How one can set up freeze plugs is a the most important ability for any individual operating with automobiles or water techniques. Freeze plugs save you engine or water machine injury all over freezing temperatures, and working out the set up procedure is very important for keeping up those essential elements. This information delves into the intricacies of freeze plug set up, from figuring out the issue to post-installation exams and preventative upkeep.

This complete information will stroll you in the course of the procedure, protecting the entirety from figuring out the indicators of a failing freeze plug to changing the broken element with precision. It additionally touches on crucial protection precautions and preventative upkeep to stay your machine operating easily and keep away from long term problems.

Creation to Freeze Plugs

The relentless march of wintry weather’s icy grip can wreak havoc on our infrastructure, from the common-or-garden water pipes to the intricate mechanisms inside of our automobiles. Freeze plugs, frequently lost sight of, stand as silent sentinels towards the damaging drive of increasing ice. Those the most important elements are the unsung heroes of chilly climates, safeguarding our techniques from catastrophic injury.Freeze plugs are strategically positioned inside of quite a lot of techniques to forestall catastrophic failure led to by means of freezing temperatures.

They’re designed to resist immense force and act as a very important barrier towards the possibly explosive drive of ice increasing inside of confined areas. Their significance extends past mere comfort, encompassing protection and the preservation of precious apparatus.

Freeze Plug Serve as and Significance

Freeze plugs are designed to forestall water pipes, engine blocks, and different elements from bursting because of the growth of water into ice. They’re small, strategically positioned steel plugs that let water to enlarge inside of a managed method, fighting force from exceeding protected limits. This the most important serve as guarantees the integrity of techniques in frigid environments, holding precious apparatus and minimizing the danger of high-priced maintenance or replacements.

Sorts of Freeze Plugs

Other programs call for other fabrics for freeze plugs. Cast-iron freeze plugs, as an example, are frequently present in older engine blocks, recognized for his or her powerful energy. Aluminum freeze plugs, preferred in more recent designs, are prized for his or her light-weight nature and advanced thermal conductivity. The selection of subject matter immediately affects the plug’s talent to resist various ranges of force and temperature fluctuations.

- Cast-iron freeze plugs are sturdy and proof against excessive temperatures, making them superb for heavy-duty programs, however they may be able to be heavier than different choices.

- Aluminum freeze plugs are lighter and extra environment friendly at accomplishing warmth, however their energy is also compromised in sure excessive prerequisites.

Not unusual Freeze Plug Failure Problems, How one can set up freeze plugs

Freeze plug failure can stand up from quite a lot of assets. Corrosion, a sluggish and insidious enemy, can weaken the steel through the years, resulting in leaks and eventual failure. Bodily injury, from affects or mistaken set up, can compromise the integrity of the plug, making it at risk of leaks. Over the years, fatigue can weaken the steel’s talent to resist force.

Possible Penalties of Freeze Plug Failure

The results of freeze plug failure can vary from inconvenient to catastrophic. Minor leaks can result in water injury and expensive maintenance. Extra critical disasters can lead to entire machine failure, probably detrimental or destroying the apparatus. In automobiles, this can result in engine block injury, requiring in depth and costly maintenance. In water techniques, the outcome can also be flooding, probably inflicting vital injury to assets and developing well being hazards.

Comparability of Freeze Plug Fabrics

| Subject material | Strengths | Weaknesses |

|---|---|---|

| Forged Iron | Prime energy, resistance to corrosion, powerful | Heavy, decrease thermal conductivity |

| Aluminum | Light-weight, excellent thermal conductivity | Decrease energy in comparison to cast-iron, extra liable to corrosion in some environments |

Freeze plug failure is a preventable factor with correct upkeep and alternative.

Figuring out the Drawback: How To Set up Freeze Plugs

A failing freeze plug is a silent threat, a ticking time bomb lurking inside of your cooling machine. Ignoring the delicate indicators can result in catastrophic engine failure, leaving you stranded and dealing with pricey maintenance. Working out the telltale signs and using correct inspection tactics is paramount to warding off this doable crisis. Proactive vigilance is your absolute best protection towards engine-damaging leaks.

Indicators of Freeze Plug Failure

Freeze plug failure isn’t all the time obtrusive, however its presence is continuously signaled by means of delicate but vital signs. Those caution indicators, if left out, can temporarily escalate into a significant mechanical disaster. Diligent statement is essential to fighting pricey and time-consuming maintenance.

- Cooling Gadget Overheating: A continual upward thrust in coolant temperature, frequently accompanied by means of the hissing sound of escaping force, alerts a compromised freeze plug. This can be a transparent indication of a possible leak, requiring quick consideration. A vintage instance is a antique automobile, the place a failing freeze plug frequently manifests as an erratic upward thrust in temperature all over chilly climate operation.

- Coolant Leaks: A telltale signal is the presence of coolant puddles underneath the automobile, specifically within the neighborhood of the engine block. This leak may well be sluggish and nearly imperceptible, but it surely nonetheless represents a vital lack of coolant. This may happen on fashionable automobiles in addition to older ones, highlighting the significance of standard inspection.

- Lack of Coolant: A noticeable aid within the coolant degree within the reservoir is a sturdy indicator of a leak. A sluggish, however constant lower is a vital take-heed call. That is frequently a prelude to a bigger downside if no longer addressed in an instant. A well-maintained automobile must no longer be experiencing a considerable lack of coolant over a brief duration.

- Strange Noises: Pay attention intently. A hissing or effervescent sound, particularly noticeable when the engine is operating, would possibly point out a freeze plug leak. The force buildup is the supply of this strange sound. That is specifically noticeable in engines below rigidity.

Visible Inspection Tactics

An intensive visible inspection is the primary defensive line in figuring out freeze plug injury. Cautious statement can disclose vital defects, making an allowance for well timed intervention.

- Exterior Exam: Check out the engine block meticulously for any indicators of leakage or bulging across the freeze plug places. Search for any proof of coolant stains, specifically within the neighborhood of the engine block. A cautious visible inspection is frequently step one in figuring out the supply of coolant loss.

- Enlargement Tank Tracking: Frequently take a look at the coolant degree within the growth tank. A constant drop within the coolant degree, coupled with the opposite signs, strongly suggests a leak. Apply the growth tank for any strange bubbles or indicators of force.

- Shut-Up Inspection: Use a magnifying glass or flashlight to inspect the freeze plugs themselves for any indicators of cracks, corrosion, or deformation. A bulging or misshapen freeze plug can sign a possible leak level. Sparsely read about the skin of the freeze plug for visual indicators of wear.

Drive Trying out for Leaks

A force check can ascertain the presence of a leak, pinpointing the best location of the issue.

- Process: Fill the cooling machine with coolant and follow force. The usage of a force gauge, track the force to make sure it stays inside the applicable vary. Track for any vital drop in force, which is able to sign a leak. A force check is an important software in diagnosing leaks, offering correct and quick effects.

- Leak Detection: Check out the engine block for any spaces the place coolant is leaking. The force check will spotlight the best location of the coolant leak. This system is frequently used at the side of visible inspections to slim down the possible places of leaks.

Gear and Fabrics Required

The center of any a success freeze plug alternative lies within the meticulous variety and exact utility of gear. This meticulous preparation, a symphony of precision, safeguards towards catastrophic failure and guarantees a flawless consequence. Neglecting correct gear can result in irreversible injury, highlighting the vital significance of choosing the proper apparatus.The correct gear and fabrics are crucial for a a success freeze plug alternative.

Flawed variety can result in irreversible injury, probably inflicting some distance better issues than the unique leak. This phase meticulously main points the gear and fabrics required, outlining the significance of each and every element for a protected and efficient restore.

Very important Gear for Freeze Plug Substitute

A complete toolkit is paramount for a a success freeze plug alternative. Each and every software performs a particular function, making sure accuracy and potency during the method. This phase supplies an in depth breakdown of the specified gear, making sure a whole working out in their respective purposes.

- Socket Wrenches and Sockets: Very important for loosening and tightening the bolts and nuts securing the freeze plugs. Other sizes of sockets are required to deal with quite a lot of bolt configurations, and a suite of adjustable wrenches is important for eventualities the place a socket would possibly not have compatibility.

- Have an effect on Wrenches: For terribly tight fasteners, an have an effect on wrench dramatically reduces the hassle required, considerably expanding the potency and protection of the method. Those gear are the most important for cussed bolts and nuts, fighting doable injury to the engine or different elements.

- Torque Wrenches: Vital for attaining the best torque specs at the fasteners. Unsuitable torque can result in leaks or untimely failure, emphasizing the desire for exact torque utility. Those are essential for making sure the integrity of the restore.

- Drain Pans and Catch Trays: An important for gathering the coolant and different fluids all over the elimination and alternative procedure. Those save you spills and make sure a blank paintings surroundings. Right kind containment is very important for protection and environmental coverage.

- Gasket Removing Software: Facilitates the elimination of previous freeze plugs and their related gaskets. Those gear are in particular designed for efficient and protected elimination, fighting injury to the engine or surrounding elements.

- Pry Bars (for sure programs): Helpful for getting rid of cussed freeze plugs or elements obstructing get right of entry to. Pry bars should be used with excessive warning to keep away from detrimental the engine block or different surrounding elements.

Protection Precautions

Protection should be paramount all over any automobile restore. Following those tips guarantees a safe and regulated surroundings.

- Put on suitable protection equipment: Protecting eyewear, gloves, and durable sneakers are crucial for fighting accidents. This safeguards towards doable hazards all over the method.

- Paintings in a well-ventilated house: Coolant and different fluids can also be hazardous. Ok air flow minimizes publicity to destructive fumes and gases.

- Disconnect the battery: Save you unintentional electric shocks by means of disconnecting the automobile’s battery prior to beginning any restore. This precaution is the most important for private protection.

- Use correct lifting tactics: Keep away from straining your self by means of the use of correct lifting tactics when dealing with heavy elements or gear. This prevents accidents all over the restore procedure.

- Apply producer’s directions: Seek the advice of the automobile’s proprietor’s guide for particular tips and procedures, making sure a protected and correct restore.

Fabrics Required

The next fabrics are crucial for an entire freeze plug alternative. Each and every element performs a the most important function within the integrity and longevity of the restore.

| Subject material | Description | Specifics |

|---|---|---|

| Freeze Plugs | Substitute freeze plugs | Make a choice the proper freeze plug sort for the particular engine utility. Seek the advice of the automobile’s restore guide for the suitable freeze plug specs. |

| Coolant | Best-quality coolant | Use the proper form of coolant specified within the automobile’s proprietor’s guide. |

| Gaskets | New gaskets | Fit the gaskets to the freeze plugs for a correct seal. The usage of unsuitable gaskets can result in leaks. |

| Sealant (Not obligatory) | Prime-temperature sealant | For additonal coverage, use a high-temperature sealant across the freeze plugs. This reinforces the seal and additional prevents leaks. |

Making ready the Automobile/Gadget

The chilling grip of wintry weather, or the relentless warmth of summer season, can inflict untold injury upon your automobile’s essential coolant machine. A compromised freeze plug, a silent sentinel of the engine’s middle, can result in catastrophic failure if left unaddressed. This meticulous procedure calls for an actual and calculated means, making sure the protection of the machine and the integrity of the restore.

Draining the Coolant Gadget

The coolant machine, a fancy community of passages and chambers, should be meticulously tired to facilitate protected get right of entry to to the freeze plug. Flawed draining can result in coolant spills, contaminating the surroundings and probably inflicting injury to surrounding elements. This meticulous step is paramount to making sure a a success restore.

- Find the coolant drain plug, generally positioned on the lowest level of the machine. Seek the advice of your automobile’s proprietor’s guide for exact location and continue with excessive warning.

- Place an acceptable container underneath the drain plug to gather the draining coolant. Ensure that the container is big sufficient to deal with all of the quantity and is correctly secured to forestall spillage.

- Sparsely open the drain plug, permitting the coolant to waft into the container. Track the draining procedure to forestall unexpected surges or sudden waft charges.

- As soon as the coolant has utterly tired, shut the drain plug securely. A correctly tightened plug prevents leaks and guarantees the protection of the machine.

Significance of Right kind Coolant Gadget Draining

Thorough coolant machine draining isn’t simply a procedural step; it is a vital protection measure. A in part tired machine can result in inconsistent force, probably detrimental the engine all over the freeze plug alternative procedure. This cautious step minimizes the danger of sudden coolant leakage and lets in for a blank operating surroundings.

Taking out the Affected Section

The affected freeze plug should be moderately got rid of to get right of entry to the broken house. This procedure calls for precision and adherence to protection precautions. Flawed elimination can injury surrounding elements, necessitating additional maintenance.

- Determine the precise location of the freeze plug. Refer in your automobile’s restore guide for exact diagrams and procedures.

- The usage of suitable gear, moderately loosen and take away any fasteners or clips securing the affected section to the coolant machine.

- Disconnect any hoses or connections hooked up to the freeze plug. Ensure that correct id of those elements to keep away from detrimental different portions.

- Sparsely extract the freeze plug, making sure you have got a technique for holding any residual coolant or particles.

Setting apart the Freeze Plug Space

Isolation of the freeze plug house is the most important to fighting additional coolant leaks and contamination. This step establishes a managed operating zone, making an allowance for environment friendly and exact alternative of the freeze plug.

- Determine any doable coolant pathways within the quick neighborhood of the freeze plug. This working out is essential for fighting contamination.

- Make use of suitable seals or limitations to include any residual coolant. This measure guarantees a blank and regulated paintings surroundings.

- Use absorbent fabrics, like rags or towels, to soak up any last coolant or moisture. This proactive measure safeguards the operating house.

Changing the Freeze Plug

The center of your cooling machine, the freeze plug, stands sentinel towards the relentless attack of frigid temperatures. A compromised freeze plug spells crisis, a possible for catastrophic engine failure. This phase main points the meticulous means of changing a freeze plug, a process not easy precision and working out of the intricacies of engine mechanics.

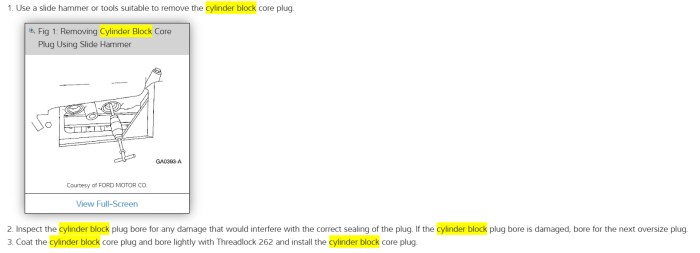

Taking out the Outdated Freeze Plug

The elimination of the broken freeze plug is a vital first step. Flawed elimination can result in additional injury. Care should be taken to keep away from detrimental the encircling engine block. This procedure frequently comes to specialised gear and meticulous consideration to element.

- Find the freeze plug’s place at the engine block. Seek the advice of the automobile’s restore guide for exact id. Unsuitable location can lead to pointless headaches.

- Make use of a freeze plug remover software, designed in particular for this goal. Ensure that the software’s correct have compatibility to forestall slippage and doable injury.

- Practice penetrating oil to the freeze plug for prolonged classes. This aids in loosening the plug and lowering the danger of breakage all over elimination.

- Gently faucet the freeze plug remover software with a hammer, making sure managed moves. Over the top drive can injury the encircling steel.

- As soon as the plug is loosened, moderately take away the software and the freeze plug. Assess the plug for injury. A broken plug might point out underlying issues.

Putting in the New Freeze Plug

The set up of the brand new freeze plug is similarly vital. Right kind set up promises lasting coverage towards freezing temperatures. Care should be taken to make sure a safe seal.

- Ensure that the brand new freeze plug is the proper measurement and subject matter for the appliance. The usage of the unsuitable plug can lead to a compromised seal.

- Completely blank the mating floor at the engine block to get rid of any particles or corrosion. A blank floor guarantees a correct seal.

- Practice an acceptable sealant, comparable to engine sealant, to the skin of the brand new freeze plug. This creates a powerful seal.

- Place the brand new freeze plug exactly into its designated location. Ensure that the plug aligns with the encircling gasket. Flawed alignment can result in leaks.

- Safe the freeze plug the use of an acceptable set up software or an actual way of tapping with a hammer. Ensure that the plug is totally seated and flush with the engine block.

Evaluating Set up Strategies

Quite a lot of strategies exist for putting in freeze plugs. Each and every way carries doable benefits and drawbacks.

- Guide Tapping: A standard way, this comes to the use of a hammer and an acceptable software to faucet the freeze plug into position. It may be efficient however calls for precision to keep away from injury.

- Hydraulic Urgent: This technique makes use of hydraulic force to exactly seat the freeze plug, minimizing the danger of wear. It frequently calls for specialised apparatus and is also extra pricey.

- Particular Gear: Particular freeze plug set up gear might be offering exact positioning and diminished chance of wear. Those gear frequently require familiarity with their particular operation.

Step-by-Step Freeze Plug Substitute Process

| Step | Motion | Necessary Issues |

|---|---|---|

| 1 | Find and determine the freeze plug. | Seek the advice of the automobile’s restore guide. |

| 2 | Practice penetrating oil to the freeze plug. | Permit considerable time for the oil to penetrate. |

| 3 | Use a freeze plug remover to scrupulously take away the previous freeze plug. | Keep away from over the top drive. |

| 4 | Blank the mating floor at the engine block. | Take away any particles or corrosion. |

| 5 | Practice sealant to the brand new freeze plug. | Use an acceptable engine sealant. |

| 6 | Set up the brand new freeze plug and safe it. | Ensure that correct alignment and seating. |

| 7 | Completely take a look at for leaks. | Leaks point out mistaken set up. |

Publish-Set up Exams

The meticulous set up of a freeze plug isn’t entire till rigorous post-installation exams are carried out. Those exams make sure that the integrity of the coolant machine, fighting catastrophic disasters and making sure optimum engine efficiency. A vigilant means is paramount, as a unmarried lost sight of element can result in vital repercussions.Thorough post-installation exams are the most important to ensure the machine’s readiness for operation and long-term reliability.

Those steps will information you via a complete verification procedure, from force trying out to leak detection and coolant fill up.

Coolant Gadget Drive Trying out

Right kind force trying out verifies the seal integrity of the newly put in freeze plug and the entire energy of the coolant machine. A erroneous seal can result in catastrophic force build-up, probably detrimental the engine block. This process is very important for making sure the machine’s readiness to resist operational pressures.

- Start up the force check with the engine chilly and the coolant machine tired of air. Ensure that the machine is depressurized prior to beginning the check to forestall force surges.

- Make use of a force gauge to observe force inside the machine as specified within the automobile’s restore guide. This guarantees correct readings and forestalls doable machine injury.

- Apply the force gauge’s readings during the check period. Fluctuations or fast force drops may just point out a leak or a erroneous seal. This necessitates a cautious exam of the coolant machine.

- Handle the force inside the really helpful working parameters to forestall any doable disasters. The force must stay constant, demonstrating the machine’s talent to resist operational rigidity.

- After the force check, moderately unlock the force to keep away from doable harm and coolant spillage. A managed unlock prevents out of control force unlock.

Leak Detection

A diligent leak take a look at is paramount to making sure the machine’s long-term efficiency and longevity. Ignoring doable leaks can result in considerable coolant loss, inflicting engine overheating and probably critical injury.

- Visually check out all of the coolant machine, together with hoses, connections, and the freeze plug house, for any indicators of leaks. Pay shut consideration to spaces the place coolant traces connect with the engine block. This detailed inspection guarantees no delicate leak is ignored.

- Use a leak detection resolution (comparable to a dye or a unique liquid) to pinpoint hidden leaks that is probably not visual. This resolution aids in figuring out delicate leaks that would possibly in a different way pass not noted. A dye is a useful assist on this procedure.

- Apply the machine for any indicators of wetness, discoloration, or pooling fluid. A scientific exam of all doable leak issues is important to forestall catastrophic disasters.

- Completely take a look at the freeze plug house for any indicators of leakage across the put in plug. This guarantees the seal is undamaged and fighting coolant loss. A cautious exam of the set up website is important.

Coolant Gadget Replenish

As it should be refilling the coolant machine is the most important to make sure optimum engine efficiency and save you overheating. The usage of the unsuitable coolant sort may cause severe injury and compromise the engine’s lifespan.

- Ensure that the engine is cool prior to dealing with any coolant or acting any procedures. Prioritizing protection is very important when operating with sizzling elements.

- Discuss with the automobile’s proprietor’s guide for the suitable coolant sort and capability. The right kind sort and quantity are essential to the engine’s correct operation.

- Sparsely upload the required coolant to the coolant reservoir or growth tank, tracking the extent to make sure the proper quantity is added. Overfilling may cause problems.

- Get started the engine and let it run for a couple of mins to flow into the coolant in the course of the machine. This guarantees the coolant is correctly dispensed during the machine.

- Take a look at the coolant degree once more after the engine has cooled. Upload extra coolant as had to handle the correct degree.

Thorough Leak Take a look at Publish-Set up

A complete leak take a look at after set up guarantees the long-term reliability of the repaired machine. This vital step prevents doable long term problems, making certain the machine’s protection and potency.

- Park the automobile on a degree floor and make allowance the engine to chill utterly.

- Check out all connections, hoses, and the freeze plug house for any indicators of leaks or fluid buildup.

- Use a flashlight or different illumination to completely check out spaces which might be arduous to look immediately.

- Search for any discoloration or pooling of fluid underneath the automobile or across the engine.

- Repeat the leak take a look at at quite a lot of durations over the following couple of days to come across any creating leaks. Proactive exams make sure that doable problems are addressed temporarily.

Prevention and Upkeep

The chilling grip of wintry weather, the relentless pounding of summer season warmth—those environmental extremes can relentlessly attack your automobile’s essential coolant machine. Failing to proactively handle this vital machine can result in catastrophic engine failure, leaving you stranded and dealing with pricey maintenance. This phase main points the most important preventative measures to safeguard your engine from the perils of freeze-plug failure and make sure years of trouble-free operation.Working out the delicate stresses exerted in your engine’s core elements is paramount.

A correctly maintained coolant machine is the engine’s defend towards the corrosive results of time and temperature fluctuations. Ignoring those precautions can lead to untimely put on and tear, necessitating pricey replacements and probably catastrophic injury.

Preventative Measures to Keep away from Freeze Plug Failure

Common vigilance and proactive upkeep are the cornerstones of stopping freeze plug failure. Keeping up the correct coolant ranges and sort, at the side of diligent tracking of the coolant machine, are vital steps on this undertaking.

- Coolant Kind Variety: Using the proper coolant sort in your particular utility is paramount. Seek the advice of your automobile’s proprietor’s guide for the really helpful coolant sort and be sure to are the use of a high quality product that conforms to the criteria Artikeld within the guide. The usage of the unsuitable form of coolant can considerably scale back its effectiveness in fighting corrosion and injury, resulting in untimely freeze plug failure.

- Right kind Coolant Ranges: Keeping up the proper coolant degree is very important. Inadequate coolant leaves essential engine elements at risk of overheating. A visually transparent coolant reservoir is your information to the proper degree. Overfilling too can result in severe issues, together with coolant leaks.

- Common Gadget Exams: Habits regimen visible inspections of the coolant machine. Pay explicit consideration to hoses, clamps, and connections. Early detection of leaks, corrosion, or different anomalies can prevent catastrophic disasters. A meticulous inspection can assist catch delicate leaks prior to they escalate into primary issues.

- Corrosion Coverage: Make the most of corrosion inhibitors within the coolant machine to give protection to elements from oxidation and rot. Corrosion can critically weaken freeze plugs, making them liable to cracking and leakage below rigidity.

Significance of Common Coolant Gadget Upkeep

A meticulously maintained coolant machine is similar to a well-oiled device. Common exams and well timed maintenance are the most important to fighting pricey breakdowns and making sure optimum engine efficiency.

- Proactive Leak Detection: A well-maintained coolant machine is much less liable to leaks. Addressing any coolant loss promptly is essential. Leaks, regardless of how small, can result in overheating, freeze plug injury, and catastrophic engine failure.

- Common Flush and Fill: Common flushing of the coolant machine is essential for getting rid of contaminants and corrosion byproducts that may weaken the machine and motive untimely failure. Use of a high quality coolant flush and fill resolution, as directed by means of your proprietor’s guide, is very important.

- Tracking Temperature: Frequently tracking the engine temperature is the most important for detecting any overheating problems. An engine working out of doors its optimum temperature vary is below super rigidity, probably resulting in freeze plug failure.

Right kind Coolant Kind for Other Packages

The right kind coolant sort in your automobile’s utility is the most important. The usage of the unsuitable coolant can critically injury your engine.

| Utility | Really helpful Coolant Kind |

|---|---|

| Automobiles with Aluminum Radiators | Coolants in particular formulated for aluminum radiators to forestall corrosion. |

| Automobiles with Iron or Metal Radiators | Coolants formulated for iron or metal radiators, which would possibly not include sure corrosion inhibitors present in aluminum-specific coolants. |

| Prime-Efficiency Automobiles | Coolants designed for upper temperatures and pressures, making sure top efficiency. |

Keeping up the Coolant Gadget

Keeping up a pristine coolant machine comes to meticulous consideration to element and adherence to producer specs.

- Right kind Flushing Tactics: Make the most of specialised flushing answers and procedures to make sure entire elimination of contaminants and particles. Apply the producer’s directions for optimum effects.

- The usage of Prime-High quality Coolant: Make use of high quality coolant to reinforce the machine’s longevity and save you corrosion. Seek the advice of your proprietor’s guide for particular suggestions.

- Adhering to Producer Specs: At all times adhere to the producer’s suggestions for coolant sort, upkeep durations, and different pertinent main points.

Common Coolant Gadget Upkeep Tick list

Common coolant machine upkeep is the most important for optimum engine efficiency and longevity.

- Visible Inspection: Check out hoses, clamps, and connections for leaks or injury.

- Coolant Degree Take a look at: Test coolant degree within the reservoir.

- Coolant Flush: Agenda coolant flushes as in keeping with producer suggestions.

- Temperature Tracking: Track engine temperature all over operation.

- Coolant Kind Verification: Ascertain coolant sort is suitable in your automobile.

- Skilled Inspection: Search skilled inspection if any anomalies are detected.

Troubleshooting Not unusual Problems

The subtle dance of changing freeze plugs can, now and then, result in unexpected headaches. A reputedly simple process can turn into right into a irritating struggle towards leaks and malfunctions. Working out the possible pitfalls and their treatments is paramount to a a success and lasting restore. Right kind diagnostics and decisive motion are key to navigating those demanding situations and restoring the integrity of your cooling machine.

Figuring out Leaks After Set up

A continual leak after putting in new freeze plugs calls for meticulous investigation. Visible inspection, coupled with force trying out, is the most important. A leak might manifest as a sluggish drip, a gentle flow, or a noticeable rainy spot. Sparsely read about the world surrounding the freeze plug set up website, paying shut consideration to any indicators of moisture. A soapy water resolution can assist pinpoint the best leak location.

This technique comes to making use of the answer across the suspected house, permitting the bubbles to suggest the leak’s beginning.

Flawed Set up Problems

Mistakes all over set up can manifest as leaks, or, in excessive circumstances, catastrophic disasters. Ensure that the freeze plug is correctly seated within the cylinder’s bore. Misalignment, mistaken torque, or the use of the unsuitable measurement plug can result in vital issues. A slight misalignment can create a microscopic hole, which, below force, might transform a leak level. Test the plug’s correct seating with a feeler gauge to make sure a comfortable have compatibility.

Desk of Not unusual Issues and Answers

| Drawback | Answer |

|---|---|

| Leak at Freeze Plug Set up Web page | Re-torque the plug to the producer’s specs. Check out for injury or misalignment. If important, re-install the plug, making sure correct seating. Use a leak detection resolution for precision leak id. |

| Leak at a Other Engine Part | If the leak is indirectly on the freeze plug, take a look at the coolant hoses, water pump, or radiator for leaks. A erroneous gasket, worn seals, or a broken element might be the supply. Changing the erroneous element is also required. |

| Freeze Plug Will No longer Seat Correctly | Ensure that the freeze plug is the proper measurement and subject matter for the engine’s particular utility. The usage of the unsuitable measurement or subject matter can result in problems in seating and motive leaks. Make use of the proper set up gear and strategies. Check out the cylinder bore for imperfections or injury. A broken bore would require restore prior to putting in the freeze plug. |

| Over the top Leakage After Set up | A vital leak necessitates quick consideration. The cooling machine must be depressurized and checked for any further leaks. Examine the opportunity of a coolant passage obstruction. Seek the advice of a professional mechanic if the issue persists. |

Solving Leaks After Set up

Solving leaks after set up calls for a methodical means. First, determine the precise location of the leak the use of soapy water. As soon as positioned, the leak must be addressed immediately. If the leak is minor and localized to the freeze plug, moderately re-torque the plug to the proper specs. If the leak persists or is in depth, the freeze plug might want to get replaced, at the side of correct evaluation of the encircling elements.

Seek the advice of a restore guide for particular torque specs and procedures. If the problem persists, imagine looking for skilled help.

Ultimate Conclusion

In conclusion, changing freeze plugs is a multifaceted activity not easy cautious consideration to element. By means of following the stairs Artikeld on this information, you’ll successfully set up new freeze plugs, making sure the integrity and longevity of your machine. Have in mind, correct upkeep and prevention are key to keeping off pricey maintenance down the street.

FAQ Information

What are the typical signs of a failing freeze plug?

Not unusual signs come with coolant leaks, strange noises from the engine, and a drop in coolant ranges. A visible inspection is the most important to identify any visual injury.

What gear are crucial for freeze plug alternative?

A complete software package is important, together with wrenches, sockets, pliers, a drain pan, and protection glasses. The particular gear relies on the automobile’s make and style and the kind of freeze plug.

How do I correctly drain the coolant machine prior to changing a freeze plug?

Seek the advice of your automobile’s proprietor’s guide for particular directions, however normally, find the drain plug, open it, and make allowance the coolant to empty utterly into an acceptable container. Ensure that the world is well-ventilated.

What are the possible penalties of a freeze plug failure?

Freeze plug failure can result in coolant leaks, engine overheating, and expensive maintenance. In critical circumstances, it may injury the engine or different vital elements.