How to take away anodizing? This is not a easy process; it is a adventure via more than a few strategies, from mild sanding to competitive chemical baths. Figuring out the method is the most important for holding the integrity of the underlying steel and attaining the required end result. We’re going to discover the other tactics, the professionals and cons of every, and the necessary protection precautions to make sure a a hit and protected end result.

Anodizing, a procedure that coats metals like aluminum and titanium with a protecting layer, on occasion must be got rid of. This information delves into the intricacies of stripping this deposit, overlaying the whole lot from mechanical abrasion to electrochemical reactions. Whether or not you are a seasoned metalworker or a curious newbie, this complete information equips you with the data to take on this difficult process.

Creation to Anodizing Elimination

Anodizing, a well-liked floor remedy for metals, considerably complements their sturdiness and aesthetic attraction. Figuring out the method and the more than a few strategies for its removing is the most important for keeping up or repurposing steel elements in various programs. This information is necessary for each execs and hobbyists alike, enabling knowledgeable selections about subject material dealing with and possible long term adjustments.The method of anodizing comes to growing a skinny, laborious, and protecting oxide layer at the steel floor.

This accretion is shaped by means of an electrochemical procedure, generally involving the steel immersed in an electrolyte answer and subjected to an instantaneous electric present. This managed oxidation strengthens the fabric, making a layer that is proof against corrosion and abrasion. Various kinds of anodizing lead to various ranges of hardness and aesthetic qualities, adapted to express wishes.

Anodizing Procedure and Varieties

Anodizing is an electrochemical procedure the place a steel is immersed in an electrolyte answer and an instantaneous electric present is carried out. This reasons an oxidation response, making a thicker oxide layer at the steel’s floor. This accretion is way more sturdy than the bottom steel. The kind of anodizing procedure determines the houses of the oxide layer.

Forms of Anodizing

More than a few anodizing strategies exist, every adapted to express necessities. Those come with:

- Arduous Anodizing: This procedure produces a considerably tougher and extra abrasion-resistant oxide layer in comparison to different strategies. The ensuing layer is terribly dense, providing awesome coverage in opposition to put on and tear, making it preferrred for programs requiring top sturdiness.

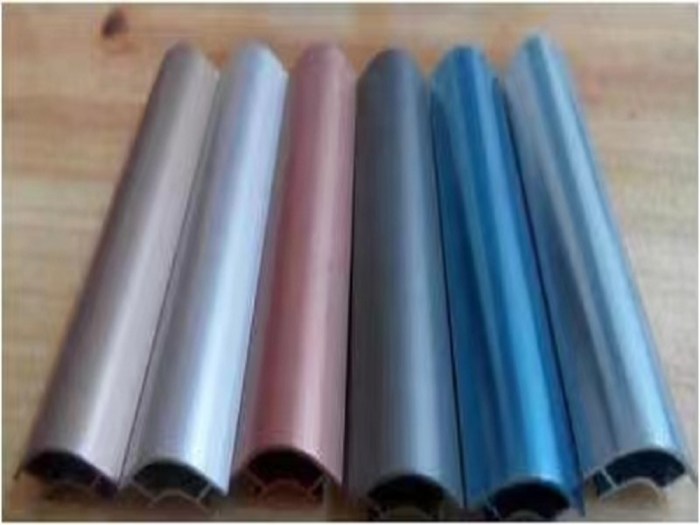

- Ornamental Anodizing: This sort of anodizing makes a speciality of bettering the classy houses of the steel. It comes to coloring the oxide layer, bearing in mind a variety of colourful hues and finishes, steadily used for ornamental programs or to strengthen the visible attraction of the element.

- Dyeing Anodizing: This system comes to dyeing the oxide layer after it’s been created. This provides colour and visible attraction to the steel floor. That is steadily utilized in ornamental programs to offer the steel a fantastic and sturdy end. The colour is infused into the oxide layer all over or after the anodizing procedure.

Not unusual Anodized Fabrics

Anodizing is incessantly carried out to metals like aluminum, titanium, and magnesium. The inherent houses of those metals, together with their light-weight nature and corrosion resistance, cause them to preferrred for a variety of programs, from aerospace elements to shopper items. The anodizing procedure complements those houses, additional expanding the suitability for particular roles.

Causes for Anodizing Elimination

There are more than a few the reason why one may want to take away anodizing from a steel element. Those come with:

- Repurposing: The unique meant use of the element might exchange, requiring the removing of the anodizing layer to reveal the bottom steel for a brand new utility.

- Repairing Injury: In some circumstances, harm to the anodized layer might necessitate its removing to permit for correct restore or recovery.

- Making improvements to Compatibility: The removing of anodizing could also be vital to give a boost to compatibility with next therapies or processes.

- Steel Research: Casting off the anodizing layer is steadily required for metallurgical research, bearing in mind exam of the underlying base steel construction.

Strategies for Casting off Anodizing

Other strategies are to be had for taking out anodizing, every with its personal set of benefits and downsides.

| Means | Benefits | Disadvantages | Applicability |

|---|---|---|---|

| Mechanical Stripping | Quite reasonably priced and readily to be had equipment | Probably damages the bottom steel, steadily leaving asymmetric surfaces | Appropriate for small-scale removing or when exact floor end isn’t the most important |

| Chemical Stripping | May also be efficient for taking out anodizing with out in depth harm to the bottom steel | May also be time-consuming and might require specialised chemical substances and protection precautions | Suitable for extra subtle elements or scenarios the place floor integrity is essential |

| Electrolytic Stripping | Actual keep watch over over the removing procedure | Calls for specialised apparatus and experience, doubtlessly upper prices | Ideally suited for complicated geometries or when constant removing is vital |

Mechanical Elimination Strategies: How To Take away Anodizing

Unveiling the world of anodizing removing, we now delve into the sensible sides of mechanical strategies. Those tactics, whilst steadily extra competitive than chemical strategies, be offering an instantaneous strategy to stripping the anodizing layer. Figuring out their intricacies and possible pitfalls is the most important for a a hit end result.

Sanding

Sanding, a basic mechanical procedure, comes to the use of abrasive fabrics to put on away the anodizing layer. Other grit sizes be offering various ranges of aggressiveness, impacting the general end result. Actual keep watch over over the sanding procedure is essential to attaining a enough end result with out destructive the underlying substrate.

- Steps Concerned: Preliminary steps contain assessing the skin house and settling on the suitable grit sandpaper. Next steps come with making use of even power all over sanding, making sure a constant manner throughout all of the floor. Common inspection of the paintings is necessary to keep away from unintentional harm. In the end, thorough cleansing gets rid of the loosened anodizing debris.

- Effectiveness and Potency: Sanding’s effectiveness is dependent closely at the grit dimension and the operator’s talent. Finer grits yield smoother effects, however require extra time. Whilst sanding may also be time-consuming, it permits for a top stage of keep watch over over the general end.

Grinding

Grinding, a extra competitive manner, makes use of rotating abrasive equipment to take away the anodizing layer. The depth of grinding can range considerably in response to the device’s velocity and the kind of abrasive used.

- Steps Concerned: The preliminary step comes to settling on the suitable grinding device and abrasive. Next steps come with managed motion around the floor to keep away from over the top subject material removing or gouging. Cautious tracking is vital to stop overheating of the substrate. In the end, cleansing the skin gets rid of the loosened debris.

- Effectiveness and Potency: Grinding is usually extra environment friendly than sanding for massive spaces, however it may end up in extra pronounced scratches or floor imperfections if now not carried out in moderation. The velocity and aggressiveness of the grinding procedure considerably affect the end result.

Abrasion

Abrasion, a broader time period, encompasses a big selection of tactics using abrasive fabrics to take away the anodizing layer. From the use of specialised brushes to blasting with sand or different abrasives, every manner has its particular benefits and downsides.

- Steps Concerned: Preliminary steps contain comparing the skin and opting for the suitable abrasive subject material. Next steps come with controlling the abrasive’s depth and course. Common tracking of the method is very important to keep away from important harm to the bottom subject material. In the end, thorough cleansing gets rid of the loosened debris.

- Effectiveness and Potency: Abrasive strategies are usually efficient, however their potency varies considerably in response to the precise methodology. For example, sandblasting is extremely environment friendly however can produce rougher finishes. Cautious attention of the required end result and the kind of abrasive is the most important.

Comparability Desk

| Means | Equipment Required | Time Required | End result High quality |

|---|---|---|---|

| Sanding | Sandpaper, sanding block, protecting tools | Variable, will depend on floor house and grit dimension | In most cases top, can reach clean finishes with finer grits |

| Grinding | Grinding device, abrasive wheels, protecting tools | In most cases sooner than sanding for massive spaces | May also be much less exact, possible for scratches if now not managed |

| Abrasion | Abrasive fabrics (sand, brushes), specialised apparatus (sandblaster) | Variable, will depend on the methodology and floor house | Extremely environment friendly however might yield rougher finishes, will depend on the process |

Possible Drawbacks and Obstacles, How to take away anodizing

Mechanical strategies can introduce floor imperfections, scratches, and even harm the underlying substrate if now not carried out meticulously. The extent of keep watch over required may also be difficult for much less skilled operators. Moreover, those strategies steadily generate important quantities of mud and particles, necessitating suitable protection measures.

Protection Precautions

Suitable non-public protecting apparatus (PPE) is the most important all over mechanical removing. Eye coverage, mud mask, and gloves are crucial to stop inhalation of abrasive debris and accidents. Make sure that correct air flow to mitigate the unfold of mud. When the use of energy equipment, at all times apply producer directions and prioritize protection.

Chemical Elimination Strategies

Unveiling the intricate dance of chemical substances to softly strip away the anodized layer, chemical strategies be offering a special strategy to anodizing removing. Those strategies depend on particular chemical reactions to dissolve the anodized layer, steadily offering a cleaner and extra managed end result in comparison to mechanical strategies. On the other hand, the usage of chemical substances necessitates meticulous protection protocols and conscious attention of environmental affect.Chemical anodizing removing comes to using particular chemical answers that react with the anodized aluminum floor.

The selected answer dictates the suitable chemical response and the next end result. Figuring out those chemical reactions is the most important for successfully using those strategies and mitigating possible dangers.

Chemical Reactions in Anodizing Elimination

The method of chemical anodizing removing hinges on chemical reactions that spoil down the anodized aluminum layer. Those reactions are normally in response to oxidation-reduction processes, the place the anodized aluminum is decreased and the chemical reagent is oxidized. The particular response mechanisms rely on the kind of chemical answer hired. For example, the use of sturdy acids can result in the dissolution of the aluminum oxide layer, successfully taking out the anodizing.

This procedure wishes cautious keep watch over to stop over the top subject material loss. Examples come with the usage of sulfuric acid or hydrofluoric acid answers.

Other Chemical Answers and Their Packages

More than a few chemical answers are hired for anodizing removing, every with its particular programs and obstacles. The choice will depend on the required end result, the thickness of the anodizing, and the kind of aluminum alloy. Some answers are extra appropriate for particular anodizing sorts, like laborious anodizing, whilst others are higher fitted to cushy anodizing. This cautious variety minimizes possible harm to the underlying steel.

Not unusual Chemical Reagents for Anodizing Elimination

- Sulfuric acid (H 2SO 4): A extensively used chemical for dissolving aluminum oxide, steadily hired in taking out more than a few kinds of anodizing. It is a robust acid that calls for cautious dealing with.

- Hydrofluoric acid (HF): This extremely corrosive acid is steadily used along with different chemical substances to successfully take away anodizing. Its top reactivity makes it bad to maintain.

- Oxalic acid (H 2C 2O 4): Recognized for its skill to dissolve aluminum oxide, oxalic acid gives a gentler manner in comparison to sulfuric or hydrofluoric acid, doubtlessly minimizing harm to the bottom steel.

- Sodium hydroxide (NaOH): A robust alkali that may additionally dissolve aluminum oxide, normally utilized in particular anodizing removing situations.

Steps Concerned with The use of Chemical Answers

The stairs for the use of chemical answers for anodizing removing range relying at the particular answer and the required end result. On the other hand, a common process comes to cautious preparation, exact utility, and regulated response instances. All the time apply the precise directions supplied by means of the producer of the selected answer. Protection apparatus and procedures must at all times be adopted to mitigate possible hazards.

Comparability of Chemical Answers

| Resolution | Process | Protection Precautions | Environmental Have an effect on |

|---|---|---|---|

| Sulfuric Acid | Immersion in a managed answer at a particular temperature and focus for a collection length. | Put on suitable non-public protecting apparatus (PPE), together with gloves, goggles, and a lab coat. Paintings in a well-ventilated house. | Sulfuric acid is an environmental pollutant, requiring correct disposal the right way to save you water contamination. |

| Hydrofluoric Acid | Immersion in a in moderation managed answer at a particular temperature and focus for a collection length. Incessantly utilized in mixture with different chemical substances. | Excessive warning is needed when dealing with hydrofluoric acid because of its top reactivity and possible for serious burns. Paintings in a well-ventilated house with correct PPE. | Hydrofluoric acid poses a vital environmental chance, requiring specialised disposal the right way to save you contamination. |

| Oxalic Acid | Immersion in a managed answer at a particular temperature and focus for a collection length. Generally more secure to maintain than sulfuric or hydrofluoric acid. | Use suitable PPE, together with gloves, goggles, and a lab coat. Paintings in a well-ventilated house. | Oxalic acid, despite the fact that much less hazardous than different chemical substances, nonetheless wishes correct disposal to keep away from environmental contamination. |

Possible Hazards of Chemical Elimination Strategies

Chemical removing strategies provide inherent dangers because of the usage of sturdy chemical substances. Those hazards come with the possibility of pores and skin burns, eye harm, breathing problems, and much more serious penalties. Mistaken dealing with or insufficient protection precautions can result in important accidents. All the time prioritize protection and apply the precise tips supplied by means of the producer. Correct air flow and suitable non-public protecting apparatus (PPE) are the most important for mitigating dangers.

Electrochemical Elimination Strategies

Unlocking the secrets and techniques to anodizing removing, this segment dives into electrochemical strategies, an impressive manner with exact keep watch over over the method. Those strategies leverage the foundations of electrochemistry to selectively dissolve the anodized layer, providing a managed and steadily centered manner. Figuring out the specifics of kit, fabrics, and procedures is essential to mastering this method.

Theory of Electrochemical Anodizing Elimination

Electrochemical anodizing removing will depend on an electrochemical response the place the anodized layer acts because the anode in an electrolytic mobile. Making use of a managed present and suitable electrolyte dissolves the aluminum oxide layer. This managed dissolution permits for exact removing, minimizing harm to the underlying substrate. The method is in response to Faraday’s regulations of electrolysis, the place the quantity of subject material dissolved is immediately proportional to the present and the time.

Apparatus and Fabrics

Imposing electrochemical anodizing removing calls for particular apparatus and fabrics. An influence provide in a position to turning in a managed DC present is very important. Crucially, the facility provide will have to be adjustable to permit for fine-tuning of the present. The electrolyte, steadily an acid answer, is every other key element. Correct number of the electrolyte is the most important for each potency and protection.

An acceptable container for the electrolytic answer may be vital, making sure chemical resistance and suitable dimension. The paintings piece, the phase with the anodizing, is immersed within the electrolyte, and electrodes are located appropriately.

Step-by-Step Process

A scientific manner is necessary for electrochemical removing. First, make sure that the paintings piece is securely located throughout the electrolytic answer, and the electrodes are correctly positioned. Secondly, in moderation modify the DC present to the required stage. Track the method carefully all through the removing to keep away from over-dissolution or harm to the underlying subject material. Common measurements and visible inspections are the most important for making sure the method is continuing as deliberate.

In the end, as soon as the anodizing is got rid of, totally rinse the paintings piece with deionized water and neutralize any residual electrolyte.

Benefits of Electrochemical Elimination

This system gives a number of advantages over different tactics. It supplies very good keep watch over over the removing procedure, bearing in mind exact removing of the anodizing. Moreover, it minimizes harm to the underlying subject material, keeping up the unique integrity of the bottom steel. The managed dissolution of the oxide layer ends up in a cleaner and extra predictable removing end result.

Disadvantages of Electrochemical Elimination

Whilst fine, electrochemical strategies have obstacles. The method may also be time-consuming, in particular for thick anodizing layers. Actual keep watch over over parameters like present and time is important, requiring cautious tracking. Protection measures also are paramount because of the usage of corrosive chemical substances.

Elements Influencing Effectiveness

A number of elements have an effect on the luck of electrochemical anodizing removing. The kind of electrolyte used, its focus, and the temperature considerably affect the speed of dissolution. The carried out present and its length are vital parameters influencing the intensity and uniformity of removing. The skin situation of the paintings piece and the presence of any contaminants additionally play a job.

Comparability with Different Elimination Strategies

Electrochemical removing strategies are incessantly when put next with mechanical and chemical strategies. Mechanical strategies may cause harm to the underlying subject material, while chemical strategies won’t give you the similar stage of precision or keep watch over. Electrochemical strategies strike a stability between velocity, precision, and subject material preservation, steadily presenting a extra subtle answer.

Concerns for Explicit Fabrics

Selecting the proper anodizing removing manner is the most important for holding the integrity of the underlying subject material. Other metals react otherwise to more than a few removing tactics, making cautious variety paramount. Figuring out the fabric’s houses and the nuances of every manner is essential to a a hit and protected removing procedure.The number of the suitable removing manner is dependent closely at the subject material’s houses and the required end result.

This segment delves into the precise demanding situations and answers for taking out anodizing from commonplace fabrics like aluminum and titanium, and Artikels the significance of choosing the right manner in response to subject material thickness. Attention of those elements guarantees environment friendly and efficient removing, minimizing possible harm to the substrate.

Subject matter-Explicit Demanding situations and Answers

Other fabrics provide distinctive demanding situations all over anodizing removing. Aluminum, for example, is often anodized, however its particular alloy composition and thickness have an effect on the suitability of more than a few strategies. Titanium, recognized for its energy and corrosion resistance, calls for cautious attention because of its inherent houses. Different metals may also provide their very own set of complexities. Each and every subject material’s traits dictate the most productive plan of action.

Aluminum Anodizing Elimination

Aluminum is a well-liked selection for anodizing because of its very good corrosion resistance and aesthetic attraction. On the other hand, the precise alloy and thickness of the anodized layer considerably affect the removing procedure. Competitive chemical strategies may compromise the integrity of the underlying aluminum, whilst mechanical strategies may not be efficient sufficient. Correctly settling on the removing manner is very important to deal with the integrity of the aluminum substrate.

Titanium Anodizing Elimination

Titanium’s top energy and corrosion resistance make it a precious subject material. On the other hand, its reactivity to positive chemical substances can complicate anodizing removing. Mechanical strategies could also be most well-liked because of their decreased chance of subject material harm. The selected manner must believe the precise titanium alloy and the required stage of precision.

Different Steel Anodizing Elimination

More than a few different metals may also be anodized, every with its distinctive houses. The number of the removing manner is determined by the precise steel and its alloy composition. As an example, copper, zinc, or nickel might require adapted approaches to keep away from harm to the substrate. Detailed wisdom of the steel’s traits is the most important for efficient and protected removing.

Suitability of Elimination Strategies

The effectiveness of various anodizing removing strategies varies considerably relying at the subject material. A scientific manner is necessary.

| Subject matter | Means | Execs | Cons |

|---|---|---|---|

| Aluminum | Chemical | In most cases efficient, moderately rapid | May also be competitive, possible for subject material harm |

| Aluminum | Mechanical | Much less competitive, just right for skinny layers | May also be time-consuming, will not be efficient for thick layers |

| Titanium | Mechanical | Minimizes chemical interplay, just right for precision | May also be labor-intensive, will not be efficient for thick layers |

| Titanium | Electrochemical | May also be managed, appropriate for particular programs | Would possibly require specialised apparatus, possible for asymmetric removing |

| Copper | Chemical | Could also be efficient for positive copper alloys | Possible for subject material harm, want for correct protection measures |

Impact of Subject matter Thickness

Subject matter thickness considerably affects the number of the anodizing removing manner. Thicker layers require extra competitive strategies, corresponding to chemical or electrochemical processes. Thinner layers may also be got rid of extra successfully with mechanical strategies. A stability will have to be struck between the effectiveness of the process and the possibility of harm to the underlying substrate. For example, a skinny layer of anodized aluminum may well be successfully got rid of with a mechanical manner.

On the other hand, a thick layer of anodized titanium may necessitate a extra specialised electrochemical strategy to save you subject material degradation.

Protection and Environmental Have an effect on

Casting off anodizing, whilst the most important for more than a few programs, necessitates cautious attention of protection and environmental implications. Correct protocols and accountable disposal practices are paramount to minimizing dangers to each human well being and the surroundings. Figuring out the precise hazards related to every removing manner is essential to enforcing efficient protection measures.

Protection Precautions All the way through Elimination Strategies

Protected dealing with of chemical substances and gear is very important all through the anodizing removing procedure. Protecting tools, together with gloves, eye coverage, and respirators, must be worn always. Air flow techniques will have to be ok to stop the buildup of destructive fumes and vapors. Designated spaces for chemical garage and disposal must be obviously marked and maintained in keeping with protection laws.

Correct coaching and consciousness of possible hazards are vital to minimizing dangers.

Environmental Have an effect on of Elimination Strategies

The environmental affect of anodizing removing strategies varies relying at the tactics hired. Mechanical strategies, whilst steadily much less hazardous, can generate important waste, in particular when coping with large-scale operations. Chemical and electrochemical strategies make the most of answers that, if improperly controlled, can introduce pollution into the encompassing atmosphere. Figuring out the precise environmental issues of every manner is necessary for sustainable practices.

Accountable Disposal Procedures

Accountable disposal of chemical answers and waste fabrics is the most important to minimizing environmental hurt. Chemical answers must be neutralized and disposed of in keeping with native laws and environmental tips. Waste fabrics, together with sludge and residues, must be treated with care and disposed of in designated waste streams. Compliance with all acceptable laws and correct documentation of disposal procedures are crucial sides of accountable follow.

Possible Well being Hazards

Publicity to chemical substances utilized in anodizing removing can pose important well being dangers. Inhalation of fumes, pores and skin touch with corrosive answers, and ingestion of infected fabrics can result in more than a few well being problems. Examples come with breathing issues, pores and skin inflammation, and eye harm. Common well being exams and correct non-public protecting apparatus (PPE) utilization are necessary in mitigating those dangers.

Desk: Protection Precautions and Environmental Concerns

| Means | Protection Precautions | Waste Disposal | Environmental Have an effect on |

|---|---|---|---|

| Mechanical Elimination | Put on protection glasses, gloves, and suitable breathing coverage. Make sure that ok air flow. | Cast off abrasives and scrap steel in designated boxes. Make sure that compliance with native laws. | Minimum environmental affect if correct waste control is adopted. Possible for noise and dirt air pollution. |

| Chemical Elimination | Put on complete PPE (gloves, goggles, respirator). Paintings in a well-ventilated house. Keep away from pores and skin touch. | Neutralize chemical answers in keeping with native laws sooner than disposal. Correctly label and retailer waste. | Possible for water contamination if chemical substances aren’t correctly neutralized and disposed of. Hazardous waste era. |

| Electrochemical Elimination | Use suitable protection apparatus (gloves, goggles, and apron). Paintings in a well-ventilated house. Make sure that correct grounding. | Correctly neutralize and eliminate electrolyte answers. Adhere to native laws for hazardous waste disposal. | Electrolyte answers may also be destructive to aquatic existence if improperly disposed of. Possible for electric hazards. |

Apparatus and Equipment

Selecting the proper apparatus and equipment is the most important for environment friendly and protected anodizing removing. Correct variety guarantees minimum subject material harm, optimized removing velocity, and adherence to protection protocols. This segment main points the crucial equipment for every removing manner, emphasizing their options and the standards for efficient device variety. Figuring out those nuances empowers you to optimistically take on anodizing removing tasks.

Mechanical Elimination Strategies Apparatus

Mechanical strategies steadily contain abrasion or grinding to take away the anodized layer. Settling on the right kind abrasive subject material and gear is necessary to keep away from destructive the underlying steel. Suitable grit dimension is very important for attaining desired effects with out over the top subject material loss. Believe the hardness of the substrate subject material and the thickness of the anodizing layer when opting for the device and its parameters.

- Grinders: More than a few kinds of grinders, together with attitude grinders, belt sanders, and rotary equipment, are used. Perspective grinders be offering maneuverability for exact paintings, whilst belt sanders are appropriate for better floor spaces. Rotary equipment with other abrasive attachments are helpful for attaining tight areas.

- Abrasive Fabrics: The number of abrasive fabrics, like sandpaper, grinding wheels, or sharpening compounds, dictates the aggressiveness of the removing procedure. Other grit sizes correspond to various levels of floor roughness. For example, finer grit sandpaper will produce a smoother end.

- Protecting Equipment: Eye coverage, mud mask, and respirators are crucial for combating inhalation of abrasive debris and making sure employee protection.

Chemical Elimination Strategies Apparatus

Chemical strategies make use of particular answers to dissolve the anodizing layer. Suitable boxes and protection apparatus are paramount. The collection of container subject material will depend on the chemical used and the possibility of reactivity.

- Packing containers: Appropriate boxes, corresponding to glass or plastic beakers, tanks, or trays, are required. Subject matter compatibility with the chemical is important to stop contamination or response.

- Stirring Gadgets: Stirring or agitating the answer guarantees even distribution of the chemical and promotes uniform removing of the anodizing layer.

- Protection Apparatus: Chemical resistant gloves, protection glasses, and aprons are crucial to stop pores and skin touch, eye inflammation, and clothes harm.

- Measuring Gadgets: Measuring gadgets, like graduated cylinders, beakers, and pH meters, are vital for correct chemical answers and keep watch over. Keeping up the right kind focus of chemical substances is necessary for efficient removing and combating harm to the underlying steel.

Electrochemical Elimination Strategies Apparatus

Electrochemical strategies use {an electrical} present to dissolve the anodizing layer. Explicit apparatus is the most important for this procedure.

- Energy Provide: A DC energy provide with adjustable voltage and present controls is wanted. Actual keep watch over of the present is the most important to stop harm to the substrate.

- Electrodes: Electrodes of suitable subject material (e.g., stainless-steel, graphite) are required for environment friendly present waft and to keep away from unwanted facet reactions.

- Electrolyte Resolution: An acceptable electrolyte answer is vital to facilitate the electrochemical response. The choice will depend on the fabric being handled.

- Protection Apparatus: Suitable protection apparatus, together with gloves, eye coverage, and a correctly grounded paintings house, is the most important to keep away from electric hazards and chemical publicity.

Apparatus Variety Standards

Selecting the best apparatus comes to cautious attention of things like the fabric being handled, the thickness of the anodizing layer, the required floor end, and protection laws. Value-effectiveness may be a key issue. Matching the apparatus to the duty is the most important.

Apparatus and Equipment Desk

| Means | Instrument | Description | Utilization |

|---|---|---|---|

| Mechanical | Perspective Grinder with abrasive disc | Rotating device with a slicing disc. | Casting off thick anodized layers from vast surfaces. |

| Chemical | Glass beaker | Transparent glass container for chemical answers. | Retaining and combining chemical answers. |

| Electrochemical | DC Energy Provide | Adjustable voltage and present keep watch over. | Offering managed electric present for anodizing removing. |

Repairs and Care

Common upkeep and correct care of kit are crucial to make sure optimum efficiency and protection. This comprises checking for put on and tear, cleansing, and storing apparatus correctly. Following producer’s tips is the most important for prolonging apparatus lifespan.

Conclusive Ideas

In conclusion, taking out anodizing comes to cautious attention of the fabric, the selected manner, and the most important protection measures. From mechanical abrasion to chemical answers and electrochemical processes, the information gives a roadmap for attaining a hit removing. Take note, protection and correct disposal procedures are paramount all through all of the procedure. By way of figuring out the benefits and downsides of every methodology, you’ll choose the process best possible suited for your particular wishes and subject material.

In style Questions

What are the most typical fabrics that get anodized?

Aluminum and titanium are standard possible choices, however different metals can be anodized.

What are the prospective well being hazards related to chemical removing?

Many chemical substances utilized in anodizing removing are hazardous. All the time put on suitable protection tools and apply the directions in moderation.

Are you able to suggest a protected manner for taking out anodizing from aluminum?

Mechanical strategies like sanding are steadily appropriate for aluminum, however chemical strategies will also be an possibility. Seek the advice of sources for detailed directions.

What is the environmental affect of various anodizing removing strategies?

Chemical strategies could have a vital environmental affect, so correct disposal procedures are the most important. Mechanical strategies generally have a smaller environmental footprint.