Tips on how to export cadwox part to soild – Tips on how to export CADWorx components to SolidWorks? This information supplies a complete walkthrough, from figuring out the tool variations to sensible examples. Be informed the step by step procedure for seamlessly shifting CADWorx information to SolidWorks, making sure compatibility and accuracy.

This in-depth instructional simplifies the often-complex job of exporting CADWorx components. We’re going to duvet quite a lot of document codecs, export choices, and troubleshooting commonplace problems. From elementary exports to complicated tactics, you can acquire a radical figuring out of all the procedure.

Creation to CADWorx and SolidWorks: How To Export Cadwox Part To Soild

CADWorx and SolidWorks are robust design equipment used widely in engineering, in particular for piping and 3-d modeling, respectively. Working out their person strengths and weaknesses is a very powerful for deciding on the precise tool for a given undertaking. This evaluation will discover the functionalities of every, highlighting their respective features and suitability for various engineering duties.

CADWorx Evaluation

CADWorx is a specialised design tool essentially all for piping and pipeline methods. It excels in growing detailed 2D drawings and 3-d fashions of advanced piping networks. Its core functionalities come with growing isometric drawings, producing invoice of fabrics, and acting tension research for piping methods. CADWorx is famend for its potency in dealing with the intricacies of piping design, from preliminary conceptualization to ultimate documentation.

It is a essential software for engineers running on tasks requiring exact and complete piping layouts.

SolidWorks Evaluation

SolidWorks is a complete 3-d modeling tool in a position to dealing with quite a lot of engineering design duties. Past piping, it lets in for the advent of detailed 3-d fashions of mechanical portions, assemblies, and sophisticated buildings. Its options come with refined 3-d modeling equipment, simulation features, and strong drafting equipment. SolidWorks is a flexible software that facilitates the design, research, and visualization of a limiteless array of goods and parts.

Comparability of CADWorx and SolidWorks

This desk Artikels the strengths and weaknesses of CADWorx and SolidWorks for quite a lot of engineering duties:

| Engineering Job | CADWorx | SolidWorks |

|---|---|---|

| Piping Design | Superb, extremely specialised equipment for detailed piping layouts. | Good enough for easy piping methods, however lacks the specialization of CADWorx. |

| 3-d Modeling of Mechanical Portions | Restricted features for common 3-d modeling past piping. | Superb features for complete 3-d modeling of mechanical portions and assemblies. |

| Detailed Drafting | Robust emphasis on 2D drafting for piping documentation. | Excellent drafting features for 2D and 3-d perspectives, flexible for various wishes. |

| Simulation and Research | Fundamental simulation features essentially for piping tension research. | Intensive simulation features for quite a lot of mechanical methods, together with structural research. |

| Invoice of Fabrics Technology | Powerful equipment for producing complete invoice of fabrics particular to piping. | Equipment for invoice of fabrics, however now not as all for piping-specific wishes as CADWorx. |

A key takeaway is that CADWorx is most suitable for piping-intensive tasks, whilst SolidWorks shines when complete 3-d modeling and research are paramount. Choosing the proper tool hinges at the particular necessities of the undertaking.

Working out CADWorx Part Export

Exporting components from CADWorx to SolidWorks is a simple procedure, a very powerful for seamless integration of piping and instrumentation diagrams (P&IDs) into 3-d fashions. A transparent figuring out of the exportable components, supported document codecs, and a very powerful export parameters is very important for a easy workflow. This guarantees correct illustration and environment friendly usage of the knowledge inside SolidWorks.CADWorx gives a complete vary of options for growing piping and instrumentation diagrams.

Working out the particular components that may be exported is vital to maximizing the usage of the knowledge throughout the goal tool. This comes to understanding what parts of the CADWorx style are to be had for switch to SolidWorks for additional processing and design.

Exportable CADWorx Components

CADWorx lets in the export of quite a lot of components a very powerful for growing complete 3-d fashions. Those come with pipes, fittings, valves, flanges, tools, helps, and different similar parts. Right kind identity of those components inside CADWorx is essential for correct export and seamless integration into SolidWorks. The collection of components to export immediately affects the ensuing 3-d style.

Supported Report Codecs

CADWorx supplies flexibility within the document codecs used for exporting components. The supported codecs facilitate quite a lot of integration wishes and make allowance for optimum information switch. Not unusual codecs come with IGES, STEP, and local CADWorx codecs. Settling on the precise structure is a very powerful for compatibility with SolidWorks and different tool methods.

Export Parameters

A number of parameters affect the standard and completeness of the exported information. Cautious attention of those parameters is essential for making sure a easy export procedure and a correct illustration of the weather in SolidWorks. Parameters like part variety, coordinate methods, and export settings immediately affect the end result. Making sure the right kind coordinate machine is used, for instance, avoids possible misalignment within the 3-d style.

Not unusual Export Choices

The next desk illustrates commonplace export choices inside CADWorx, together with the collection of document codecs. Opting for the right kind export choices is important for attaining desired results.

| Export Possibility | Report Structure | Description |

|---|---|---|

| Pipes | IGES | Exports pipe segments and similar data in a regular structure. |

| Fittings | STEP | Exports becoming main points and connections for 3-d style advent. |

| Valves | Local CADWorx | Preserves the unique valve data for simple referencing. |

| Flanges | IGES/STEP | Exports flange dimensions and configurations for correct modeling. |

| Tools | STEP | Exports device main points for whole illustration within the 3-d style. |

Exporting Procedures

Exporting CADWorx components to SolidWorks is a simple procedure that empowers seamless information switch. This process guarantees the integrity of your designs and facilitates collaboration throughout other platforms. Working out the stairs concerned, from deciding on the required part to configuring the export settings, is a very powerful for environment friendly workflow.Exporting CADWorx components to SolidWorks is facilitated by means of a chain of exact steps.

Each and every step is designed to streamline the method and make sure that the knowledge is appropriately interpreted and transferred, keeping up the integrity of the design. Cautious consideration to those steps promises that the exported information appropriately displays the unique CADWorx part.

Settling on the Desired Part for Export

To start out the export procedure, exactly figuring out the CADWorx part you plan to switch is very important. Navigation throughout the CADWorx surroundings is vital to this option. A transparent figuring out of the part’s location and homes throughout the CADWorx style is paramount. This guarantees that the supposed part is selected and that no unintentional parts are incorporated within the export.

Fallacious variety can result in mistakes within the SolidWorks style.

Essential Settings and Configurations

Configuring the export settings is a very powerful for a a hit switch. Right kind configuration guarantees that the exported information appropriately displays the supposed CADWorx part. This contains parameters such because the structure, gadgets, and any particular choices related to the export procedure. Fallacious settings can result in information loss or misinterpretations within the SolidWorks style. Those settings must be meticulously reviewed ahead of starting up the export.

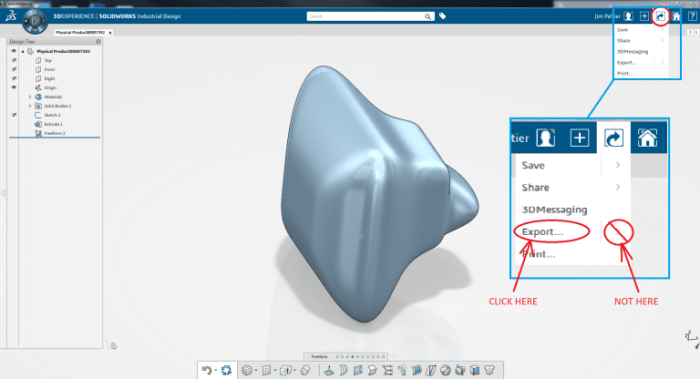

Export Choices in CADWorx

CADWorx gives quite a lot of export choices, every with a selected affect at the exported information. Those choices permit for personalisation to fulfill particular wishes. Working out those choices is a very powerful for tailoring the export to care for the integrity of the unique CADWorx information. For example, deciding on an in depth export choice will come with extra information issues, whilst a simplified choice will scale back the dimensions of the exported document.

Instance Export Workflow

The standard export workflow comes to a number of key steps, from preliminary variety to ultimate export. The method starts with figuring out the CADWorx part to be exported. Subsequent, evaluate the to be had export choices to make sure that the required information is captured. The settings will have to be configured accurately, taking into consideration the objective SolidWorks style. After all, begin the export procedure, tracking the growth.

Moderately reviewing the exported document in SolidWorks is a a very powerful step to make sure that the knowledge used to be effectively transferred.

Strategies for Information Switch

Choosing the proper manner for shifting your CADWorx part information to SolidWorks is a very powerful for a unbroken workflow. A easy transition guarantees accuracy and minimizes possible mistakes to your designs. Settling on the precise document structure and figuring out possible compatibility problems are key to a a hit information alternate.Efficient information switch between CADWorx and SolidWorks hinges at the compatibility of the selected document structure.

This compatibility promises that the nuances of the CADWorx information are preserved throughout the import procedure. Cautious attention of the export process and possible problems is paramount to a a hit and error-free information migration.

Other Switch Strategies

Quite a lot of strategies facilitate the switch of CADWorx components to SolidWorks. Those strategies come with direct import choices, third-party tool answers, and guide information conversion. Probably the most appropriate manner will depend on the complexity of the knowledge and the particular necessities of the undertaking.

Information Compatibility Issues

Making sure information compatibility between CADWorx and SolidWorks is very important for keeping up design integrity. Discrepancies in document codecs or information buildings can result in inaccuracies, requiring important remodel. Thorough figuring out of the nuances of each methods and the export choices presented by means of CADWorx is a very powerful. It’s a must to examine that the exported information aligns with SolidWorks’ anticipated enter codecs to steer clear of mistakes.

Report Structure Comparability

Other document codecs have various levels of compatibility and information preservation features. Settling on the precise structure is important for a a hit switch. A comparability desk outlining the benefits and downsides of every structure is supplied under.

| Report Structure | Benefits | Disadvantages | Suitability for CADWorx to SolidWorks Switch |

|---|---|---|---|

| IGES (Preliminary Graphics Alternate Specification) | Broadly supported, somewhat easy structure. | Restricted illustration of advanced options, possible lack of information. | Appropriate for elementary shapes however would possibly now not appropriately seize advanced fashions. |

| STEP (Same old for the Alternate of Product style information) | Wealthy information illustration, extra powerful than IGES. | Can also be extra advanced to take care of and probably greater document sizes. | Extra appropriate for shifting intricate main points. |

| Parasolid | Preserves style geometry with prime accuracy. | Restricted enhance in some tool, might require conversion. | Superb choice for protecting advanced fashions if SolidWorks helps it. |

| Local CADWorx Structure | Direct import with probably fewer mistakes. | Calls for particular import options in SolidWorks or probably a conversion software. | Preferrred if SolidWorks helps direct import for the CADWorx document structure. |

Attainable Problems and Answers

Right through the knowledge switch procedure, a number of problems might get up. A radical figuring out of those possible issues is vital to minimizing disruption and making sure a easy procedure.

- Misguided Information Illustration: The exported information would possibly now not appropriately replicate the unique CADWorx design. This may happen because of incompatibility problems or mistakes throughout the export procedure. Check the imported information in opposition to the unique CADWorx style to spot any discrepancies. Be sure that all required information layers and attributes are incorporated within the export settings.

- Report Measurement Problems: Excessively massive document sizes can obstruct the switch procedure. Make use of tactics equivalent to information compression to control document measurement and optimize switch velocity. Take a look at SolidWorks’ import limits and imagine breaking down massive fashions into smaller, manageable portions for import.

- Lacking or Corrupted Information: Information components could be lacking or corrupted throughout the switch procedure. That is particularly related when the usage of third-party tool or much less appropriate document codecs. Moderately read about the imported style for any lacking or corrupted components. Use backup copies of the unique information to revert to if wanted.

- Compatibility Problems: Variations in information buildings and functionalities between CADWorx and SolidWorks can result in compatibility issues. Completely examine the document structure and make sure each methods have compatibility with the selected structure. Check if the vital SolidWorks add-ins or plugins are put in and functioning appropriately.

Troubleshooting Not unusual Problems

Navigating the virtual panorama of CADWorx and SolidWorks can infrequently provide surprising demanding situations. Effectively shifting information between those robust design equipment hinges on meticulous consideration to element and a proactive option to possible pitfalls. This phase delves into commonplace issues encountered throughout the export and import procedure, providing sensible answers and making sure a easy transition to your CAD tasks.Exporting and uploading CAD information, particularly between other platforms, can introduce quite a lot of demanding situations.

Working out those problems and find out how to cope with them will streamline your workflow, reduce mistakes, and save treasured time.

Attainable Mistakes Right through Export

A cautious evaluate of the export settings is a very powerful to steer clear of commonplace mistakes. Misguided settings can result in incomplete or corrupted information, rendering the import procedure useless. Reviewing the selected document structure, gadgets, and export choices guarantees the knowledge appropriately displays the supposed design. Misconfigured export parameters can lead to misplaced data, requiring a re-export with the right kind settings.

Problems Right through Import into SolidWorks

Uploading CADWorx components into SolidWorks would possibly come across incompatibility problems. Discrepancies in document codecs or information buildings can create hindrances. A radical figuring out of SolidWorks’ import features and the particular information structure of the CADWorx part is very important for seamless integration.

Resolving Information Structure and Unit Conflicts

Information structure and unit discrepancies are common demanding situations. CADWorx and SolidWorks would possibly make use of other inner representations of dimensions, gadgets, and attributes. Make sure constant unit methods (e.g., millimeters, inches) throughout each export and import. If discrepancies get up, make the most of SolidWorks’ equipment to regulate gadgets and information codecs as vital to reach compatibility. For instance, if an exported drawing specifies dimensions in inches, however SolidWorks makes use of millimeters, a conversion is wanted ahead of uploading to steer clear of mistakes within the style.

Information Validation After Export and Import

Validating the imported information is very important for high quality keep an eye on. After the import, completely investigate cross-check the imported SolidWorks style to verify that each one components are appropriately positioned, scaled, and orientated. Checking dimensions and attributes in opposition to the unique CADWorx information guarantees accuracy. This step can disclose any discrepancies or mistakes that want additional consideration. This meticulous validation step prevents downstream issues.

Not unusual Mistakes and Troubleshooting Steps

| Error Description | Troubleshooting Steps ||—|—|| Fallacious document structure decided on throughout export | Check the compatibility of the chosen document structure with SolidWorks. Discuss with the CADWorx and SolidWorks documentation for supported codecs. || Lacking or corrupted information after export | Evaluate export settings and make sure all vital information is incorporated. If problems persist, re-export the CADWorx part with corrected settings.

|| Incompatible gadgets between CADWorx and SolidWorks | Moderately read about the gadgets utilized in each tool programs. Make the most of conversion equipment or SolidWorks’ unit settings to align the gadgets for seamless import. || Components now not uploading appropriately or exhibiting in SolidWorks | Take a look at the integrity of the exported document. Be sure that all vital parts and attributes were incorporated.

If mistakes persist, re-export and re-import the document. || Problems with information construction or attributes throughout import | Evaluate the compatibility of knowledge buildings and attributes between the 2 tool programs. If vital, modify settings or use SolidWorks’ information manipulation equipment to unravel any inconsistencies. |

Complex Exporting Tactics

Mastering the export procedure from CADWorx to SolidWorks comes to extra than simply the fundamental steps. Optimizing the export procedure, improving information high quality, and controlling element ranges are a very powerful for a unbroken transition and correct illustration within the goal tool. This phase dives into complicated tactics to make sure a easy and environment friendly workflow.

Optimizing the Export Procedure

Environment friendly export procedures save treasured time and assets. Strategic making plans and leveraging CADWorx’s export options can considerably streamline the method. Cautious attention of document measurement, export settings, and information variety reduces processing time in SolidWorks, taking into consideration faster design iterations.

Bettering Information High quality and Accuracy

Keeping up information integrity throughout the export procedure is paramount. This comes to verifying the accuracy of the exported geometry, making sure that dimensions and tolerances are preserved, and confirming that each one vital attributes are incorporated. This meticulous manner promises that the CADWorx components appropriately translate into SolidWorks, minimizing mistakes and remodel. By means of checking the accuracy of the exported recordsdata ahead of continuing to the following level, designers can save time and make sure a easy transition.

Controlling the Stage of Element

The complexity of the exported CADWorx components immediately affects the SolidWorks style’s efficiency. CADWorx lets in granular keep an eye on over the extent of element, enabling designers to export most effective the vital data for the present design section. Exporting parts with diminished geometry complexity hurries up SolidWorks’ loading instances and complements the whole design enjoy. For instance, if a selected part isn’t required for a initial research, it may be excluded from the export, thus bettering efficiency with out sacrificing accuracy for the duty to hand.

Exporting Explicit Attributes or Homes, Tips on how to export cadwox part to soild

CADWorx gives the power to selectively export particular attributes and homes of components. This option lets in for exact information switch, enabling the objective utility (SolidWorks) to make use of most effective the desired data, whilst apart from useless information. This centered manner guarantees that the SolidWorks style is light-weight and most effective contains the attributes related to the design job. For instance, exporting most effective the fabric kind and dimensions of a pipe becoming gets rid of extraneous information, which is really helpful for research functions.

Customizing Export Settings for SolidWorks Compatibility

Customizing the export settings is very important for making sure seamless compatibility with SolidWorks. This contains adjusting parameters equivalent to document structure, coordinate methods, and gadgets to align with SolidWorks’ expectancies. Cautious configuration guarantees that the exported information is immediately usable in SolidWorks, minimizing possible mistakes or inconsistencies. A well-configured export procedure interprets immediately to diminished remodel time and larger design potency.

Sensible Examples and Use Instances

Let’s dive into some real-world situations the place exporting CADWorx components to SolidWorks proves extremely treasured. Believe streamlining your design procedure, heading off redundant paintings, and boosting potency—that is precisely what those tactics can succeed in. This phase will discover sensible programs and show the seamless switch of knowledge between those robust design equipment.Exporting CADWorx components to SolidWorks gives an unbelievable pathway to leverage the strengths of each platforms.

CADWorx excels at growing detailed piping and instrumentation diagrams (P&IDs), whilst SolidWorks shines in 3-d modeling and mechanical design. By means of successfully shifting components, we will be able to mix the most efficient of each worlds, growing extra complete and correct designs.

State of affairs: Exporting a Pipe Becoming to SolidWorks

This situation will information you during the means of exporting a pipe becoming from CADWorx and uploading it into SolidWorks. This particular situation demonstrates find out how to care for the best main points of the part throughout the switch procedure.

Steps for Exporting and Uploading a Pipe Becoming:

- Make a selection the Pipe Becoming: In CADWorx, moderately choose the particular pipe becoming you plan to export. Make sure you’ve decided on the right kind part.

- Exporting the Part: Make use of the CADWorx export serve as to SolidWorks. This option is typically readily to be had within the CADWorx tool’s menu machine. Pay shut consideration to the choices throughout export, as those will dictate the overall illustration of the part in SolidWorks. Make sure correct settings are selected to maintain the essential main points, equivalent to dimensions, fabrics, and floor finishes.

- Import into SolidWorks: Open SolidWorks and navigate to the import serve as. Find the exported CADWorx document. Import the document following this system’s usual process. SolidWorks will most likely supply choices to keep an eye on the import procedure. Evaluate the settings moderately to steer clear of surprising transformations or information loss.

- Verification: As soon as the best is imported, moderately read about it in SolidWorks. Double-check the size, the geometry, and the whole illustration to verify that the knowledge switch used to be correct. If vital, use SolidWorks’ equipment to fine-tune the imported becoming. This step is a very powerful to care for the integrity of the design information.

Use Instances in Engineering Design

Exporting CADWorx components to SolidWorks may also be really helpful in a lot of engineering design situations. Those use circumstances show how the mixed energy of those equipment can optimize quite a lot of levels of a undertaking.

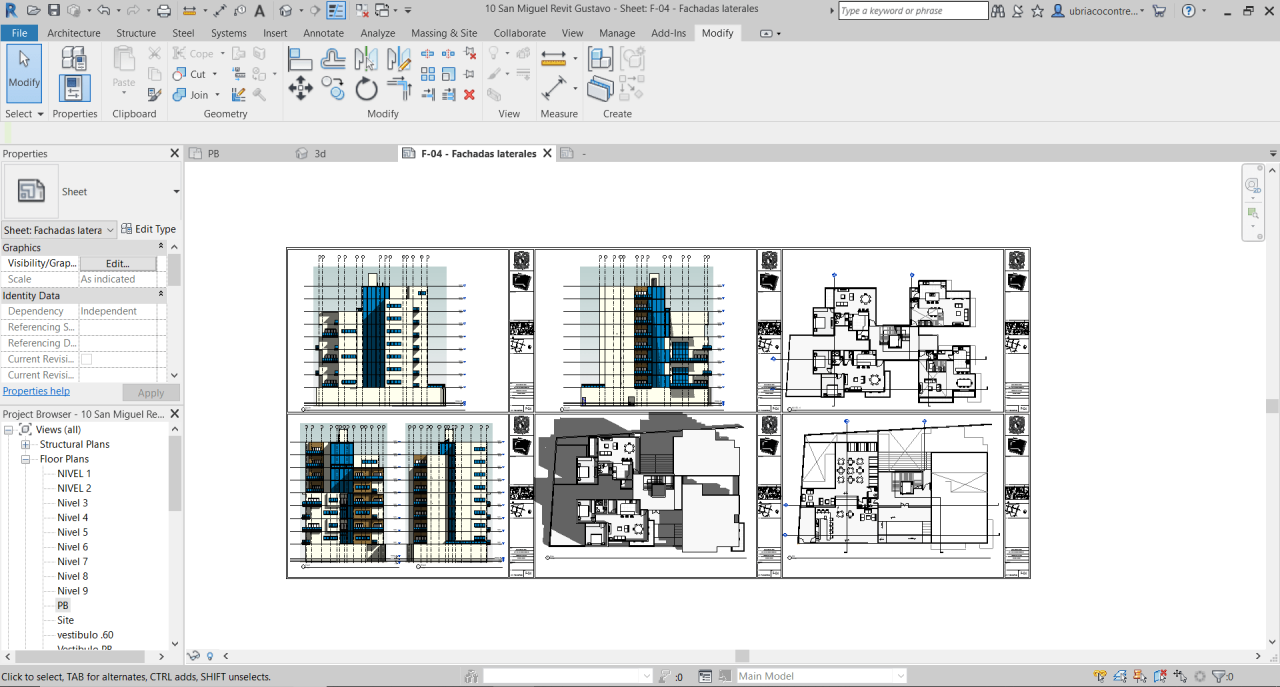

- Detailed 3-d Modeling: CADWorx usally supplies a 2D illustration. Exporting permits you to create detailed 3-d fashions in SolidWorks, incorporating the best specs of the CADWorx components. This 3-d illustration facilitates higher visualization, research, and communique of the design.

- Mechanical Design Integration: Exporting components like valves and pumps from CADWorx into SolidWorks can be utilized to style the entire mechanical design, together with the relationship issues and useful sides. This permits for an entire and holistic design research.

- Conflict Detection and Interference Research: By means of integrating CADWorx components into the SolidWorks style, engineers can carry out conflict detection and interference research extra successfully. This is very important to make sure the parts have compatibility in combination appropriately and steer clear of possible problems throughout meeting.

- Production Preparation: The exported 3-d fashions from CADWorx facilitate higher preparation for production processes. The correct dimensions and geometry can be utilized to create correct production drawings and enhance the manufacturing workflow.

Advantages of Exporting and Uploading

The method of exporting CADWorx components to SolidWorks items important benefits within the engineering design procedure. This phase main points the important thing advantages of using this technique.

- Potency and Time Financial savings: By means of streamlining the switch of knowledge between CADWorx and SolidWorks, engineers can considerably scale back design time. This may translate to quicker undertaking of completion and progressed general potency.

- Enhanced Design Accuracy: Actual information switch promises that the design main points from CADWorx are appropriately mirrored within the SolidWorks style. This stage of accuracy is important in heading off pricey mistakes and making sure a prime stage of high quality within the ultimate product.

- Advanced Collaboration: The seamless switch of knowledge allows progressed collaboration between other engineering groups, as they may be able to all get admission to the similar information in a constant structure.

Concluding Remarks

In conclusion, exporting CADWorx components to SolidWorks is a treasured talent for engineers. This information has supplied you with the data and sensible steps to effectively navigate the export procedure, making sure information integrity and potency. By means of figuring out the intricacies of the method, you’ll be able to leverage CADWorx’s features throughout the SolidWorks surroundings for seamless design workflows.

FAQ Evaluation

What document codecs are supported for exporting CADWorx components?

CADWorx helps quite a lot of document codecs for export, together with .dwg, .dxf, and proprietary codecs. The most efficient structure usally will depend on the particular SolidWorks import features.

What are some commonplace mistakes throughout the import procedure into SolidWorks?

Not unusual import mistakes come with incompatible document codecs, lacking information, or problems with gadgets. Cautious information validation and evaluate of export settings can mitigate those issues.

How can I be sure that information compatibility between CADWorx and SolidWorks?

Information compatibility is a very powerful. The use of suitable document codecs, reviewing export settings, and figuring out the constraints of every tool can enhance compatibility.

What are the stairs for deciding on the required part for export in CADWorx?

The choice procedure usually comes to highlighting the part in CADWorx and opting for the export choice. Detailed directions are to be had throughout the CADWorx tool.