Methods to reduce alumina? This information dives deep into the sector of alumina slicing, masking the entirety from its houses to the most efficient strategies and protection precautions. We’re going to discover the quite a lot of varieties of alumina, their distinctive traits, and the way those impact the slicing procedure. From mechanical laser slicing, we’re going to dissect the benefits and downsides of each and every methodology.

Working out alumina’s houses is the most important for secure and environment friendly slicing. This complete information will equip you with the data and gear to take on alumina slicing initiatives with self belief, from preliminary number of the best approach to post-cutting concerns.

Creation to Alumina Slicing

Alumina, often referred to as aluminum oxide (Al 2O 3), is a the most important commercial subject material prized for its remarkable hardness, excessive melting level, and very good chemical resistance. Its numerous packages span quite a lot of sectors, from high-performance ceramics to complicated engineering parts. Working out the several types of alumina and their explicit houses is paramount for efficient and secure slicing processes.Alumina exists in quite a lot of crystalline paperwork, each and every with distinctive traits impacting its machinability.

Commonplace paperwork come with alpha-alumina, beta-alumina, and others. Alpha-alumina, as an example, most often reveals upper hardness and a extra strong construction than beta-alumina. This structural variation influences the slicing forces and gear put on all through machining operations.Slicing alumina calls for cautious attention of its houses. Commonplace packages the place alumina slicing is very important come with production of high-precision gear, aerospace parts, and complicated ceramic portions.

Failure to account for alumina’s numerous traits can result in important demanding situations achieve desired slicing accuracy and gear existence. Working out the connection between the particular alumina sort and the desired slicing parameters is important for environment friendly and secure operations.

Alumina Sorts and Houses

Various kinds of alumina show off various levels of hardness and melting issues, considerably impacting the slicing procedure. Working out those variations is the most important for deciding on the right slicing gear and parameters.

- Alpha-alumina, recognized for its excessive hardness and balance, frequently gifts a more difficult slicing state of affairs in comparison to different varieties. Its awesome put on resistance, then again, permits for using explicit slicing gear, and exact keep watch over of slicing parameters.

- Beta-alumina, with relatively decrease hardness in comparison to alpha-alumina, typically permits for sooner slicing speeds. Then again, the decrease hardness may require using harder slicing gear to take care of the required slicing precision and save you device failure.

Comparability of Alumina Sorts

The desk beneath highlights the comparative hardness and melting level of quite a lot of alumina varieties. Those values are essential in deciding on suitable slicing gear and procedures.

| Alumina Kind | Hardness (Mohs Scale) | Melting Level (°C) |

|---|---|---|

| Alpha-alumina | 9 | 2050-2072 |

| Beta-alumina | 8.5-9 | 2072 |

| Delta-alumina | 9 | 2050-2072 |

| Theta-alumina | 9 | 2050-2072 |

Strategies for Slicing Alumina

Alumina, a extremely flexible and powerful subject material, unearths packages in numerous industries, from aerospace to production. Its remarkable hardness and energy necessitate specialised slicing tactics. Other mechanical strategies be offering various levels of precision, cost-effectiveness, and subject material removing charges, each and every with its personal set of benefits and downsides. Working out those nuances is the most important for deciding on the right slicing means for a selected utility.The collection of slicing means for alumina relies on elements similar to the required precision, the scale and form of the workpiece, the desired subject material removing charge, and the funds constraints.

Every means gifts a singular trade-off between those elements, influencing the whole potency and value of the producing procedure.

Mechanical Slicing Strategies

Quite a lot of mechanical strategies are hired for slicing alumina, each and every with its personal traits. Those strategies come with grinding, sawing, and laser slicing, each and every providing distinctive advantages and downsides. The number of probably the most appropriate means relies on the particular necessities of the applying.

Grinding

Grinding is a not unusual mechanical slicing means for shaping alumina parts. It comes to using abrasive gear to steadily take away subject material from the workpiece. This system is especially efficient for reaching exact shapes and complex main points.

- Benefits: Grinding permits for top precision and the introduction of complicated geometries. It’s appropriate for generating extremely completed surfaces.

- Disadvantages: Grinding is usually a fairly sluggish procedure, specifically for massive workpieces. It may possibly additionally generate an important quantity of warmth, which is able to impact the integrity of the alumina. The price of specialised grinding package may also be excessive.

Sawing

Sawing, some other mechanical slicing methodology, employs a noticed blade with abrasive tooth to chop in the course of the alumina. This system is frequently selected for its skill to chop massive items briefly and successfully.

- Benefits: Sawing is typically sooner than grinding for better parts and not more exact cuts. It may be used for a much wider vary of alumina grades. It’s appropriate for slicing fairly easy shapes.

- Disadvantages: The precision of sawing is frequently not up to grinding, making it much less appropriate for intricate geometries. The noticed blade can change into uninteresting and require common alternative. The ensuing floor end is frequently much less clean than grinding.

Laser Slicing

Laser slicing makes use of a high-powered laser beam to vaporize or soften the alumina subject material. This system provides excessive precision and permits for complicated slicing patterns.

- Benefits: Laser slicing is phenomenally exact and will produce intricate patterns. It generates minimum warmth enter, which may also be really helpful for sure alumina varieties. The method is speedy and environment friendly, appropriate for high-volume manufacturing.

- Disadvantages: Laser slicing package is costly. The method may also be restricted by means of the fabric thickness, and the price of the slicing subject material may also be excessive for thicker alumina items.

Have an effect on of Slicing Parameters

Slicing velocity and feed charge considerably impact the standard of the reduce. Upper slicing speeds can result in sooner subject material removing, however would possibly lead to higher warmth technology and lowered precision. Optimum feed charges wish to be moderately balanced to reduce device put on and make sure clean subject material removing.

Abrasive Equipment

Abrasive gear, similar to grinding wheels and slicing blades, are the most important for successfully slicing alumina. Those gear use abrasive debris to take away subject material from the workpiece. The number of the right abrasive subject material and grain measurement relies on the particular alumina grade and the required end.

Apparatus Comparability

| Slicing Way | Apparatus Required |

|---|---|

| Grinding | Grinding system, abrasive wheels, coolant machine |

| Sawing | Sawing system, noticed blade, coolant machine |

| Laser Slicing | Laser slicing system, specialised alumina slicing parameters |

Precision Comparability

The precision achievable with each and every means varies. Laser slicing typically provides the best precision, adopted by means of grinding. Sawing supplies the bottom precision, making it appropriate simplest for easy shapes.

Components Affecting Alumina Slicing

Alumina, famend for its remarkable hardness and energy, gifts distinctive demanding situations all through the slicing procedure. Working out the standards influencing the number of a slicing means is the most important for reaching optimum effects and minimizing doable dangers. Those elements surround subject material houses, slicing parameters, and protection concerns. The collection of slicing means considerably affects the overall product high quality, charge, and protection.Subject material traits, together with hardness and brittleness, considerably affect the slicing procedure.

The number of slicing gear and techniques at once correlates with the required floor end and the tolerance for doable harm. Temperature fluctuations all through the slicing procedure too can impact the overall consequence.

Subject material Houses and Their Have an effect on

The inherent hardness and brittleness of alumina at once affect the collection of slicing means. Extraordinarily difficult fabrics like alumina require specialised gear and methods to forestall untimely device put on and make sure blank cuts. Brittleness, a function of alumina, predisposes it to chipping and cracking all through the slicing procedure. This assets necessitates cautious attention of slicing velocity and feed charges to reduce such occurrences.

The number of the best slicing device geometry may be the most important to scale back the potential of chipping.

Function of Slicing Fluids (if used)

Slicing fluids, when used, play an important function in minimizing friction and warmth buildup all through the slicing procedure. Lubrication and cooling, the main purposes of those fluids, cut back the danger of device put on and take care of a strong slicing setting. The number of the right slicing fluid relies on the particular alumina grade and the slicing means hired. Right kind lubrication and cooling make stronger the potency and protection of the slicing procedure.

Opting for the incorrect fluid can result in problems similar to device harm, subject material contamination, and even protection hazards.

Protection Hazards and Preventive Measures

Alumina slicing can pose a number of protection hazards, together with the technology of sharp fragments and dirt debris. Those debris may also be inhaled, resulting in respiration problems. Top temperatures generated all through slicing could cause burns or ignite flammable fabrics. Protecting package, similar to protection glasses, respirators, and suitable clothes, is very important for minimizing the dangers related to alumina slicing.

Ok air flow techniques will have to be in position to keep watch over mud and fumes. Right kind dealing with and garage of slicing fluids also are the most important protection concerns.

- Doable Hazards: Sharp fragments, mud inhalation, excessive temperatures, flammable fabrics, eye accidents, and pores and skin touch with slicing fluids.

- Preventive Measures: Suitable non-public protecting package (PPE), together with protection glasses, respirators, and protecting clothes; ok air flow; correct dealing with and garage of slicing fluids; and a secure running setting.

Impact of Temperature on Alumina Throughout Slicing

Top temperatures generated all through the slicing procedure can impact the microstructure and houses of the alumina. Increased temperatures can result in thermal pressure and doubtlessly impact the dimensional accuracy of the workpiece. Cautious keep watch over of slicing parameters, similar to velocity and feed, is the most important to regulate the temperature generated all through the slicing procedure. The usage of slicing fluids, as discussed previous, performs an important function in dissipating warmth and keeping up a secure slicing setting.

Choice of the right slicing fluid can at once affect the temperature control all through the method.

Subject material Thickness, Desired Form, and Floor End

The fabric thickness considerably affects the collection of slicing means. Thicker fabrics frequently require extra tough slicing gear and specialised tactics. The specified form and floor end of the alumina additionally play an important function within the number of the slicing means. Precision slicing strategies are crucial for reaching intricate shapes and high quality floor finishes. The tolerance for floor imperfections and dimensional accuracy additionally at once impacts the number of the slicing means.

Protection Precautions Throughout Alumina Slicing

Alumina, a troublesome and chemically inert subject material, calls for specialised slicing tactics and stringent protection measures. Unsuitable procedures can result in important well being dangers. Working out and adhering to protection precautions is the most important to combating accidents and keeping up a secure running setting all through alumina slicing operations.Efficient protection measures are paramount all through alumina slicing because of the potential of hazardous mud debris and equipment-related dangers.

By way of prioritizing protection, staff can decrease the possibility of injuries and take care of a wholesome and productive paintings setting.

Non-public Protecting Apparatus (PPE)

Ok non-public protecting package (PPE) is very important for mitigating well being hazards all through alumina slicing. This contains specialised clothes and tool designed to protect staff from airborne contaminants and doable bodily hazards. Failure to make use of correct PPE can lead to important well being problems.

- Eye Coverage: Protection glasses or full-face shields are necessary to offer protection to the eyes from flying particles and dirt debris.

- Breathing Coverage: Respirators with suitable filters are essential to clear out destructive alumina mud, particularly all through high-intensity slicing operations. The kind of respirator relies on the particular slicing means and the focus of alumina mud within the air. Right kind respirator are compatible and upkeep are essential.

- Pores and skin Coverage: Gloves and protecting clothes are crucial to forestall pores and skin touch with alumina mud and doable chemical contaminants, particularly all through grinding and different floor preparation steps.

- Listening to Coverage: If the slicing procedure produces important noise, listening to coverage similar to earplugs or earmuffs will have to be worn to forestall listening to loss.

Well being Hazards Related to Alumina Mud

Alumina mud inhalation can result in quite a lot of respiration issues, together with silicosis, an irreversible lung illness. Extended publicity to alumina mud could cause inflammation to the surface, eyes, and respiration tract. Suitable protection measures are essential to mitigate those dangers.

- Breathing Problems: Inhalation of alumina mud can result in a spread of respiration problems, from delicate inflammation to critical lung sicknesses like silicosis. Signs of respiration issues may also be not on time, making common well being tracking the most important.

- Pores and skin Inflammation: Direct touch with alumina mud could cause pores and skin inflammation, dryness, and hypersensitive reactions. Widespread washing and use of protecting lotions can cut back those dangers.

- Eye Inflammation: Flying particles and dirt all through slicing operations could cause eye inflammation, resulting in discomfort and doubtlessly extra critical accidents.

Particular Protection Pointers for Every Slicing Way, Methods to reduce alumina

The particular protection precautions rely at the slicing means hired. Every means gifts its personal set of dangers and calls for adapted protection protocols. Following those pointers minimizes the danger of injuries.

| Slicing Way | Protection Apparatus | Protection Procedures |

|---|---|---|

| Waterjet Slicing | Complete-face protect, protection glasses, respirators, gloves, and water resistant clothes. | Deal with ok water strain and go with the flow to successfully keep watch over mud. Stay the world well-ventilated. Put on correct PPE all the time. |

| Laser Slicing | Eye coverage, respirators, and protection glasses. | Make sure the laser slicing enclosure is correctly sealed and ventilated. Use suitable respiration coverage. Common upkeep of the laser slicing system is very important to forestall hazards. |

| Plasma Slicing | Complete-face protect, protection glasses, respirators, gloves, and listening to coverage. | Deal with ok air flow and use correct respiration coverage. Make sure the plasma slicing system is correctly grounded. Stay a secure distance from the slicing space. |

Emergency Procedures

Organising transparent emergency procedures is necessary in case of injuries all through alumina slicing operations. A well-defined plan can decrease the affect of incidents and make sure swift and efficient responses.

- First Support: Make sure skilled group of workers are readily to be had to manage first assist in case of accidents. Emergency scientific services and products will have to be straight away contacted for critical accidents.

- Evacuation: Increase a transparent evacuation plan in case of fireside or different emergencies. Make sure all staff are acutely aware of the evacuation routes.

- Reporting: Identify a machine for reporting all incidents, regardless of how minor. Complete reporting permits for id of patterns and growth of protection procedures.

Waste Disposal

Right kind disposal of waste generated all through alumina slicing is the most important to forestall environmental contamination. Alumina mud and different fabrics want cautious dealing with to reduce environmental affect.

- Mud Assortment: Make the most of mud assortment techniques to seize alumina mud and different waste fabrics generated all through the slicing procedure.

- Right kind Garage: Retailer gathered mud and waste fabrics in designated, sealed packing containers to forestall leakage and contamination.

- Regulatory Compliance: Adhere to all native, state, and federal laws for waste disposal and dealing with.

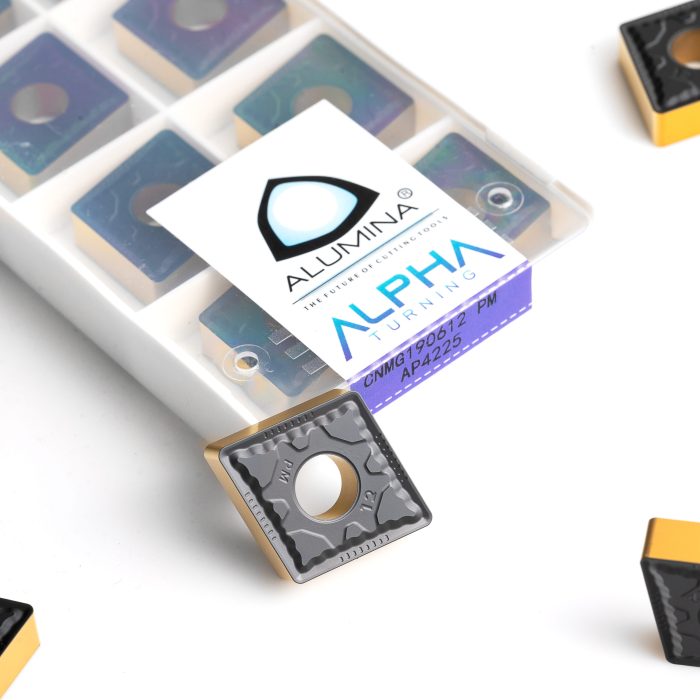

Equipment and Apparatus for Alumina Slicing

Alumina, because of its excessive hardness and energy, necessitates specialised gear and gear for environment friendly and secure slicing. Settling on the right kind gear is important to reaching blank cuts, minimizing subject material waste, and making sure operator protection. This phase main points the quite a lot of gear and gear hired in several alumina slicing strategies, emphasizing their functionalities and suitability for explicit alumina varieties.Efficient alumina slicing will depend on a mix of things, together with the slicing device’s subject material, design, and sharpness, along side the package’s skill to use the desired power and keep watch over the slicing procedure.

Opting for the correct mix is very important for minimizing subject material harm and maximizing slicing potency.

Particular Equipment for Abrasive Slicing

Abrasive slicing strategies are usually used for alumina because of their skill to successfully take away subject material with out inflicting over the top warmth buildup. Various kinds of abrasive gear are used, each and every with various specs and features.

- Abrasive Wheels: Those wheels are composed of abrasive grains bonded to a backing subject material. The kind and measurement of abrasive grains, along side the wheel’s construction, considerably affect the slicing functionality. For example, high-performance alumina slicing wheels frequently make the most of diamond or CBN (cubic boron nitride) abrasive grains for his or her awesome hardness and sturdiness. The wheel’s diameter, thickness, and mounting means are essential parameters for optimum slicing functionality.

- Abrasive Cutters: Those are specialised gear with abrasive surfaces that at once touch the alumina. They’re frequently used together with a slicing system for exact and regulated slicing. The particular abrasive subject material and the cutter’s geometry are key elements affecting slicing velocity and floor end.

- Grinding Disks/Wheels: Those gear are used for smoothing and completing reduce surfaces after the preliminary slicing operation. The grit measurement and form of abrasive subject material decide the extent of floor refinement accomplished. Other alumina grades would possibly necessitate other grinding disk specs for reaching optimum effects.

Particular Equipment for Non-Abrasive Slicing

Whilst abrasive slicing is prevalent, different strategies, similar to waterjet slicing, are appropriate for sure alumina varieties and packages.

- Waterjet Slicing Apparatus: This system makes use of a high-pressure water flow to chop in the course of the subject material. Specialised nozzles and pumps are the most important for reaching the essential strain and precision. Waterjet slicing is especially appropriate for intricate shapes and skinny sections of alumina because of its minimum warmth technology and exact slicing features.

- Laser Slicing Apparatus: Laser slicing employs a targeted laser beam to vaporize or soften the alumina subject material. The laser’s energy and center of attention are essential for reaching exact cuts and minimizing subject material distortion. Laser slicing is efficacious for complicated shapes and high-precision packages. Other laser varieties (e.g., CO2, fiber) could have other features when slicing quite a lot of alumina grades.

Software Variety Standards

The collection of slicing gear is dependent closely at the houses of the alumina subject material being reduce.

| Alumina Kind | Appropriate Slicing Software | Specs |

|---|---|---|

| Top-purity, hard-grade alumina | Diamond-impregnated abrasive wheels or CBN abrasive cutters | Top hardness, sturdiness, and resistance to put on are crucial. |

| Medium-hardness alumina | Silicon carbide abrasive wheels or waterjet slicing | Average hardness and energy; appropriate for quite a lot of packages. |

| Cushy alumina | Waterjet or laser slicing | Decrease hardness; waterjet or laser slicing are extra appropriate for minimizing thermal harm. |

Upkeep Procedures

Right kind upkeep of slicing gear and gear is necessary for optimum functionality and protection.

- Common Inspection: Investigate cross-check gear for harm, put on, and sharpness ahead of each and every use. Investigate cross-check slicing package for leaks, clogs, and correct capability. This can be a essential step to forestall injuries.

- Cleansing: Blank abrasive gear after each and every use to take away alumina debris and particles, combating clogging and untimely put on. This additionally complements the device’s lifespan.

- Polishing/Alternative: Sharpen or exchange abrasive gear as had to take care of their leading edge. That is the most important for making sure constant slicing functionality. Alternative is very important if the device displays indicators of over the top put on or harm.

- Apparatus Servicing: Agenda common servicing and upkeep for waterjet or laser slicing package, making sure the machine operates at optimum strain and potency.

Slicing Parameters for Alumina

Optimizing slicing parameters is the most important for reaching high quality cuts in alumina whilst minimizing subject material waste and gear put on. Settling on suitable slicing velocity, feed charge, and intensity of reduce at once affects the potency and precision of the slicing procedure. Working out the interaction between those parameters and the particular form of alumina being labored with is paramount.

Have an effect on of Alumina Kind on Slicing Parameters

Various kinds of alumina show off various hardness and fracture toughness, considerably influencing the optimum slicing parameters. For instance, high-purity alumina, frequently utilized in high-precision packages, calls for a extra subtle method than coarse-grained alumina hired in structural parts. Working out those subject material houses is very important for opting for the right kind slicing parameters to verify a blank reduce with out over the top device put on or subject material harm.

Slicing Pace, Feed Price, and Intensity of Lower

Those 3 parameters are basic to the alumina slicing procedure. Slicing velocity, measured in meters according to minute (m/min), determines the speed at which the slicing device interacts with the fabric. Feed charge, measured in millimeters according to revolution (mm/rev), controls the speed at which the slicing device advances alongside the workpiece. Intensity of reduce, measured in millimeters (mm), defines the fabric removing charge.

The interaction between those parameters is complicated and calls for cautious attention to steer clear of over the top device put on, subject material harm, and inconsistent cuts.

Optimizing Slicing Parameters

A scientific way to optimizing slicing parameters comes to a number of key tactics. Experimentation with other parameter combos is the most important to spot the optimum settings for explicit alumina varieties and slicing strategies. Tracking device put on and subject material removing charge all through the slicing procedure supplies precious comments for adjusting parameters. Using computer-aided design (CAD) and computer-aided production (CAM) instrument can help in growing exact slicing paths and estimating the desired slicing parameters.

Making an allowance for the particular utility and desired floor end additionally performs an important function in deciding on the optimum parameters.

Examples of Slicing Parameters for Other Alumina Sorts and Programs

| Alumina Kind | Slicing Way | Slicing Pace (m/min) | Feed Price (mm/rev) | Intensity of Lower (mm) |

|---|---|---|---|---|

| Top-purity alumina (99.9%) | Twine EDM | 10-20 | 0.05-0.1 | 0.1-0.2 |

| Coarse-grained alumina (80%) | CNC milling | 50-100 | 0.2-0.5 | 1-2 |

| Alumina ceramic | Waterjet | Variable (depending on nozzle strain and water go with the flow charge) | Variable | Variable (depending on nozzle measurement and subject material thickness) |

Those are simply examples and exact values would possibly range considerably in response to explicit alumina traits, tooling, and system features.

Significance of Constant Slicing Parameters

Keeping up constant slicing parameters is paramount for reaching high quality cuts in alumina. Diversifications in those parameters can result in inconsistent floor finishes, untimely device put on, and subject material defects. Imposing standardized procedures and using computerized keep watch over techniques can assist take care of constant parameters all through the slicing procedure. Common tracking and adjustment of parameters are necessary to verify constant high quality and productiveness.

Publish-Slicing Issues: How To Lower Alumina

Publish-cutting procedures for alumina are the most important for reaching the required floor high quality and making sure the overall product meets specs. Right kind floor completing and high quality keep watch over steps decrease imperfections, toughen the fabric’s functionality, and save you doable problems all through next processing levels. This phase main points the essential steps desirous about post-cutting alumina, together with floor completing strategies, high quality keep watch over procedures, and the affect of floor high quality at the ultimate product.

Floor Completing Strategies for Alumina

Floor completing is very important for reaching the desired floor high quality in alumina parts. The collection of completing means relies on the particular utility and the required floor traits, together with roughness, flatness, and dimensional accuracy. Other strategies be offering various levels of precision and potency.

- Grinding: Grinding is a not unusual floor completing methodology for alumina, specifically for reaching a clean floor end. Abrasive grinding wheels take away subject material from the outside, leading to a managed aid in floor roughness. The number of grinding wheels, grit measurement, and strain is the most important to steer clear of unwanted floor harm or over the top subject material removing. This system is efficacious for reaching excessive precision and dimensional accuracy in quite a lot of alumina packages.

- Sharpening: Sharpening is hired to refine the outside additional, frequently after grinding. Sharpening makes use of finer abrasives and a sharpening compound to reach a mirror-like end. This system is very important for packages requiring exceptionally clean surfaces, similar to optical parts or high-precision portions. Sharpening gets rid of microscopic scratches and irregularities left at the back of by means of grinding, considerably bettering the outside high quality.

- Lapping: Lapping is some other floor completing methodology used to reach a extremely exact and clean floor end. It makes use of a flat lapping plate and a wonderful abrasive slurry to create a uniform floor. This system is frequently used together with grinding or sharpening to reach a last, high quality end. It is specifically appropriate for parts requiring exact dimensional tolerances and an excessively low floor roughness.

- Chemical Etching: Chemical etching is a chemical procedure that selectively gets rid of subject material from the outside of alumina. It is frequently used to toughen the outside end and take away floor imperfections. The chemical resolution and etching time are moderately managed to verify constant effects and steer clear of harm to the underlying subject material. This system may also be efficient in growing a selected floor texture or eliminating floor contamination.

High quality Keep watch over Procedures for Lower Surfaces

Rigorous high quality keep watch over is very important to verify the reduce surfaces of alumina meet the desired requirements. Those procedures test the dimensional accuracy, floor roughness, and lack of defects, making sure the integrity and reliability of the completed product.

- Dimensional Inspection: Measuring the scale of the reduce alumina portions towards the desired tolerances is the most important. This comes to the usage of quite a lot of measuring tools, similar to calipers, micrometers, and coordinate measuring machines (CMMs), to verify the portions meet the desired dimensions. Those measurements are crucial to make sure that the phase suits into the meant meeting.

- Floor Roughness Size: Measuring floor roughness the usage of floor roughness tools, similar to profilometers, is helping decide the smoothness of the reduce floor. This size supplies knowledge at the moderate floor roughness, which is a essential think about comparing the standard of the completed product. Other packages require various ranges of floor roughness, so exact measurements are crucial.

- Visible Inspection: Visible inspection of the reduce surfaces is frequently carried out to spot any defects, similar to cracks, chips, or different irregularities. Skilled group of workers read about the surfaces for visible imperfections, making sure that the reduce surfaces are unfastened from flaws. Visible inspection may also be complemented with different strategies for complete high quality keep watch over.

- Subject material Research: In some instances, subject material research is carried out to evaluate the chemical composition and microstructure of the reduce surfaces. This is helping decide if the slicing procedure has offered any unwanted adjustments or contaminants. Subject material research can stumble on microscopic defects that may not be visual thru visible inspection.

Floor Completing Examples for Other Programs

The fitting floor completing methodology relies on the particular utility of the alumina part.

- Optical Parts: Sharpening is the most well liked floor completing means for optical parts. The excessive stage of smoothness and flatness acquired thru sharpening guarantees optimum mild transmission and mirrored image, the most important for packages like lenses and prisms.

- Bearing Surfaces: Grinding adopted by means of lapping is frequently used to arrange bearing surfaces for enhanced put on resistance and lowered friction. This mix guarantees an actual floor end and correct dimensional accuracy for the bearing’s capability.

- Structural Parts: Grinding is usually used for structural parts. The process supplies a stability between floor end and dimensional accuracy, appropriate for packages requiring excessive mechanical energy.

Ultimate Wrap-Up

In conclusion, slicing alumina successfully comes to cautious attention of its distinctive houses, the selected means, and meticulous adherence to protection protocols. This information supplied a powerful review of all the procedure, from preliminary subject material characterization to post-cutting floor completing. By way of figuring out the nuances of alumina slicing, you’ll be able to make certain a success results and challenge crowning glory.

FAQs

What are the commonest varieties of alumina utilized in slicing packages?

Alpha and beta alumina are not unusual varieties. Alpha alumina is typically tougher and extra strong, whilst beta alumina can have other houses relying at the explicit utility.

What are the prospective well being hazards related to alumina mud?

Breathing in alumina mud could cause respiration problems. All the time put on suitable respiration coverage and apply protection pointers to mitigate those dangers.

What are some examples of floor completing strategies for alumina?

Grinding, sharpening, and chemical etching are examples of floor completing tactics. The selected means relies on the required floor high quality and alertness.

What elements affect the number of a slicing means for alumina?

Components similar to subject material thickness, desired form, floor end, and funds affect the collection of slicing means. Believe the trade-offs between velocity, precision, and value.