard-to-reach spaces.

Assessing Leakage Severity

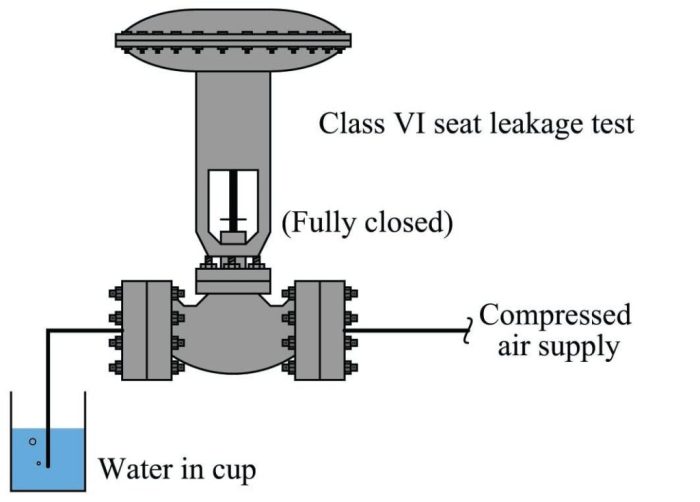

Correct overview of the leakage severity is very important for fine containment and service. Visible inspection supplies a initial overview, however extra definitive strategies are continuously required. Drive trying out comes to in moderation making use of managed strain to the machine whilst tracking for leaks. This permits for actual id of the leak’s location and severity. Specialised leak detection ways, akin to dye penetrants or acoustic emission, can pinpoint even minute leaks that could be neglected by way of visible inspection.

Each and every manner gives a novel point of view, enabling a complete figuring out of the issue’s scale.

Isolation of the Affected Phase

Swift isolation of the affected phase is paramount to containing the leakage and combating additional harm. This continuously comes to shutting down valves strategically to limit the move of fluids. Moderately imagine the prospective affect on different portions of the machine, and meticulously apply protection protocols to forestall accidental penalties. The function is to isolate the supply of the leak, taking into consideration managed restore with out jeopardizing the protection of staff or apparatus.

Protection will have to at all times be the highest precedence.

Vital Gear and Apparatus

| Class | Device/Apparatus | Description |

|---|---|---|

| Visible Inspection | Borescope, Flashlight, Magnifying Glass | Very important for analyzing hard-to-reach spaces and detecting delicate indicators of wear or leakage. |

| Drive Checking out | Drive Gauge, Drive Pump, Valves | Permits actual id of leak location and severity. |

| Leak Detection | Dye Penetrant Package, Acoustic Emission Detector | Pinpoints minute leaks neglected by way of visible inspection. |

| Isolation | Valves, Close-off mechanisms | A very powerful for holding the leak and combating additional harm. |

| Protection | Protection Glasses, Gloves, Non-public Protecting Apparatus | Very important for making sure the protection of staff right through the troubleshooting procedure. |

Restore and Upkeep Methods

A heart-wrenching revel in arises when a regulate valve or riser leaks. It is not only a mechanical downside; it is a attainable risk to potency, protection, and profitability. Addressing those leaks calls for a proactive way, transferring past merely solving the fast factor and delving into preventative repairs. The next methods be offering a roadmap to long-term luck, making sure your methods stay powerful and dependable.

Restore Choices for Leakage Issues

Other leakage eventualities necessitate adapted restore approaches. Working out the foundation purpose is an important to choosing the right answer. Listed here are a number of attainable restore choices:

- Seal Substitute: Broken seals are a not unusual wrongdoer. Changing worn-out seals with top quality, suitable replacements is continuously one of the best answer. This guarantees a decent, leak-free seal, combating additional harm and dear downtime. As an example, a inaccurate packing gland in a pneumatic regulate valve might want a whole substitute, making sure no air escapes in the course of the gland.

- Valve Changes: In some circumstances, minor changes to valve settings can get to the bottom of leaks. Calibration and fine-tuning of valve parameters can repair correct operation and do away with leaks. It is a cost-effective way if the issue is related to wrong valve positioning or strain settings. Actual changes to the valve stem and packing can repair its sealing functions.

- Part Restore: If a particular valve element is broken, such because the actuator or frame, restore or substitute is also essential. A broken actuator would possibly require specialised restore or substitute to make sure clean operation and save you long term leaks. Cautious exam of the affected phase is very important to resolve the level of the wear and tear and the most efficient restore technique.

- Riser Inspection and Restore: Leaking risers continuously level to corroded or broken sections. Thorough inspection of the riser, together with visible tests and strain trying out, is important to pinpoint the precise location of the wear and tear. Restore choices come with welding, patching, or changing corroded sections, making sure the integrity of the riser is restored. As an example, a crack in a riser pipe might necessitate welding to forestall additional leaks and attainable protection hazards.

Best possible Practices for Keeping up Keep an eye on Valves and Risers

Proactive repairs is paramount to combating leaks. Imposing a complete repairs time table, together with common inspections and preventative measures, considerably reduces the possibility of long term issues. It’s an funding in protection, potency, and long-term charge financial savings.

- Common Inspections: Visible inspections of valves and risers, coupled with periodic strain trying out, are very important to hit upon attainable problems early. This permits for well timed intervention, combating small issues from escalating into main leaks and dear upkeep. Common tests for corrosion, put on, and misalignment are essential in combating long term problems.

- Correct Lubrication: Keeping up correct lubrication of transferring portions, like valve stems, reduces friction and put on, extending the lifespan of the elements. Constant lubrication minimizes the danger of leaks because of mechanical put on and tear. This proactive way minimizes the will for emergency upkeep.

- Cleansing and Flushing: Common cleansing and flushing of the machine can take away particles and contaminants that may give a contribution to corrosion and leakage. That is particularly an important in harsh environments the place contaminants are prevalent. This an important step is an funding within the integrity of the machine.

- Documentation and Information: Keeping up detailed information of repairs actions, together with dates, procedures, and findings, is important for long term troubleshooting and making plans. This complete documentation guarantees that essential repairs is carried out and that any problems are promptly recognized and resolved.

Significance of Common Upkeep Schedules

Common repairs schedules are essential for minimizing leakage frequency and making sure the longevity of your regulate valves and risers. Constant repairs reduces sudden downtime and forestalls important monetary losses related to pricey upkeep.

“Proactive repairs is considerably cheaper than reactive repairs, the place problems are addressed most effective after they’ve escalated.”

Upkeep Procedures for More than a few Valve Varieties

A adapted repairs way is very important for various valve sorts. This desk Artikels the particular procedures for quite a lot of regulate valve sorts:

| Valve Sort | Inspection Procedures | Upkeep Procedures |

|---|---|---|

| Pneumatic Valves | Test for leaks in pneumatic strains, check out actuators for harm | Lubricate actuators, substitute seals if essential |

| Electrical Valves | Investigate cross-check wiring, take a look at motor operation | Blank contacts, lubricate transferring portions |

| Diaphragm Valves | Investigate cross-check diaphragm for harm, take a look at seals | Substitute broken diaphragms, be certain correct seating |

| Globe Valves | Test for leaks within the frame, check out stem for put on | Substitute worn portions, lubricate stem |

Fighting Long run Leaks

A continuing concern hangs over each and every operation, the threat of leaks. However prevention is not only about preventing the drips; it is about construction a machine the place leaks are anomalies, now not the norm. This an important step comes to a shift in point of view, transferring from reactive fixes to proactive design and upkeep. Via figuring out the foundation reasons and using sensible methods, we will forge a long term the place leaks are minimized, operations run easily, and everybody can breathe a collective sigh of reduction.

Design Concerns for Keep an eye on Valves and Risers, Easy methods to forestall leaking at regulate valve and riser

The design of regulate valves and risers immediately affects their susceptibility to leaks. Cautious attention of fabrics, tolerances, and strain scores is paramount. Using top quality, corrosion-resistant fabrics within the valve our bodies and riser piping is an important to resist the trials of operation. Precision in production and meeting reduces pressure issues, thus minimizing the danger of fatigue-induced cracking, a common wrongdoer in long-term leaks.

Thorough pressure research right through the design segment can assist determine and mitigate attainable vulnerable issues.

Significance of Correct Set up Procedures

Set up mistakes are a common supply of leaks, a silent risk lurking inside reputedly highest methods. Correct set up procedures, meticulously adopted, are essential for a leak-free operation. A misaligned valve, improperly tightened connections, or insufficient improve for the riser can all result in leaks that escalate over the years. Coaching staff on correct set up ways, the usage of the right kind gear, and adhering to established protocols are very important safeguards.

Using leak detection apparatus right through set up can catch problems early, saving time and combating main issues down the road. Moreover, rigorous high quality tests and common inspections during the set up procedure will have to be enforced to take care of excessive requirements.

Preventative Upkeep Methods

Proactive repairs is the cornerstone of leak prevention. Common inspections, well timed repairs tests, and diligent tracking of crucial elements can considerably cut back the possibility of long term incidents. This comprises checking for corrosion, verifying correct valve operation, and tracking strain fluctuations within the riser machine. The use of specialised gear and kit for leak detection can determine attainable problems early on.

Common lubrication and changes of transferring portions in regulate valves can considerably prolong their lifespan and save you untimely put on, a not unusual reason behind leakage.

Keep an eye on Valve Designs and Leakage Prevention Options

| Valve Design | Leakage Prevention Options | Instance Utility |

|---|---|---|

| Ball Valve | Easy design, continuously with double seals and top quality sealing fabrics; readily to be had for quite a lot of sizes and pressures. | Normal goal regulate programs |

| Globe Valve | Actual regulate over move charges; quite a lot of seat designs for various fluid viscosities and pressures. | Packages requiring actual move legislation |

| Butterfly Valve | Compact design, appropriate for high-flow programs; continuously used with resilient seals. | Massive-diameter pipelines, high-flow regulate |

| Diaphragm Valve | Seals with resilient diaphragms, excellent for corrosive fluids and programs requiring low repairs; usually utilized in chemical processes. | Chemical processing, corrosive liquids |

Each and every design has distinctive benefits and downsides in combating leakage, so your best option is determined by the particular software. Working out those options is essential to choosing the fitting valve for a given procedure and minimizing the danger of leaks.

Case Research and Examples

A continuing combat towards leaks, whether or not in regulate valves or risers, continuously exams the resilience of engineering groups. Those leaks are not simply inconvenient; they constitute a cascade of attainable issues, from manufacturing downtime and dear upkeep to protection hazards and environmental harm. Working out previous struggles and triumphs in mitigating those problems is an important to creating proactive and fine methods for the long run.

Let’s delve into some real-world eventualities.The disappointment of coping with a continual leak, the hours spent on diagnostics, and the relaxation of after all discovering an answer are all a part of the human revel in in engineering. Those case research remove darkness from the various demanding situations and show off a hit methods for combating those unwelcome occurrences. The detailed research of those real-world eventualities supplies treasured classes for imposing fine preventative measures.

Case Learn about 1: The Corroded Keep an eye on Valve

A chemical processing plant skilled a ordinary leak in a regulate valve chargeable for regulating strain within the reactor. Preliminary troubleshooting printed important corrosion within the valve’s frame, led to by way of the competitive nature of the method fluid. The corrosion had weakened the valve’s construction, resulting in a steady build up in leakage over the years. The answer concerned changing the corroded valve with a extra resistant subject material, akin to a high-nickel alloy, and imposing a extra rigorous repairs time table that incorporated common inspection and cleansing of the valve.

The plant additionally switched to a much less corrosive fluid, the place imaginable, decreasing the danger of long term corrosion.

Case Learn about 2: The Riser Machine Failure

An influence plant skilled a vital leak in a riser pipe used for transporting high-pressure steam. The leak originated from a stress-induced crack within the riser’s weld. The troubleshooting concerned meticulous exam of the weld joints, subject material research, and strain trying out to spot the foundation purpose. The restore concerned a complete weld restore process, adopted by way of an intensive strain check to make sure the integrity of the repaired phase.

Next tracking and a elegant inspection time table avoided additional issues. A key takeaway from this example learn about used to be the significance of stringent weld high quality regulate and common inspection of crucial elements.

Case Learn about 3: The Valve Stem Sticking

A water remedy plant encountered a valve stem sticking factor, resulting in intermittent leakage from the regulate valve. The research confirmed that the valve stem used to be collecting deposits over the years, decreasing lubrication and inflicting friction. The answer concerned imposing a preventative repairs technique that incorporated periodic valve stem lubrication and cleansing. In addition they tested the method parameters to spot any elements that would possibly give a contribution to the buildup of deposits.

As well as, the plant investigated choice lubrication ways, which proved to be an efficient technique for combating long term stem sticking and leaks.

Prevention Methods and Analysis

A a hit leak prevention technique will depend on a multi-faceted way, combining proactive repairs with rigorous inspection and tracking. In all 3 case research, the effectiveness of the carried out prevention methods used to be evaluated thru common tracking of the affected elements. The knowledge amassed used to be used to fine-tune the upkeep time table and determine any rising traits or attainable dangers. A complete way is very important to combating leaks.

Key Learnings and Best possible Practices

| Case Learn about | Root Purpose | Troubleshooting | Restore/Resolution | Prevention Technique |

|---|---|---|---|---|

| Corroded Keep an eye on Valve | Competitive procedure fluid | Corrosion inspection | Subject material substitute, advanced repairs | Subject material variety, common inspection |

| Riser Machine Failure | Tension-induced crack in weld | Weld exam, strain trying out | Weld restore, strain trying out | Stringent weld high quality regulate, common inspections |

| Valve Stem Sticking | Deposit accumulation, lowered lubrication | Valve stem lubrication, procedure parameter research | Periodic lubrication, procedure changes | Preventative repairs, lubrication optimization |

Those case research spotlight the crucial significance of a proactive and data-driven method to leak prevention. A complete analysis of attainable reasons, coupled with suitable troubleshooting and service methods, is an important for minimizing downtime and making sure protection.

Subject material Variety and Compatibility: How To Forestall Leaking At Keep an eye on Valve And Riser

Selecting the proper fabrics for regulate valves and risers isn’t just about selecting one thing that appears robust; it is about making sure the long-term well being and protection of all the machine. A subject material incompatible with the method fluid may end up in catastrophic screw ups, inflicting now not most effective pricey upkeep but in addition attainable environmental harm and protection hazards. This cautious variety is paramount for keeping up a competent and environment friendly operation.Settling on fabrics suitable with the method fluid and working stipulations is important to forestall leakage.

A mismatch between subject material and surroundings can cause corrosion, erosion, or different degradation processes, in the long run resulting in leaks and screw ups. This subtle steadiness between subject material houses and the method surroundings immediately affects the machine’s lifespan and general efficiency.

Components Influencing Subject material Variety

Subject material variety for regulate valves and risers hinges on a number of crucial elements. Corrosion resistance, a subject material’s skill to resist the corrosive results of the method fluid, is paramount. Temperature tolerance is every other key attention, as excessive temperatures could cause fabrics to weaken or trade their houses over the years. The working strain and the anticipated carrier lifetime of the apparatus additionally play a an important function in subject material selection.

Moreover, cost-effectiveness and availability also are very important elements within the decision-making procedure.

Lengthy-Time period Efficiency and Steadiness

The long-term efficiency and balance of a subject material are immediately associated with its resistance to degradation. Over the years, fabrics can revel in pressure cracking, pitting, or different varieties of harm because of elements like corrosion, erosion, or fatigue. The particular working stipulations, together with temperature fluctuations, strain diversifications, and publicity to competitive chemical compounds, a great deal affect the fabric’s longevity. Working out the long-term balance of various fabrics within the explicit surroundings is an important for combating pricey screw ups and downtime.

As an example, stainless steels are recognized for his or her corrosion resistance in lots of environments, however their efficiency in high-temperature, high-pressure programs would possibly require specialised alloys.

Comparability of Subject material Homes

The desk underneath illustrates the houses of quite a lot of fabrics appropriate for regulate valves and risers. It is an important to compare the fabric’s houses to the particular necessities of the method surroundings to make sure optimum efficiency and longevity.

| Subject material | Corrosion Resistance | Temperature Tolerance (°C) | Energy | Price |

|---|---|---|---|---|

| Carbon Metal | Reasonable | As much as 450 | Just right | Low |

| Stainless Metal (316L) | Very good | As much as 800 | Just right | Medium |

| Hastelloy C-276 | Very good (competitive chemical compounds) | As much as 650 | Prime | Prime |

| Monel | Very good (sea water, some acids) | As much as 650 | Prime | Medium-Prime |

| Nickel-Primarily based Alloys | Very good (extremely corrosive environments) | As much as 1100 | Prime | Prime |

Regulatory Compliance and Protection

A way of profound accountability hangs heavy over the prevention of leaks in regulate valves and risers. Those methods, essential to numerous operations, call for unwavering adherence to protection protocols and laws. Failing to fulfill those requirements will have devastating penalties, now not simply financially, but in addition with regards to human existence and environmental affect. Working out and meticulously imposing regulatory compliance is paramount for protecting lives and protective our planet.An intensive grab of protection laws is not only an issue of ticking bins; it is about construction a tradition of protection that permeates each and every side of operation, inspection, and upkeep.

This proactive way prevents injuries, minimizes attainable hurt, and instills a deep sense of safety in those that depend on those crucial methods.

Regulatory Necessities for Leakage Prevention

Compliance with regulatory necessities is very important for making sure the protected and dependable operation of regulate valves and risers. Those laws continuously dictate explicit design requirements, subject material specs, and operational procedures to mitigate the hazards related to leaks. This guarantees that each and every side of the machine is constructed with protection as its cornerstone.

Protection Protocols Throughout Inspection, Restore, and Upkeep

Safeguarding staff right through inspection, restore, and upkeep is paramount. A complete set of protection protocols will have to be conscientiously adopted. Those protocols will have to surround private protecting apparatus (PPE), confined area access procedures, and lockout/tagout protocols to forestall unintentional publicity to hazardous stipulations.

Significance of Emergency Reaction Plans for Leakage Incidents

Preparedness for leakage incidents is an important. A well-defined emergency reaction plan, incorporating communique protocols, evacuation procedures, and the deployment of suitable sources, is very important for minimizing the affect of any leakage incident. A swift and arranged reaction is essential to containing the wear and tear and safeguarding the ones concerned.

Desk of Related Protection Rules

The desk underneath Artikels key protection laws and their applicability throughout other industries. Working out those laws and their explicit necessities inside every trade is an important for suitable compliance.

| Protection Legislation | Description | Applicability |

|---|---|---|

| OSHA (Occupational Protection and Well being Management) | Complete set of requirements for employee protection and well being in the US. | Wide variety of industries, together with oil & fuel, production, and building. |

| API (American Petroleum Institute) | Requirements in particular for the oil and fuel trade, protecting apparatus design, operation, and upkeep. | Oil and fuel manufacturing, refining, and transportation. |

| EPA (Environmental Coverage Company) | Rules interested by environmental coverage, together with controlling emissions and dangerous substance releases. | Industries that care for hazardous fabrics, together with chemical processing and production. |

| NFPA (Nationwide Hearth Coverage Affiliation) | Requirements addressing hearth protection and prevention, together with the dealing with of flammable and flamable fabrics. | Industries dealing with flammable fabrics, together with chemical vegetation and garage amenities. |

Ultimate Conclusion

In conclusion, successfully managing regulate valve and riser leaks calls for a multi-faceted way encompassing thorough inspection, systematic troubleshooting, and proactive repairs. Via figuring out the foundation reasons, imposing suitable restore methods, and adopting preventative measures, industries can reduce downtime, be certain protection, and strengthen the entire operational potency in their methods. This information gives a complete roadmap for reaching those objectives.

Person Queries

What are not unusual reasons of regulate valve leaks but even so inaccurate seals?

Unsuitable set up, worn portions, strain fluctuations, and incompatible fabrics too can result in leaks. Working stipulations akin to temperature and move price too can affect the possibility of leakage.

What gear are essential for troubleshooting valve and riser leaks?

Gear wanted for troubleshooting might range in response to the severity and nature of the leak, however usually come with visible inspection gear, strain gauges, leak detection apparatus, and doubtlessly specialised wrenches and dismantling gear.

What are some preventative repairs methods to scale back leakage incidents?

Common repairs schedules, correct set up procedures, and the usage of suitable fabrics for the particular software are key methods to forestall leaks. Design issues for valves and risers will have to additionally think about the possibility of leaks.

How do regulatory necessities have an effect on leakage prevention?

Particular industries and places have laws relating to leakage prevention. Following protection protocols right through inspection, restore, and upkeep is an important, in addition to having emergency reaction plans in position.