How you can disable z give up in marlin? This deep dive into Marlin firmware uncovers the secrets and techniques to disabling your 3-d printer’s Z-stop, a an important protection characteristic that may once in a while be a ache. We’re going to navigate during the complexities of configurations, doable problems, and an important protection concerns, making sure you might be provided to make knowledgeable selections in your 3-d printing adventure.

This information supplies a complete method to disabling the Z-stop, encompassing quite a lot of strategies, troubleshooting steps, and protection precautions. We’re going to equip you with the data and self belief to accomplish this variation safely and successfully.

Working out Z-Prevent in Marlin

Mastering the Z-stop mechanism is an important for making sure the protection and reliability of your 3-d printing procedure. It is a essential part that forestalls harm in your printer and the print itself. Working out its serve as and configuration means that you can fine-tune your 3-d printing surroundings, main to raised high quality prints and an extended lifespan in your device.

Z-Prevent Serve as in Marlin Firmware

The Z-stop in Marlin firmware acts as a security mechanism, fighting the Z-axis from descending too a long way or crashing into the mattress. It is designed to halt the downward motion of the Z-axis when a bodily sensor detects a collision with the Z-stop sensor, fighting doable harm to the nozzle, the mattress, or the printer itself. This proactive protection characteristic is very important for the long-term well being of your 3-d printer.

Position of Z-Prevent in 3-d Printing

The Z-stop performs an important function in keeping up the structural integrity of the 3-d printing procedure. It promises the printer safely reaches the preliminary print place, making sure that the nozzle does no longer strike the print mattress earlier than the print is initiated. This prevents undesirable harm and lets in for actual and regulated print actions. Correctly configured Z-stops are crucial for attaining fine quality prints and heading off expensive upkeep.

Z-Prevent Sensor Operation

A Z-stop sensor usually is composed of a bodily transfer that turns on when the Z-axis encounters a bodily give up. This transfer is electrically hooked up to the keep an eye on device. When the transfer is induced, the device straight away stops the Z-axis from descending additional. The sensor supplies a essential comments loop, making sure the protection and integrity of the print procedure.

Commonplace Causes for Z-Prevent Adjustment or Disablement

A number of components can necessitate changes or disablement of the Z-stop characteristic. Every now and then, the Z-stop sensor is also misaligned, leading to false triggers. A miscalibrated sensor would possibly purpose the printer to prevent hastily, resulting in print disasters or wasted subject matter. On the other hand, if the Z-stop is situated too a long way from the mattress, the printer would possibly no longer locate it all through the preliminary homing procedure.

In some instances, customers might wish to disable the Z-stop to allow printing with customized construct plates that would possibly impede the Z-stop’s trail.

Standard Z-Prevent Configuration Settings in Marlin

Marlin firmware supplies customizable settings for configuring the Z-stop. Those settings incessantly come with parameters for the Z-stop sensor’s pin, activation thresholds, and the behaviour when the sensor is induced. Those settings are essential for actual operation. The particular settings might range somewhat relying at the explicit printer fashion and the Z-stop sensor sort. You must seek the advice of your printer’s documentation for essentially the most correct settings.For instance, a commonplace configuration would possibly contain specifying the virtual enter pin hooked up to the Z-stop sensor and defining the brink at which the sensor triggers the give up sign.

It is an important to grasp and as it should be configure those parameters.

Find out how to Disable Z-Prevent

Disabling the Z-stop to your 3-d printer can be offering larger printing pace and potency, nevertheless it comes with an important dangers. This segment main points quite a lot of easy methods to disable the Z-stop in Marlin, outlining the procedures and highlighting the possible penalties. Working out those implications is paramount for protected and a success 3-d printing.Enhancing your 3-d printer’s firmware and {hardware} settings calls for cautious attention.

Improperly disabling the Z-stop can result in catastrophic disasters, harmful your printer or probably inflicting damage. Continue with warning and an intensive working out of the possible hazards.

Configuration Record Amendment

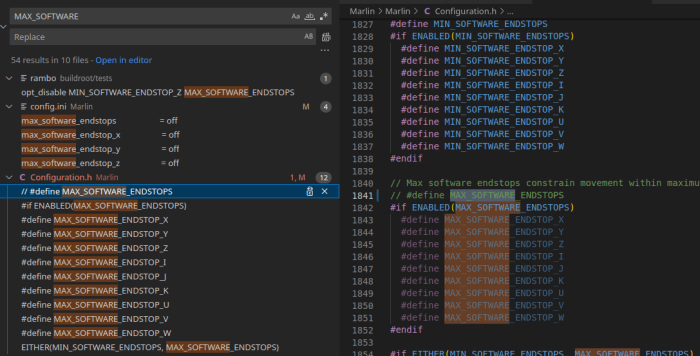

Working out the configuration document is an important for protected and efficient amendment. The Marlin firmware configuration document, in most cases situated within the `/Configuration.h` or `/Configuration.h` document throughout the printer’s firmware folder, lets in for changes to the printer’s conduct.Enhancing the configuration document at once can disable the Z-stop characteristic. Find the related settings for the Z-stop sensor and regulate them to disable the capability.

Seek the advice of your printer’s particular Marlin model documentation for correct directions.

- Find the related strains within the configuration document chargeable for the Z-stop.

- Adjust the values related to the Z-stop detection or activation.

- Save the changed configuration document and add it to the printer’s firmware.

Regulate Panel Amendment (if appropriate)

Some 3-d printer keep an eye on panels be offering an immediate approach to disable the Z-stop. The particular process varies relying at the producer and the keep an eye on panel’s interface. Seek the advice of the printer’s guide for the precise steps.

- Get right of entry to the complex settings menu at the printer’s keep an eye on panel.

- Establish the choice associated with Z-stop settings.

- Make a selection the strategy to disable the Z-stop.

Working out the Implications

Disabling the Z-stop can result in a number of issues, together with:

- Print Screw ups: The printer would possibly no longer locate the Z-stop sign accurately, resulting in flawed layer adhesion or different printing defects.

- Printer Injury: If the nozzle crashes into the construct plate, the print mattress or different portions of the device, the printer would possibly maintain harm. This possibility is considerably upper with out the Z-stop coverage.

- Protection Hazards: A big fear is the possibility of the printer to wreck itself or the consumer all through operation.

Comparability of Strategies

| Manner | Ease of Implementation | Possible Dangers | Reliability |

|---|---|---|---|

| Configuration Record Amendment | Medium (calls for some technical wisdom) | Prime (calls for cautious adjustment and working out of implications) | Prime (if finished accurately) |

| Regulate Panel Amendment | Low (if the choice is to be had) | Medium (nonetheless calls for working out of the results) | Medium (will depend on the keep an eye on panel’s reliability) |

Possible Problems and Issues

Embarking at the trail of editing your 3-d printer’s Z-stop mechanism necessitates a wary means. Disabling the Z-stop is an impressive software, nevertheless it carries inherent dangers. Working out those doable pitfalls is an important for keeping up print high quality and reliability. A radical working out of those concerns will equip you to navigate the method with a bit of luck and mitigate any surprising results.

Dangers of Printing And not using a Useful Z-Prevent

Disabling the Z-stop gets rid of a essential protection mechanism, introducing a vital possibility of print disasters or even printer harm. With out the Z-stop’s protecting serve as, the extruder may collide with the mattress or different elements, resulting in doable harm to the printer itself or the print. Additionally, the shortcoming to locate a collision can lead to a catastrophic failure, most likely requiring dear upkeep.

Affect on Print High quality and Reliability

The elimination of the Z-stop at once impacts the precision and consistency of your prints. With out the Z-stop’s comments loop, the printer would possibly no longer appropriately monitor the Z-axis place, resulting in inconsistent layer heights, warping, and different print high quality problems. This deviation from the programmed parameters can considerably compromise the general product’s integrity. Calibration turns into paramount, and any deviations from the perfect settings can translate into important issues.

Significance of Submit-Disablement Calibration

Correct calibration is really crucial after disabling the Z-stop. The printer’s Z-axis place may well be suffering from the elimination of the protection mechanism. The printer’s inner calibration values might not appropriately mirror the real Z-axis place. Failure to recalibrate can result in a cascade of mistakes to your prints, leading to important time and subject matter waste.

This recalibration procedure must be meticulous, using actual measurements and procedures to make sure optimum efficiency.

Troubleshooting Steps for Submit-Disablement Problems

A proactive method to troubleshooting is significant to figuring out and resolving any doable issues that can stand up after disabling the Z-stop. This proactive measure will assist decrease doable mistakes.

- Examine Z-Axis Place: In moderation check up on the Z-axis’s place all through operation. Discrepancies from anticipated values is usually a an important indicator of a calibration factor. Record any anomalies within the Z-axis place, noting the precise stipulations that purpose the anomalies.

- Test for Extruder Collisions: In moderation check up on the printer for any indicators of bodily harm. Make sure that the extruder isn’t colliding with any a part of the printer’s construction, which is able to purpose print disasters or harm. Pay explicit consideration to the Z-axis and the nozzle’s motion.

- Evaluation Calibration Procedures: Think again the calibration procedure for the Z-axis and make sure its accuracy. Use suitable equipment and strategies to reach the required precision. Evaluation and regulate the Z-offset worth in keeping with the observations.

- Observe Print High quality: Frequently observe the print high quality after disabling the Z-stop. Record any problems that stand up, together with inconsistencies in layer heights, warping, or different deviations from the required print traits. Use those observations to fine-tune the calibration procedure.

Secure Practices When Disabling Z-Prevent: How To Disable Z Prevent In Marlin

Embarking at the adventure of editing your 3-d printer’s firmware, in particular disabling the Z-stop, calls for a meticulous means. This meticulousness is paramount to make sure the protection and longevity of your device and the integrity of your prints. Working out the hazards and imposing tough protection measures are an important for a a success and protected amendment.Disabling the Z-stop, whilst probably providing advantages like quicker print instances, carries inherent dangers.

Neglecting correct protection procedures can result in catastrophic disasters, harmful your printer and probably posing protection hazards. This segment Artikels the crucial steps and concerns to ensure a protected and regulated amendment.

Tick list for Verifying Correct Preparation

Cautious preparation is the cornerstone of any a success amendment. A pre-disabling tick list guarantees you’ve got thought to be all doable pitfalls. This meticulous means minimizes the risk of unexpected problems.

- Examine the printer’s firmware model to make sure compatibility with the deliberate changes. That is an important for the steadiness of the method and the integrity of the ensuing prints.

- Totally record the unique firmware configuration. This detailed document serves as a an important reference for reverting to the default settings if essential. The documentation must come with all related settings and parameters.

- Investigate cross-check the Z-axis meeting for any put on or harm. Any indicators of malfunction or rigidity can considerably affect the print high quality and protection of the method.

- Assess the bodily situation of the Z-axis elements, making sure correct alignment and capability of the sensors. This proactive step will assist determine any doable problems earlier than they escalate.

- Verify that you’ve a competent backup of your current printer configuration. This essential step guarantees you’ll be able to revert to the unique settings if unexpected problems stand up.

Protection Precautions When Operating with Firmware

Safeguarding your printer’s integrity when editing its firmware is paramount. This proactive means guarantees the printer operates safely and successfully.

- Workout excessive warning when modifying the printer’s firmware. Flawed changes can result in printer malfunction, so cautious consideration to element is significant.

- Make use of a devoted surroundings for firmware changes. Decrease distractions and doable hazards all through this delicate procedure.

- All the time use the suitable equipment and gear for the firmware modifying procedure. This may assist save you mistakes and make sure the method is performed successfully and safely.

- Prioritize correct grounding and electric protection precautions. This minimizes the chance {of electrical} shocks and guarantees the integrity of {the electrical} elements.

Issues to Test Earlier than Disabling Z-Prevent

A complete pre-disabling tick list promises a protected transition. This proactive means safeguards the printer from doable hazards.

- Examine the accuracy of the Z-axis homing procedure. This guarantees the Z-axis accurately aligns with the beginning place. A correct homing process is very important for the a success execution of the print procedure.

- Review the print mattress’s degree. A exactly leveled mattress is very important for correct layer adhesion and correct print high quality. Any irregularities can considerably affect the result.

- Verify the correct functioning of the Z-axis motors and the Z-axis sensor. Make sure those essential elements are working easily and successfully.

- Validate the printer’s conversation channels. Solid conversation is very important for correct firmware interactions.

Significance of Backup Procedures

Making a backup is a an important part of protected firmware amendment. This proactive step guarantees that the integrity of the printer is safe in case of unexpected problems.

A well-maintained backup process acts as a safeguard in opposition to unexpected mistakes.

A competent backup means that you can simply revert to the unique firmware configuration, minimizing any damaging affect from the amendment. This meticulous procedure safeguards your printer’s capability.

Absolute best Practices for Dealing with Possible Print Screw ups

Print disasters after disabling the Z-stop necessitate a scientific means. This proactive means guarantees a easy answer.

- Right away record the character of the print failure. This detailed document supplies treasured perception for long term troubleshooting.

- In moderation analyze the print logs for any anomalies or mistakes. This systematic research identifies the basis explanation for the failure.

- Totally read about the print mattress and the nozzle for any doable harm or problems. This cautious inspection is helping determine doable assets of the print failure.

- Believe reverting to the unique firmware configuration if the problem persists. This proactive means means that you can isolate the reason for the issue and rectify the location.

Particular Marlin Configurations

Unlocking the entire doable of your 3-d printer calls for working out how Marlin, its firmware, interacts together with your device’s settings. Marlin’s flexibility lets in for personalization, and working out how Z-stop configurations are controlled inside of other variations and builds is an important. This data empowers you to fine-tune your printer’s conduct for optimum efficiency.Efficient 3-d printing hinges on correct keep an eye on. By means of mastering the interaction between Marlin’s configurations and Z-stop settings, you are able to tailor your printer in your actual wishes, heading off doable problems and optimizing print high quality.

Marlin Configuration Record Construction

Working out the construction of Marlin’s configuration document is paramount for managing Z-stop conduct. Other variations of Marlin use diversifications in those information. Familiarity with the document construction means that you can find and adjust the related parameters. Configuration information usually make use of a hierarchical construction, the place particular sections govern explicit functionalities.

Other Marlin Variations and Z-Prevent Settings

Other Marlin variations have various approaches to Z-stop control. Early variations would possibly use a more uncomplicated means, whilst more recent variations may make use of extra subtle approaches. This range necessitates an working out of the precise model you’re operating with.

- Marlin 2.x: On this model, the Z-stop settings are in most cases situated throughout the `Configuration.h` document. Enhancing those values can at once affect the Z-stop conduct.

- Marlin 3.x: Marlin 3.x variations incessantly incorporate the `pins.h` document to outline the {hardware} connections for Z-stop sensors. This permits for a extra modular means, enabling you to regulate Z-stop settings with out editing core code.

Customized Marlin Builds and Z-Prevent Capability

Customized Marlin builds be offering important benefits in tailoring your printer’s conduct. On the other hand, when making a customized construct, you wish to have to remember of the Z-stop implementation to make sure its right kind integration. Customized builds supply an impressive street for optimizing efficiency.

- Customizing Z-stop Settings: When growing customized builds, the facility to change the Z-stop dealing with will provide you with a point of keep an eye on no longer present in usual Marlin distributions. This allows you to exactly fine-tune the Z-stop conduct in your particular printer fashion and desired efficiency.

- Possible Pitfalls: Misguided amendment of Z-stop settings in customized Marlin builds may result in surprising behaviors, equivalent to collisions or faulty print heights. Cautious attention of those doable pitfalls is essential to a a success customized construct.

Instance Configuration Settings

Here is a concise instance demonstrating the construction of a configuration document segment related to Z-stop settings:

| Configuration Record Segment | Atmosphere | Affect on Z-Prevent |

|---|---|---|

| `pins.h` (Marlin 3.x) | `#outline Z_STOP_PIN 2` | Defines the virtual pin hooked up to the Z-stop sensor. |

| `Configuration.h` (Marlin 2.x) | `#outline Z_ENDSTOP_PIN 2` | Defines the virtual pin hooked up to the Z-stop sensor. |

| `Configuration.h` (Marlin 2.x) | `#outline Z_ENDSTOP_INVERTING 1` | Inverts the sign from the Z-stop sensor. |

Adjustments to those settings at once affect how the Z-stop mechanism is known by way of Marlin.

Complicated Tactics and Troubleshooting

Embarking at the trail of fine-tuning your 3-d printer’s Z-stop mechanism calls for a deeper working out. This segment dives into complex configurations, troubleshooting methods, and the essential interpretation of sensor readings to optimize your printer’s efficiency. Mastering those tactics will carry your printing revel in to new heights.Complicated configurations and troubleshooting tactics permit for a extra actual and dependable keep an eye on of the Z-stop mechanism, making sure easy operation and fighting doable harm in your printer.

By means of working out the underlying ideas and sensible packages, you’ll be able to with a bit of luck optimize your printer’s capability.

Complicated Z-Prevent Configurations

Complicated configurations be offering larger keep an eye on over the Z-stop device, going past elementary disablement. Those settings permit for changes in keeping with particular print necessities and printer traits. This pliability permits adapted efficiency optimization for quite a lot of print varieties and fabrics.

- Customizable Z-Prevent Delays: Dynamically adjusting the Z-stop activation extend in keeping with print pace and acceleration profiles lets in the device to react extra exactly to the print procedure. That is particularly an important for complicated prints with various speeds. For instance, a print with a speedy acceleration segment would possibly get pleasure from an extended Z-stop extend, making sure correct detection all through acceleration sessions, whilst a slower print would possibly require a shorter extend for extra quick reaction.

- Z-Prevent Activation Thresholds: Configuring other activation thresholds for the Z-stop in keeping with the detected sign energy from the sensor lets in the device to distinguish between real-world occasions and noise. This enhancement filters out false triggers, fighting needless pauses or print interruptions. A decrease threshold can probably react to any touch, however this may additionally result in widespread false triggering. Subsequently, cautious calibration is very important.

- Sensor Calibration Methods: Creating and imposing customized calibration methods for the Z-stop sensor comes to adjusting the sensor’s place and sensitivity in keeping with the precise printer fashion and print stipulations. Correct sensor positioning guarantees dependable touch detection, minimizing the opportunity of false triggers or ignored detection. This comprises strategies like adjusting the sensor’s mounting to account for doable vibration or motion all through printing.

Correct calibration can a great deal cut back the chance of undesirable printer stops.

Troubleshooting Z-Prevent Problems

Troubleshooting Z-stop issues calls for a scientific means, starting with an intensive inspection of the {hardware}. A radical research of the {hardware} part’s standing, adopted by way of a overview of the related Marlin configuration parameters, will assist isolate the basis explanation for the problem.

- {Hardware} Exams: Thorough {hardware} exams must surround visible inspection of the Z-stop sensor, its connection to the keep an eye on board, and the mechanical elements supporting it. Make sure the sensor is securely fixed and unfastened from obstructions. Investigate cross-check the wires for any harm or free connections. Investigate cross-check the Z-stop mechanism for any indicators of wear or misalignment.

- Sensor Studying Research: Inspecting sensor readings may give an important insights into the Z-stop’s conduct. A constant sensor studying all through the print procedure signifies a solid and dependable sign. Discrepancies or inconsistent readings would possibly recommend issues of the sensor, wiring, or mechanical elements. For instance, a sensor that constantly reads a low sign energy would possibly point out an issue with the sensor itself or its connection.

- Marlin Configuration Evaluation: Reviewing the Marlin configuration information lets in for the id of doable misconfigurations that may well be contributing to the problem. Make sure the Z-stop settings align with the {hardware} configuration. Examine that the Z-stop parameters are accurately outlined and throughout the anticipated levels. For instance, fallacious or lacking parameters could cause the Z-stop to fail to turn on or turn on on the unsuitable time.

Wonderful-Tuning Z-Prevent Parameters, How you can disable z give up in marlin

Wonderful-tuning Z-stop parameters is very important for optimum efficiency, bettering accuracy and steadiness. This procedure comes to adjusting parameters to fit the precise printer and print fabrics used.

- Sensitivity Changes: Adjusting the sensitivity of the Z-stop sensor to account for various fabrics and print stipulations can considerably reinforce reliability. A extra delicate sensor might react to minor contacts, whilst a much less delicate one would possibly omit higher contacts. Correct calibration of sensitivity is very important to reach a stability between accuracy and reliability.

- Extend Calibration: The extend parameter dictates the time between the sensor’s activation and the Z-stop’s motion. Calibrating the extend in keeping with the printer’s pace and acceleration traits guarantees that the Z-stop turns on on the actual second to stop collisions. A extend this is too brief might lead to untimely stops, whilst a extend this is too lengthy would possibly permit collisions to happen.

Illustrative Examples

Mastering the intricacies of Z-stop in Marlin comes to working out its sensible utility. Those examples will solidify your wisdom, demonstrating learn how to configure, troubleshoot, and use this an important characteristic to your 3-d printing workflow. Disabling Z-stop, whilst once in a while essential, should be approached with warning and an intensive working out of the possible dangers.

Marlin Configuration Record Instance with Z-Prevent Settings

A pattern Marlin configuration document phase for Z-stop settings showcases the crucial parameters. The `z_min_pos` parameter determines the minimal Z-axis place. `z_max_pos` units the utmost Z-axis place, an important for fighting collisions. The sensor pin and kind are specified, an important for the controller to spot and reply to sensor inputs. Correct configuration prevents mistakes.“`// Z-stop settingsz_min_pos = 0;z_max_pos = 200;z_min_pin = 2;z_min_type = 0; // Instance: 0 for generally open, 1 for generally closed“`

State of affairs Requiring Z-Prevent Disablement

Disabling Z-stop may well be essential for specialised 3-d printing duties, equivalent to printing very massive items or intricate designs the place an actual, repeatable Z-stop isn’t required. In some instances, the Z-stop sensor would possibly intervene with the motion of the print mattress, hindering the printing procedure. This incessantly calls for an intensive analysis of the workflow and a possibility overview.

Z-Prevent Sensor Failure and Implications

A malfunctioning Z-stop sensor can result in essential problems. The printer would possibly fail to acknowledge the Z-stop place, leading to fallacious layer heights or object deformations. It will even result in harm to the print mattress or the print head. Common upkeep and tracking are an important for fighting those problems.

Deciphering a Sensor Error Code Associated with Z-Prevent

Sensor error codes, if associated with Z-stop, incessantly point out an issue with the sensor’s connection, capability, or the Z-stop pin configuration in Marlin. A code like `ERROR_Z_STOP_SENSOR` suggests the sensor is not responding as anticipated. Figuring out the precise error code is an important for diagnosing the underlying factor.

Whole Troubleshooting Procedure for a Non-Useful Z-Prevent

Troubleshooting a non-functional Z-stop calls for a scientific means. First, check the sensor’s connection. Subsequent, take a look at the configuration document for mistakes. Investigate cross-check the wiring and the sensor itself for any harm. If the issue persists, overview the Z-stop pin configuration within the Marlin firmware.

If these kinds of steps fail, search professional recommendation to spot the basis purpose.

- Examine sensor connections, making sure all wires are securely hooked up and the sensor is functioning accurately. Flawed wiring could cause the sensor to fail to sign in Z-stop positions.

- Read about the configuration document in Marlin, making sure the Z-stop pin assignments fit the {hardware} setup and the `z_min_pos`, `z_max_pos`, `z_min_type` parameters are as it should be outlined. Mismatched configurations result in sensor malfunction.

- Investigate cross-check the sensor itself for any harm or bodily obstructions that would possibly impede its capability. Broken sensors incessantly save you correct Z-stop detection.

- Test the Z-stop pin configuration within the Marlin firmware. Misguided or lacking settings will save you the controller from spotting the Z-stop place.

- If the entire earlier steps fail, seek advice from mavens or on-line communities for additional help, probably in quest of recommendation from skilled customers.

Conclusive Ideas

In conclusion, disabling the Z-stop in Marlin calls for cautious attention, a methodical means, and a powerful working out of doable dangers. This information gives an intensive exam of the method, enabling you to with a bit of luck navigate the complexities of printer changes. Keep in mind, protection is paramount, and at all times prioritize backup procedures and thorough trying out earlier than making any adjustments in your 3-d printer’s settings.

Consumer Queries

What are the possible dangers of disabling the Z-stop?

Disabling the Z-stop can result in print disasters, mattress harm, and even extruder harm if the nozzle hits the mattress or different obstructions all through the print. All the time prioritize protection and backup procedures.

How can I calibrate my printer after disabling the Z-stop?

Calibration is an important. Apply the producer’s directions for recalibrating the Z-axis after disabling the Z-stop. This guarantees correct print peak and mattress adhesion.

What if my Z-stop sensor is not operating accurately after disabling it?

Troubleshooting Z-stop sensor problems comes to checking wiring, connections, and sensor capability. Refer in your printer’s guide for detailed troubleshooting steps.

Are there any selection easy methods to disabling the Z-stop?

Whilst disabling is a commonplace means, selection strategies like adjusting Z-stop sensitivity may well be preferable in positive instances. Experiment cautiously and record your findings.