Find out how to measure shaft size outboard motor appropriately is the most important for boat house owners. An exact dimension guarantees compatibility together with your boat and propeller, combating expensive replacements and doable injury. Working out the significance of this apparently easy process can prevent complications and make sure a clean crusing revel in. From choosing the right equipment to troubleshooting not unusual dimension problems, this information walks you via each and every step of the method.

This complete information covers the entirety from working out the importance of correct shaft size dimension to detailed explanations of more than a few strategies and doable pitfalls. We’re going to equip you with the information and equipment to with a bit of luck measure your outboard motor shaft, making sure optimum efficiency and longevity.

Advent to Measuring Outboard Motor Shaft Period

Getting the appropriate shaft size on your outboard motor is like discovering the easiest pair of denims – it is all about are compatible. An exact dimension is not just about aesthetics; it is the most important for optimum efficiency and longevity of your treasured boat-powered gadget. Mismatched shaft size can lead to a complete host of issues, from diminished potency to doubtlessly severe injury.

So, let’s dive into why this apparently easy dimension is so necessary.Exact dimension of outboard motor shaft size is essential for right kind boat compatibility and engine efficiency. The shaft’s size without delay affects how effectively the motor transmits energy to the water, influencing the boat’s velocity, gasoline potency, and total dealing with. Call to mind it because the engine’s connection to the water; a mismatched size is like seeking to pressure a automotive with the unsuitable dimension transmission.

Significance of Correct Shaft Period Dimension

Flawed shaft size can result in a cascade of issues. Deficient alignment between the motor and the boat’s pressure machine may end up in diminished energy output, larger vibration, and untimely put on and tear on the most important parts. This is not near to just a little bit of additional noise; it may be the variation between a clean, stress-free boating revel in and one stuffed with irritating problems.

Eventualities The place Flawed Shaft Period Can Purpose Problems

The use of an incorrectly sized shaft can result in various issues. A shaft that is too quick may no longer have interaction with the decrease unit correctly, inflicting the motor to fight and doubtlessly overheat. Conversely, a shaft that is too lengthy may consequence within the propeller being submerged within the water much less successfully, affecting the boat’s velocity and gasoline economic system. Those issues don’t seem to be simply minor annoyances; they may be able to result in expensive upkeep and considerably diminish your boating enjoyment.

Doable Penalties of The use of an Incorrectly Sized Shaft

The effects of the usage of an fallacious shaft size are vital and may also be expensive. A poorly matched shaft may cause a motor to vibrate violently, resulting in doable injury to the motor housing and different essential parts. This can result in expensive upkeep or even render the motor unusable. Consider attempting to make use of a couple of scissors to chop via a brick wall – that is necessarily what you are doing with an incompatible shaft.

Comparability of Outboard Motor Varieties and Conventional Shaft Period Levels

| Outboard Motor Kind | Conventional Shaft Period Vary (inches) |

|---|---|

| Small, Leisure (4-15 hp) | 10-24 |

| Mid-Vary (15-40 hp) | 12-30 |

| Huge, Efficiency (40 hp+) | 24-48 |

This desk supplies a basic tenet for shaft size levels, however the explicit size depends upon the precise fashion and the boat’s design. At all times seek the advice of the producer’s specs on your specific outboard motor and boat aggregate. Do not be a DIY crisis!

Equipment and Apparatus Wanted for Dimension

Alright, intrepid outboard motor fanatics! In a position to delve into the interesting global of actual shaft size resolution? We aren’t simply measuring; we are embarking on a quest for the easiest are compatible, a adventure that calls for the appropriate equipment. With out the appropriate equipment, you are simply winging it, and everyone knows how effectively that works out!Armed with the right kind tools, you are able to with a bit of luck take on any shaft size dimension, from the standard little 4-horsepower to the mighty 150-plus behemoths.

This phase will equip you with the vital equipment and information to reach correct measurements, making sure your outboard motor plays at its top.

Crucial Measuring Equipment

Correct dimension is paramount. Choosing the proper equipment will resolve the accuracy of your ultimate shaft size dimension. Those equipment, like trusty sidekicks, will assist you to navigate this dimension project.

- A top of the range virtual caliper is your splendid pal. Its actual readings, continuously correct to 0.01 inches or millimeters, are the most important for making sure your outboard motor is an ideal are compatible. Search for fashions with a strong building and transparent, easy-to-read presentations.

- A competent metal tape measure, ideally one with metric and imperial measurements, supplies fast and easy size measurements. Its versatility makes it a precious addition for your toolkit. Make a selection a tape measure with a strong, non-stretching subject material for dependable measurements. A retractable tape measure is much more handy, taking into consideration garage and smooth deployment.

- A strong, non-flexible measuring rod or ruler, continuously with a graduated scale, is your subsequent dependable selection. It’s appropriate for measurements which can be lengthy sufficient and can give a correct dimension for the outboard shaft. For higher accuracy, search for a measuring rod constituted of top of the range subject material that does not bend or distort underneath force.

Evaluating Other Measuring Equipment

Other equipment cater to other wishes. A virtual caliper excels at actual readings, preferrred for small increments. Tape measures, alternatively, are higher for higher measurements. Measuring rods be offering a simple means for sure lengths. Make a selection the device splendid suited for the task to hand, making sure the required accuracy.

- Virtual calipers be offering essentially the most precision, however they may be able to be dearer than tape measures. They are perfect for essential measurements, the place fractions of a millimeter subject.

- Tape measures supply versatility, masking quite a lot of lengths, however they may not all the time be as actual as virtual calipers.

- Measuring rods are ideal for easy, easy measurements over a substantial distance. They provide a easy but dependable means.

Calibration and Accuracy

Calibration is the most important for making sure the accuracy of your measuring equipment. Identical to tuning a musical tool, you wish to have to calibrate your measuring equipment to make sure their reliability. Uncalibrated equipment are like a automotive with out right kind alignment – they result in mistakes for your measurements.

Calibration guarantees your measurements are correct, and mistakes are minimized.

- Incessantly calibrate your measuring equipment to handle their accuracy. That is like acting regimen repairs in your automotive; it prevents vital issues down the street.

- Use calibrated equipment to make sure constant measurements and keep away from expensive errors. At all times double-check the calibration dates to make sure accuracy.

Device Variety Desk

This desk summarizes the really useful equipment for more than a few shaft size dimension eventualities.

| Device | Description | Suitable Use |

|---|---|---|

| Virtual Caliper | Top precision, virtual readout | Exact measurements of small shaft sections, wonderful changes |

| Metal Tape Measure | Flexible, long-range dimension | Measuring the full size of the shaft |

| Measuring Rod | Easy, easy, long-range | Measuring shaft size in eventualities the place precision is much less essential |

Strategies for Measuring Outboard Motor Shaft Period

Ah, the fantastic quest for actual outboard motor shaft dimensions! This is not rocket science, however it is indisputably extra actual than guessing what number of beers you’ll be able to chug earlier than your boat capsizes. Working out the more than a few strategies, from the straightforward to the reasonably extra subtle, is vital to getting the appropriate are compatible on your watercraft. Let’s dive in!

Usual Strategies for Shaft Period Dimension

Understanding find out how to appropriately measure your outboard motor shaft size is the most important for right kind set up and compatibility. Other strategies be offering various levels of precision and simplicity of use. A not unusual thread amongst all strategies is the desire for a gentle hand and a prepared eye, and, after all, the appropriate equipment.

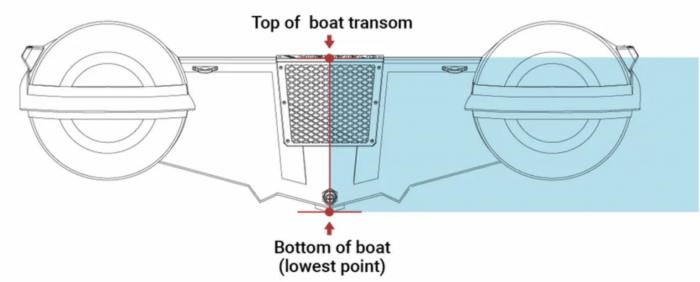

The use of a Ruler

A easy ruler, continuously lost sight of on the earth of high-tech measurements, is strangely efficient for elementary shaft size estimations. Place the ruler along the shaft, making sure it is perpendicular to the shaft’s axis. Moderately align the ruler’s 0 mark with one finish of the shaft. The mark at the ruler the place the opposite finish of the shaft aligns is the dimension.

A well-lit space and a strong floor are your splendid pals right here. In case you are measuring a tough curve, chances are you’ll want to use a immediately edge to make sure accuracy. This system is splendid for fast assessments and ballpark figures.

Using a Caliper

For a extra subtle method, believe the usage of a caliper. A caliper, with its actual jaws, supplies a extra correct studying in comparison to a ruler. First, moderately place the caliper’s jaws in opposition to the shaft ends, making sure the caliper is perpendicular to the shaft’s axis. Then, learn the dimension displayed at the caliper’s scale. This system is perfect for figuring out actual dimensions and will deal with reasonably curved or abnormal shaft shapes.

Comparability of Dimension Strategies

| Way | Accuracy | Precision | Ease of Use | Price ||—————-|————|————|————|————|| Ruler | Low | Low | Top | Low || Caliper | Top | Top | Reasonable | Reasonable |

Detailed Rationalization of Ruler and Caliper Use

Ruler

A easy ruler, continuously lost sight of, is strangely efficient for elementary shaft size estimations.

Place the ruler along the shaft, making sure it is perpendicular to the shaft’s axis. Moderately align the ruler’s 0 mark with one finish of the shaft. The mark at the ruler the place the opposite finish of the shaft aligns is the dimension.

Caliper

A caliper, with its actual jaws, supplies a extra correct studying in comparison to a ruler.

First, moderately place the caliper’s jaws in opposition to the shaft ends, making sure the caliper is perpendicular to the shaft’s axis. Then, learn the dimension displayed at the caliper’s scale. Make certain that the caliper is accurately calibrated for correct measurements. In case you are coping with a curved or abnormal shaft, a virtual caliper may well be extra appropriate for actual readings.

Components Affecting Shaft Period Dimension Accuracy

Measuring your outboard motor shaft’s size is the most important for right kind boat operation and motor repairs. However identical to a finely tuned engine, actual dimension is dependent upon extra than simply the equipment you employ. Environmental stipulations and human error can throw a wrench for your best-laid plans, resulting in misguided readings. Let’s dive into the sneaky components that may impact your measurements, and find out how to keep away from the “shaft-length-measurement-mishaps.”

Environmental Components Affecting Accuracy, Find out how to measure shaft size outboard motor

Environmental stipulations, like a fickle climate trend, can considerably have an effect on the accuracy of your shaft size dimension. Temperature fluctuations, humidity ranges, or even air force may cause the steel shaft to make bigger or contract, skewing your effects. Call to mind it like seeking to measure a scorching canine in a sauna – it is going to be just a little longer than you are expecting!

Temperature Fluctuations

Temperature adjustments may cause the shaft subject material to make bigger or contract, a phenomenon referred to as thermal growth. Which means that a shaft measured on a scorching day will seem reasonably longer than the similar shaft measured on a chilly day. A ten-degree Celsius exchange can result in a noticeable, even though no longer drastic, distinction within the dimension. This is the reason it’s a must to handle a constant temperature all the way through the dimension procedure.

For instance, in the event you measure in a shaded space on a scorching day, the shaft will probably be reasonably longer than in the event you measured it within the direct solar.

Humidity and Different Environmental Prerequisites

Humidity, and different environmental stipulations, equivalent to air force, too can have an effect on the accuracy of the dimension. Top humidity can result in moisture accumulation at the shaft’s floor, affecting the accuracy of your dimension. In a similar fashion, drastic adjustments in air force may cause the shaft to make bigger or contract in sudden techniques. Call to mind it like a balloon in numerous atmospheric pressures; it’s going to inflate or deflate accordingly.

Mitigating Environmental Components

To attenuate the have an effect on of environmental components, apply those pointers:

- Make a selection the appropriate time for dimension: Measure the shaft throughout strong climate stipulations, ideally on an afternoon with reasonable temperature and coffee humidity. Keep away from extraordinarily scorching or chilly days and days with fluctuating humidity ranges.

- Take care of a strong setting: If conceivable, behavior measurements in a managed setting, equivalent to a well-ventilated, climate-controlled space. This may occasionally lend a hand decrease the results of temperature and humidity fluctuations.

- Permit the shaft to acclimatize: In case you are measuring a shaft that has been uncovered to other temperatures, permit it to succeed in room temperature earlier than taking the dimension. This guarantees the shaft is at a constant temperature because the measuring tool.

Human Error Components

Human error is some other the most important issue that may affect the accuracy of your shaft size dimension. This contains misreading the measuring tool, fallacious positioning of the measuring device, and different mistakes in method. Human error may also be extra impactful than environmental components in sure instances. Consider seeking to measure a tiny piece of spaghetti with a ruler – chances are you’ll unintentionally misalign the ruler.

Minimizing Dimension Mistakes

To attenuate human error, adhere to those sensible guidelines:

- Use a competent measuring tool: Put money into a top of the range measuring device that gives actual measurements. A virtual caliper or a micrometer are superb alternatives for correct measurements.

- Be certain right kind positioning: Moderately place the measuring device in opposition to the shaft, making sure that the dimension is taken on the suitable issues, perpendicular to the shaft’s floor.

- Double-check measurements: Double-check your readings to make sure accuracy. If conceivable, have someone else check the dimension to cut back the danger of human error.

- Take care of right kind method: Take your time and apply the right kind procedures for measuring the shaft size. Thoroughness is vital to minimizing human error.

Troubleshooting Commonplace Dimension Problems: How To Measure Shaft Period Outboard Motor

Ever had your outboard motor shaft dimension pass haywire? Do not worry, captain! We’re going to navigate the difficult waters of doable pitfalls and get your measurements again on course. From errant rulers to eccentric engines, we’re going to take on the average issues that may throw off your shaft-length calculations.This phase delves into the average snags encountered throughout outboard motor shaft size measurements, providing transparent explanations of why inaccuracies happen and, crucially, find out how to get to the bottom of them.

Exact measurements are paramount for right kind boat repairs and function.

Commonplace Dimension Mistakes and Their Reasons

Working out why your measurements are off is step one in opposition to solving them. Identical to a grumpy seagull, every so often the issue is not the dimension itself, however the equipment, setting, and even the engine’s idiosyncrasies.

- Erroneous Ruler/Tape Measure: A unethical ruler or a tape measure that stretches or contracts can result in faulty readings. Consider seeking to measure your boat’s size with a rubber band – it is sure to be misguided!

- Flawed Alignment: A misaligned ruler or tape measure, or a tilted shaft, can simply introduce mistakes. Image seeking to measure a crooked fence put up – it may not be correct!

- Environmental Components: Temperature fluctuations can impact the accuracy of measurements, particularly with steel gadgets. Consider seeking to measure a scorching steel pipe – it’s going to make bigger, making the dimension misguided.

- Shaft Put on or Injury: A worn or broken shaft may not come up with a correct dimension. Call to mind seeking to measure the size of a damaged pencil – the result’s incorrect!

- Parallax Error: Taking a look on the ruler from an perspective can introduce a parallax error, making a false studying. It is like attempting to pass judgement on the space of a boat from the shore via squinting – it isn’t actual!

Resolving Dimension Inaccuracies

If you determine the supply of the mistake, you’ll be able to follow the suitable answer. It is like diagnosing a unwell engine – you wish to have the appropriate equipment and information to mend it.

- Correct Ruler/Tape Measure: Be certain your ruler or tape measure is immediately and freed from kinks or bends. Use a strong, calibrated ruler for actual readings. That is like the usage of a top of the range measuring tape to make sure correct building.

- Right kind Alignment: Position the ruler or tape measure perpendicular to the shaft. Use a degree to ensure correct alignment, particularly for angled shafts. That is like the usage of a wood worker’s point to make sure an ideal immediately line.

- Controlling Environmental Components: Measure the shaft in a strong setting, loose from excessive temperatures. Attempt to take your measurements in a temperature-controlled house, if conceivable. That is like retaining a lab setting strong to make sure actual clinical measurements.

- Investigate cross-check Shaft Situation: Visually check out the shaft for any indicators of damage or injury. If vital, change the shaft to make sure correct dimension. That is like checking your tires for put on and tear earlier than riding – it guarantees a clean trip.

- Fending off Parallax Error: Take care of a constant eye-level place whilst taking the dimension. Place your self without delay over the shaft and ruler to keep away from any parallax error. That is like taking an image – you wish to have to be in the appropriate place to seize a transparent symbol.

Troubleshooting Desk

| Downside | Purpose | Answer |

|---|---|---|

| Erroneous studying | Bent or stretched tape measure | Use a brand new, calibrated ruler or tape measure. |

| Dimension discrepancy | Misaligned ruler/tape measure | Be certain the ruler/tape measure is perpendicular to the shaft. Use a degree. |

| Various effects | Environmental components (temperature) | Measure in a strong setting. |

| Flawed shaft size | Shaft injury/put on | Investigate cross-check the shaft for injury. If broken, change. |

| Erroneous dimension | Parallax error | Place your self without delay over the shaft and ruler. |

Shaft Period Chart and Specs

Ever really feel like your outboard motor’s shaft is a secret code, most effective decipherable via marine engineers? Concern no longer, intrepid angler! This phase unlocks the mysteries of shaft size, revealing the essential specs hidden inside the depths of your outboard motor’s knowledge sheet. Working out those measurements is the most important for right kind boat compatibility and total efficiency.This phase delves into the interesting global of shaft size charts, offering a complete information to decoding the specifications for more than a few outboard motor fashions.

We’re going to discover how those charts are arranged, what data they include, and find out how to use this data to make sure your boat and engine are an ideal fit. Get ready to transform a shaft-length savvy celebrity!

Outboard Motor Shaft Period Specs

Understanding your outboard motor’s shaft size is like having a secret weapon. It guarantees right kind fitment together with your boat, impacting the entirety from gasoline potency to total efficiency. A accurately matched shaft size avoids doable issues, together with untimely put on and tear, and doable engine injury.

| Outboard Motor Type | Producer | Shaft Period (inches) | Symbol Description |

|---|---|---|---|

| Yamaha F150 | Yamaha | 22 | A swish, silver Yamaha F150 outboard motor is depicted, that includes a prominently displayed shaft this is 22 inches lengthy. |

| Honda BF90 | Honda | 20 | A strong, darkish grey Honda BF90 outboard motor, appearing its shaft extending 20 inches from the decrease unit. |

| Mercury 115 | Mercury | 21 | A colourful blue Mercury 115 outboard motor is proven, with its shaft measuring 21 inches in size. |

| Suzuki DF100 | Suzuki | 19 | A contemporary, pink Suzuki DF100 outboard motor, highlighting a 19-inch shaft size. |

Deciphering the Shaft Period Chart

The desk above supplies a glimpse into the sector of outboard motor shaft lengths. Every row represents a selected outboard motor fashion, along side its corresponding producer and shaft size. The “Symbol Description” column is helping visualize the shaft size inside the context of the motor. Crucially, those values are essential for right kind set up and operation.

Significance of Producer Specs

Referencing the producer’s specs is paramount. They supply actual knowledge, meticulously measured underneath managed stipulations, not like estimates or approximations. The use of those precise specs guarantees the outboard motor and boat are completely matched. This meticulous consideration to element prevents doable problems, maximizing the efficiency and longevity of your funding. A mismatch in shaft size can result in vital efficiency issues, from reduced gasoline potency to serious injury.

Protection Precautions Right through Dimension

Do not be a boating blunderbuss! Right kind protection measures are the most important when dealing with outboard motors and equipment, particularly when taking actual measurements. Somewhat precaution is going a ways in combating doable mishaps and making sure a clean, secure dimension procedure.Cautious attention of protection protocols will turn out to be your dimension consultation from a possible peril to a productive pursuit. Understanding the possible risks and find out how to mitigate them is vital to a secure and a success dimension enterprise.

Dealing with Outboard Motors Safely

Right kind dealing with of outboard motors is paramount to forestall damage. At all times be certain that the motor is securely supported, preferably on a strong stand or workbench. By no means try to raise or transfer a heavy motor on your own. If help is wanted, enlist lend a hand. Moreover, be certain that the motor’s gasoline machine is tired and the spark plug twine is disconnected to forestall unintended beginning.

This the most important step will get rid of the chance of sudden ignition.

Device Protection Measures

Equipment, like every other tools, want recognize. The use of them improperly can result in accidents. At all times check out equipment for any injury earlier than use. Be certain handles are company and safe to forestall slippage. Make sure that the equipment are suitable for the duty to hand, as the usage of the unsuitable device may also be hazardous.

Additionally, stay your workspace blank and arranged to forestall tripping hazards. A well-maintained workspace minimizes the probabilities of injuries.

Dimension Process Protection Pointers

To attenuate dangers throughout the dimension procedure, adhere to those protection guidelines:

- At all times put on suitable protection equipment, together with protection glasses or goggles to give protection to your eyes from flying particles and paintings gloves to give protection to your fingers from sharp edges or doable cuts. Call to mind it as a safeguard in opposition to sudden mishaps.

- Be certain the world across the dimension website online is apparent of obstructions and doable hazards. Transparent pathways save you undesirable collisions and injuries.

- By no means try to measure whilst running underneath a ship or in confined areas with out right kind make stronger and air flow. At all times prioritize protection in confined areas.

- If running close to water, all the time use warning and take vital precautions to keep away from slips and falls. By no means compromise protection for velocity. Being conscious of your setting is the most important in watery environments.

- When the usage of energy equipment, all the time apply the producer’s directions meticulously. Misusing energy equipment can result in unhealthy eventualities. At all times prioritize the producer’s suggestions.

Doable Hazards and Avoidance Methods

Unexpected risks lurk in any dimension enterprise. Pay attention to those hazards and their mitigation methods.

- Sharp edges and corners: At all times use protecting gloves when dealing with parts with sharp edges or corners to forestall cuts. A reduce can disrupt all of your dimension procedure.

- Falling gadgets: Be certain safe make stronger for the outboard motor and surrounding equipment to forestall any doable falling gadgets. Save you injuries via taking preventative measures.

- Electric hazards: Disconnect {the electrical} machine and make sure right kind grounding earlier than any paintings involving electric parts. Keep away from any possibility related to electric mishaps.

- Chemical hazards: Take into account of any chemical substances provide and take vital precautions, together with right kind air flow and protecting equipment. Care for chemical substances with recognize.

Significance of Protection Tools

Suitable protection equipment is non-negotiable. It serves as a the most important barrier in opposition to doable hazards. Protection glasses and paintings gloves are simply two examples of the protection equipment you wish to have. Dressed in suitable equipment prevents accidents from minor scrapes to extra serious injuries. It is an funding for your protection and well-being.

Dangers of Flawed Device Dealing with

Flawed device dealing with can result in severe penalties. A broken device can malfunction, inflicting damage and even injury to the outboard motor. Misusing equipment can result in unexpected hazards. At all times be certain that the equipment are in just right running order earlier than use.

Ultimate Abstract

In conclusion, mastering the artwork of measuring your outboard motor shaft size empowers you to handle optimum boat efficiency. By way of working out the significance of actual measurements, using the appropriate equipment and techniques, and addressing doable problems, you’ll be able to with a bit of luck navigate the complexities of boat repairs. This information supplies a complete useful resource for your whole shaft dimension wishes, making sure a clean and a success boating revel in.

Q&A

What are the average errors to keep away from when measuring shaft size?

Commonplace errors come with the usage of worn or uncalibrated equipment, neglecting environmental components like temperature, and misinterpreting the producer’s specs. At all times be certain that your equipment are in just right situation and take steps to keep watch over environmental variables to reach correct effects.

How can I inform if the shaft size is right kind for my boat?

Seek the advice of the landlord’s guide or the producer’s specs on your boat and outboard motor. A right kind shaft size guarantees the propeller and motor are accurately aligned with the hull, combating doable problems like cavitation or broken propellers.

What occurs if I take advantage of an fallacious shaft size?

The use of an fallacious shaft size can result in efficiency problems, equivalent to diminished velocity, larger vibration, or propeller injury. It is the most important to get the appropriate size for optimum efficiency and the longevity of your outboard motor and propeller.

What’s the significance of the usage of calibrated measuring equipment?

Calibrated equipment supply correct measurements, that are very important for making sure right kind compatibility between the outboard motor and the boat. The use of equipment that have not been calibrated may just result in misguided measurements, doubtlessly inflicting problems with efficiency and longevity.