The right way to calculate {that a} bolt may not come unfastened? This dives into the a very powerful components figuring out bolt longevity and safety. Free bolts are a big headache in equipment, building, and cars, resulting in pricey upkeep and protection hazards. Figuring out the science in the back of bolt balance is essential to combating those problems.

We will discover the whole thing from correct bolt tensioning ways to the affect of environmental components. Various kinds of bolts, fasteners, and preventative measures shall be analyzed, permitting you to with a bit of luck design and handle protected connections. We will quilt the whole thing from torque wrenches to fasten washers, equipping you with the information to stop pricey and probably unhealthy scenarios.

Advent to Fighting Bolt Loosening

A important but ceaselessly overpassed facet of engineering and building is the prevention of bolt loosening. This reputedly easy factor can result in catastrophic screw ups, jeopardizing protection and inflicting really extensive monetary losses. From the sophisticated mechanisms of a high-precision watch to the immense structural integrity of a bridge, the safety of fasteners like bolts is paramount. The effects of unfastened bolts are far-reaching, impacting the whole thing from day by day commutes to the security of important infrastructure.The failure of a unmarried bolt, left unaddressed, can cascade into greater issues.

Believe a unfastened bolt on a important engine element resulting in catastrophic engine failure. Or, imagine the consequences of a unfastened bolt in a construction’s structural fortify gadget, probably resulting in cave in. Those don’t seem to be hypothetical eventualities; they constitute real-world dangers, highlighting the pressing want for proactive measures to handle fastener integrity.

Forms of Bolts and Fasteners

A big selection of bolts and fasteners are used throughout quite a lot of industries, each and every with distinctive traits. Figuring out the variations between those varieties is a very powerful for deciding on the proper fastener for a given utility. Commonplace varieties come with gadget screws, carriage bolts, lag bolts, and quite a lot of varieties of cap screws. Every kind is designed for particular packages and cargo stipulations.

For instance, gadget screws are recurrently utilized in mechanical assemblies, whilst carriage bolts are used for becoming a member of wooden. Figuring out the proper fastener for the activity is very important.

Forces Inflicting Bolt Loosening

A number of components give a contribution to bolt loosening over the years. Those come with vibration, cyclical a lot, and thermal growth and contraction. Those forces, despite the fact that ceaselessly refined, can gather over the years, progressively decreasing the clamping drive of the fastener. The impact of those forces is ceaselessly extra pronounced in high-vibration environments, reminiscent of in equipment or cars. Moreover, repeated loading and unloading, like in a building web site, too can result in the weakening of the bolt’s retaining energy.

For instance, a poorly designed or maintained piece of kit is extra at risk of experiencing this slow loosening.

Comparability of Bolt Securing Strategies

| Securing Approach | Strengths | Weaknesses |

|---|---|---|

| Thread Locking Compound | Efficient in combating loosening because of vibration and cyclic a lot; rather simple to use; cost-effective. | Will also be suffering from temperature fluctuations; might require a couple of packages; possible for some chemical residue. |

| Lock Washers | Easy to make use of; supply further clamping drive; cost-effective. | Effectiveness is determined by the fabric and design of the washing machine; can also be at risk of injury if no longer put in accurately. |

| Nylock Nuts | Superb resistance to loosening because of vibration and cyclic a lot; ceaselessly utilized in high-vibration packages; just right self-locking characteristic. | Will also be costlier than usual nuts; might require particular gear for set up. |

| Prime-Power Bolts | Awesome tensile energy and fatigue resistance; ceaselessly utilized in important packages; can face up to excessive strain ranges. | Costlier; might require specialised set up procedures. |

Figuring out the strengths and weaknesses of various strategies is necessary for opting for the optimum answer for a selected utility.

Preventive Measures

Keeping up fastener integrity comes to a proactive manner. Common inspections and tightening of bolts are a very powerful, particularly in high-vibration or high-stress environments. Right kind torque specs will have to all the time be adhered to. The usage of suitable fabrics for the bolts and fasteners is similarly vital. For instance, in a building mission, the use of high-strength metal bolts in important structural connections is a absolute best observe.

That is in particular vital in heavy-duty apparatus, like building equipment.

Figuring out Bolt Tensioning

A a very powerful facet of forestalling bolt loosening lies in working out and meticulously controlling bolt rigidity. Right kind tensioning is not only a technicality; it is a safeguard in opposition to catastrophic failure, a silent promise of reliability, and a testomony to the engineer’s determination to protection and precision. Ignoring the nuances of bolt tensioning can result in pricey upkeep, possible accidents, and a profound sense of unhappiness within the mission’s end result.Exactly controlling the drive implemented to a bolt right through meeting is paramount.

This intricate procedure, ceaselessly overpassed, is the cornerstone of a strong and enduring construction. It isn’t simply about tightening a bolt; it is about organising a predetermined and constant clamping drive that forestalls loosening over the years. This drive, meticulously calibrated, acts as an invisible anchor, making sure the integrity of the relationship.

Significance of Right kind Bolt Pressure

Making sure the right kind preliminary rigidity is significant for long-term efficiency. Inadequate rigidity can result in untimely loosening, leading to a probably unhealthy and dear failure. Conversely, over the top rigidity can result in subject matter fatigue and strain concentrations, probably compromising the relationship’s sturdiness. Keeping up the perfect rigidity guarantees the relationship stays strong beneath various stipulations, combating undesirable motion and making sure the security of all the gadget.

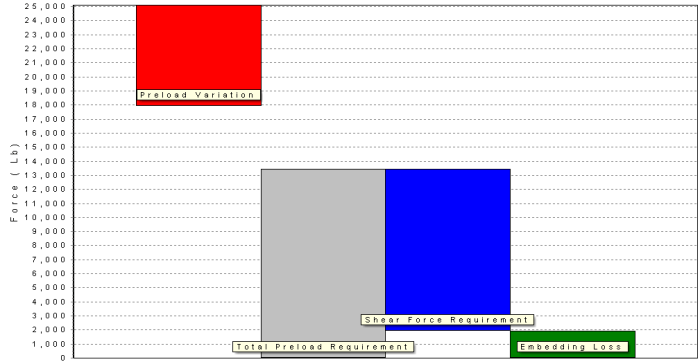

Thought of Preload and its Function

Preload, the preliminary rigidity implemented to a fastener, is a elementary part in combating bolt loosening. This preliminary rigidity creates a clamping drive between the attached portions, resisting the tendency for the bolt to loosen beneath dynamic loading. The preload acts as a buffer, soaking up vibrations and exterior forces, thus keeping up the integrity of the relationship over the years.

This managed clamping drive is the primary defensive line in opposition to undesirable motion and failure.

Strategies for Attaining Proper Bolt Pressure

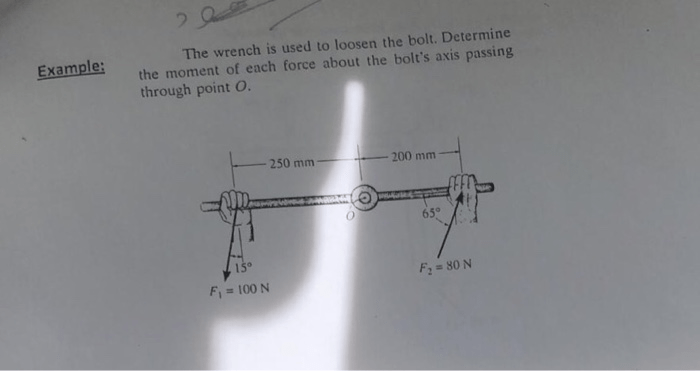

Exact strategies are very important for reaching the right kind bolt rigidity. More than a few gear and methods, designed for accuracy and reliability, be sure that the meant clamping drive is accomplished. Those gear come with torque wrenches, calibrated measuring gear, and in some cases, specialised trying out apparatus. A deep working out of each and every software’s utility is paramount to reaching the specified end result.

Torque Wrenches and Their Programs

Torque wrenches are broadly used gear for controlling the tightening torque implemented to bolts. Those gear supply a right away measure of the implemented rotational drive, making sure that the specified rigidity is accomplished. Various kinds of torque wrenches cater to various packages, providing particular levels and precision ranges. This permits for a adapted option to bolt tensioning, accounting for various fastener sizes and fabrics.

- Torque Wrenches: Torque wrenches measure the torque implemented right through tightening. The torque worth corresponds to a selected clamping drive, making sure constant rigidity throughout fasteners. Other torque wrench varieties be offering quite a lot of levels and precision ranges.

- Calibrated Measuring Gear: Calipers, micrometers, and different calibrated tools supply exact measurements of the bolt’s bodily dimensions. This knowledge is helping resolve the proper torque values required for particular connections.

- Specialised Trying out Apparatus: For advanced or important packages, specialised trying out apparatus could also be hired to measure the true clamping drive accomplished after tightening. This manner supplies an intensive analysis of the effectiveness of the tensioning procedure.

Elements Influencing Bolt Tensioning

A number of components can affect the optimum bolt rigidity. Those components, ceaselessly interconnected, will have to be thought to be for correct calculations and superb implementation. Figuring out those components permits for changes within the tensioning procedure to reach the specified end result.

| Issue | Description | Have an effect on on Tensioning |

|---|---|---|

| Subject matter Homes | The tensile energy, elasticity, and yield energy of the bolt and attached fabrics at once affect the desired rigidity. | Other fabrics require other tensioning methods. |

| Temperature | Temperature fluctuations can impact the fabric homes of the elements, influencing the clamping drive. | Changes will have to be made to atone for temperature adjustments. |

| Load Cycles | Repeated loading and unloading cycles can result in fatigue and loosening over the years. | Upper load cycles ceaselessly necessitate upper preliminary preload values. |

| Bolt Measurement and Thread Kind | The scale of the bolt and thread kind dictate the proper tightening torque. | Smaller bolts require smaller torque settings. |

Strategies for Fighting Loosening

The relentless dance of tightening and loosening, of forces vying for dominance, can go away bolts prone. We will have to perceive the insidious nature of loosening, how reputedly minor vibrations, thermal fluctuations, or repeated stresses can slowly get to the bottom of the bonds that cling our buildings in combination. Fighting this disaster calls for a deep working out of the mechanisms at play, and a dedication to using the proper gear and methods.

Lock Washers: A Defend Towards Slippage

Lock washers are inventive little units that become a easy washing machine into a formidable preventative measure in opposition to loosening. They invent friction and mechanical interlocking, appearing as a barrier in opposition to the weather that may in a different way result in loosening. They arrive in quite a lot of sizes and styles, each and every adapted to express packages. The correct variety and set up of lock washers are a very powerful for luck.

- Spring Lock Washers: Those washers characteristic a spring-like design that creates a gripping drive in opposition to the bolt head or nut, combating slippage. The inherent spring motion of the washing machine creates a competent clamping motion. Those are in particular superb in scenarios the place vibration is a significant component. A not unusual utility comes to attaching elements to equipment liable to consistent motion, reminiscent of conveyor programs.

- Flat Lock Washers: Those washers make use of a easy, flat design that, when accurately put in, guarantees the nut does no longer back down. They’re identified for his or her huge applicability, discovering use in plenty of fastening packages. A key benefit is their rather low charge in comparison to different varieties of lock washers.

- Teeth Lock Washers: Those washers use a chain of tooth or projections to chunk into the mating floor, thus combating rotation and loosening. This tooth design creates a vital frictional drive, making them exceptionally well-suited for scenarios involving excessive strain and vibration. They’re ceaselessly utilized in automobile and commercial settings the place consistent stress or motion is provide. Believe the use of them when the bolt wishes to resist repeated heavy affects or excessive vibration ranges.

Nylock Nuts: A Revolution in Fastening Safety

Nylock nuts, a contemporary wonder in fastening era, are designed to withstand loosening. Their distinctive inner tooth or ridges create a self-locking mechanism. They supply awesome retaining energy in comparison to conventional nuts, getting rid of the will for extra locking units in lots of instances.

Cotter Pins: Easy, But Efficient

Cotter pins are easy but superb mechanical units used to stop loosening. They supply a protected, certain prevent that forestalls the loosening of a bolt or different fastener. The design is easy; the pin is inserted thru a slot within the fastener and bent to fasten it in position. This system gives a strong, cost-effective answer, and it’s in particular appropriate for scenarios the place excessive a lot are provide, reminiscent of equipment elements.

Those are ceaselessly used when a extra really extensive locking mechanism is wanted.

A Comparative Information to Fasteners and Preventive Measures

| Fastener Kind | Suitable Preventive Measures |

|---|---|

| Bolts with excessive vibration publicity | Spring lock washers, nylock nuts, or a mix of each. |

| Bolts topic to common thermal biking | Flat lock washers or cotter pins, relying at the utility and cargo necessities. |

| Bolts beneath vital tensile strain | Teeth lock washers, cotter pins, or specialised high-strength lock washers. |

| Bolts in packages the place aesthetics are important | Flat lock washers, nylock nuts, or different low-profile choices. |

Right kind Set up: Making sure Lasting Safety

Right kind set up is paramount to the effectiveness of any preventative measure. Moderately apply the producer’s directions for each and every particular locking tool. Unsuitable set up can compromise the locking mechanism, rendering it useless. All the time make certain the locking mechanism is securely engaged, and take a look at for correct seating to stop slippage.

Environmental Elements Affecting Bolt Safety

The relentless march of time and the unforgiving nature of our surroundings ceaselessly conspire to undermine the very foundations of our engineered buildings. Bolts, the unsung heroes retaining the whole thing in combination, are in particular liable to the insidious results in their atmosphere. Figuring out those environmental pressures is a very powerful to making sure the longevity and reliability of bolted connections, safeguarding in opposition to catastrophic screw ups and dear upkeep.Environmental forces, like relentless vibration, the unpredictable swings of temperature, and the corrosive include of moisture, can all compromise the integrity of a bolt’s grip.

Those components, ceaselessly running in tandem, can slowly however indisputably weaken the bond between the fastener and the fabric, resulting in loosening and in the long run, failure. Spotting those insidious forces and working out their mechanisms is paramount in designing and keeping up powerful, dependable programs.

Figuring out Environmental Hazards

Environmental components play a important position within the safety of bolted connections. Elements reminiscent of vibration, temperature fluctuations, and corrosion considerably affect the longevity and reliability of bolted joints. The interaction between those components and the fabric homes of the bolt and the attached portions will have to be thought to be to make sure long-term efficiency.

Mechanisms of Bolt Loosening Because of Environmental Elements

Vibration, a relentless presence in lots of commercial and mechanical packages, can induce cyclical stresses at the bolt, resulting in fatigue and loosening over the years. Temperature fluctuations purpose thermal growth and contraction of the attached portions, inducing strain and probably exceeding the retaining capability of the bolt. Corrosion, ceaselessly insidious and invisible, weakens the fabric of the bolt and the encircling surfaces, lowering the clamping drive and resulting in loosening.

Have an effect on of Other Environments on Bolt Subject matter and Fastener Integrity

The severity of environmental results varies significantly relying at the particular atmosphere. Outside buildings, subjected to the relentless cycle of freezing and thawing, face a relentless combat in opposition to growth and contraction. The presence of salt spray in marine environments speeds up corrosion, dramatically decreasing the lifespan of bolted connections. In humid environments, moisture and condensation can give a contribution to corrosion and weaken the fastener’s integrity.

Examples of Environmental Have an effect on on Bolt Connection Longevity, The right way to calculate {that a} bolt may not come unfastened

A bridge deck, uncovered to consistent temperature adjustments and vibration from site visitors, calls for bolts designed to resist those forces. Failure to account for those stresses can result in the loosening of bolts, jeopardizing the structural integrity of the bridge. In a similar way, in marine packages, bolts will have to be immune to corrosion, as salt spray considerably speeds up rust formation. Right kind collection of corrosion-resistant fabrics and coatings is significant for the long-term reliability of bolted connections in those environments.

Comparative Research of Environmental Results on Bolt Sorts

| Environmental Situation | Vibration | Temperature Fluctuation | Corrosion |

|---|---|---|---|

| Outside Buildings (Metal Bolts) | Prime | Average to Prime | Average |

| Marine Environments (Stainless Metal Bolts) | Average | Average | Prime |

| Commercial Equipment (Prime-Power Bolts) | Prime | Average | Average to Low (relying on atmosphere) |

This desk highlights the various affect of environmental stipulations on other bolt varieties. The severity of each and every issue can considerably impact the selection of subject matter and design for the bolted connection, emphasizing the significance of cautious attention in various packages.

Design Concerns for Fighting Loosening

The very middle of protected fastening lies no longer simply within the tightening procedure, however within the meticulous design that anticipates and mitigates possible loosening. A poorly conceived design, regardless of how meticulously tightened, can result in catastrophic failure, with penalties starting from minor inconvenience to probably life-threatening scenarios. A considerate design manner is a very powerful in combating those screw ups, making sure the longevity and reliability of the mounted meeting.A well-designed fastener gadget anticipates the forces and stresses it’s going to stumble upon all over its lifespan.

This proactive manner, incorporating a deep working out of subject matter homes, environmental influences, and possible stresses, ends up in a gadget engineered to resist the trials of provider and handle its integrity over the years. This preventative design considering is very important for construction accept as true with and self assurance within the product’s efficiency.

Bolt Variety

Right kind bolt variety is paramount. Selecting the proper bolt subject matter, measurement, thread kind, and head taste is significant to combating loosening. A bolt this is too vulnerable to resist the implemented a lot will inevitably fail, whilst one this is overly powerful could be unnecessarily pricey. The right kind selection considers the precise utility, together with the predicted load, atmosphere, and anticipated lifespan.

A bolt designed for a high-stress utility in a corrosive atmosphere will fluctuate considerably from a bolt utilized in a low-stress, dry surroundings. A radical working out of the applying is essential.

Design Parameters

A number of design parameters give a contribution to combating loosening. Those come with taking into account the kind of load, the anticipated provider lifestyles, and the environmental stipulations. The design will have to account for components like vibration, thermal growth, and cyclic loading. An in depth research of those parameters is very important for creating a strong design that may face up to the demanding situations of the actual international.

- Load Distribution: Uniform load distribution around the fastener is significant. Concentrated a lot may cause localized strain and possible loosening. The design will have to distribute the burden flippantly to stop localized failure.

- Preload Calculation: Exact calculation of the desired preload is a very powerful. Underneath-preloading can result in slippage, whilst over-preloading can injury the elements.

Cautious calculation, in line with the burden traits, is essential.

- Thread Engagement Duration: Enough thread engagement period is necessary. A shorter engagement period reduces the resistance to loosening, expanding the danger of failure. The period of thread engagement will have to be enough to resist the implemented a lot.

- Corrosion Resistance: In environments at risk of corrosion, corrosion-resistant fabrics will have to be selected.

Corrosion can weaken the fastener and compromise its talent to handle rigidity.

Subject matter Variety

Subject matter variety is a key part within the design procedure. The selected subject matter will have to possess enough energy, ductility, and corrosion resistance to resist the anticipated stresses and environmental stipulations. Other fabrics reply otherwise to quite a lot of stresses and environmental components.

- Prime-Power Bolts: In challenging packages, high-strength bolts are ceaselessly essential to handle excessive rigidity and save you loosening. Those bolts supply a better resistance to loosening in comparison to usual bolts.

- Corrosion-Resistant Alloys: In corrosive environments, stainless-steel or different corrosion-resistant alloys are most well-liked to stop untimely failure because of corrosion. This selection guarantees the long-term integrity of the fastening.

- Ductility Concerns: Fabrics with good enough ductility can take in one of the crucial power from affects or vibrations, combating unexpected failure. This option is vital in packages with fluctuating stresses.

Design Instance: Prime-Power Vessel

Believe a high-pressure vessel, a very powerful in chemical processing or energy technology. The design accommodates high-strength bolts with a protracted thread engagement period, sparsely calculated preload to resist the interior stress. The bolts are product of a corrosion-resistant alloy to stop untimely failure because of chemical publicity. The vessel’s design contains options to mitigate thermal growth and vibration.

The collection of those elements guarantees the long-term reliability and protection of the vessel.

Design Patterns for Lengthy-Time period Safety

A number of design patterns advertise long-term bolt safety. Those come with using locking units, tensioning strategies that account for vibration and temperature fluctuations, and design issues that accommodate long term upkeep wishes. Those proactive measures make certain the meeting’s persevered efficiency.

- Locking Units: Use of locking washers, cotter pins, or different locking units to stop loosening because of vibration or cyclic loading. This can be a a very powerful preventative measure.

- Anti-Rotation Options: Put in force options to stop rotation of the attached portions, combating the bolt from loosening beneath load.

- Common Inspection and Repairs: Design the gadget with periodic inspection and upkeep issues in thoughts.

This proactive manner is helping be sure that the fastener gadget stays protected.

Troubleshooting Free Bolts

A nagging, continual feeling of unease creeps in when a bolted connection feels much less protected. It is a refined tremor, a whisper of doubt concerning the integrity of the construction, the possibility of catastrophic failure. Ignoring those caution indicators can result in disastrous penalties, from minor inconvenience to finish gadget failure. This segment will meticulously dissect the indications of loosening bolts, providing sensible how you can diagnose the problem and repair the relationship’s unwavering energy.

Commonplace Signs of Free Bolts

Free bolts are ceaselessly refined villains, hiding their treachery in the back of reputedly customary appearances. Figuring out the telltale indicators is a very powerful to combating vital injury. Those signs range relying at the utility and the surroundings, however some basic patterns emerge. A visible inspection is ceaselessly step one, adopted via extra in-depth diagnostics.

Strategies for Diagnosing and Assessing Bolt Loosening

Figuring out the level of loosening calls for cautious statement and tactile analysis. Tactile strategies, like making use of delicate stress to the attached elements, can ceaselessly disclose slight motion or play. The usage of a torque wrench to measure the present tightening drive is a a very powerful step. Evaluating the present studying to the unique torque worth finds if the bolt has loosened.

If the variation is essential, re-tensioning or substitute could be essential. Acoustic research, whilst much less not unusual, can hit upon refined adjustments within the sound emitted via the relationship, indicating possible loosening.

Re-tensioning or Changing a Free Bolt

Re-tensioning a unfastened bolt is a important process, requiring meticulous consideration to element. First, the relationship will have to be inspected to make sure no hidden injury exists. Then, the proper torque wrench is used to use the proper tightening drive, following the producer’s specs. If the bolt is excessively unfastened or broken, substitute is ceaselessly the extra prudent manner.

On this case, a brand new bolt with the right kind specs is put in the use of the correct tightening process.

Examining Current Connections to Determine Doable Problems

Common inspection of present bolted connections is necessary for proactive upkeep. Visually investigate cross-check for any indicators of wear and tear or deformation at the bolt head or the relationship issues. Observe any corrosion or injury at the connecting surfaces, as those components can give a contribution to loosening. Checking the encircling house for strain concentrations or issues of possible affect can lend a hand save you long term loosening.

Visible inspection will have to be accompanied via tactile analysis to substantiate the perceived looseness.

Desk of Commonplace Signs of Free Bolts in More than a few Programs

| Utility | Commonplace Signs |

|---|---|

| Equipment | Vibrating or damn noises, lowered efficiency, slow shifts in alignment |

| Building | Sagging or tilting buildings, noticeable gaps between attached parts, cracking or stressing of the supporting construction |

| Automobiles | Asymmetric tire put on, extraordinary noises (e.g., squeaking or groaning), vibrations |

| Piping Techniques | Leakages, extraordinary vibrations or pulsations, misalignment of pipe sections |

Repairs Methods for Bolt Safety

A a very powerful facet of making sure the longevity and protection of any engineered construction is the constant upkeep of its bolted connections. Neglecting those reputedly small main points can result in catastrophic screw ups, costing no longer simply cash however probably endangering lives. Right kind upkeep methods, subsequently, are paramount in mitigating those dangers and making sure the structural integrity of important elements for years yet to come.

A proactive manner, emphasizing common inspections and preventative measures, is the cornerstone of long-term bolt safety.

Preventative Repairs Procedures

A well-defined preventative upkeep program is necessary for the sustained reliability of bolted connections. This program will have to surround a chain of steps that meticulously investigate cross-check and handle the integrity of each and every fastener. Those procedures will have to be adapted to the precise utility and environmental stipulations, making sure the effectiveness and potency of the upkeep technique.

- Visible Inspection: A regimen visible inspection is the primary defensive line. Moderately read about the bolts for any indicators of wear and tear, reminiscent of deformation, corrosion, or over the top put on. A willing eye can hit upon refined signs of possible issues ahead of they escalate to primary problems. Visible inspection will have to quilt all the fastener, together with the top, threads, and the encircling spaces.

- Torque Verification: Torque verification is a important element of preventative upkeep. Continuously take a look at the torque values on important fasteners. This process will have to be carried out the use of calibrated torque wrenches, making sure correct readings. Variations from the unique torque specs will have to be famous and addressed promptly. This is helping to spot any adjustments within the tightening traits of the fasteners and permits for the essential changes to be made.

- Corrosion Tracking: Environmental components considerably affect bolt safety. Corrosion is a vital worry that may weaken the integrity of fasteners over the years. Continuously investigate cross-check bolts for indicators of corrosion, the use of suitable inspection gear and methods. Broaden a technique for shielding bolts from corrosion, reminiscent of making use of protecting coatings or using correct garage procedures. This proactive manner will safeguard the long-term safety of bolted connections.

- Lubrication: Right kind lubrication is significant to stop friction and put on. Common lubrication of threads and mating surfaces guarantees clean operation and prolongs the lifetime of the bolted connections. Right kind lubrication will have to be carried out following the producer’s specs.

Structured Method to Examining and Tightening Bolts

A structured option to analyzing and tightening bolts guarantees consistency and accuracy. This systematic procedure will have to be documented and adopted meticulously for each inspection.

- Identify a Agenda: A typical agenda for inspections and tightening is a very powerful. This agenda will have to be in line with the criticality of the applying, the environmental stipulations, and the historical past of the bolted connections. The frequency will have to be adjusted as had to deal with possible problems ahead of they turn into vital.

- Use Standardized Procedures: Broaden standardized procedures for analyzing and tightening bolts. Those procedures will have to come with detailed steps, essential gear, and appropriate tolerances. This manner guarantees consistency and accuracy within the inspection procedure.

- Make use of Educated Team of workers: Educate workforce on the correct ways for analyzing and tightening bolts. Supply complete coaching that covers the precise procedures, the significance of accuracy, and the prospective penalties of errors. Certified and educated workforce will carry out the inspections as it should be and reliably.

- Monitor Efficiency Information: Totally report the inspection effects. File any discrepancies or extraordinary findings. Monitoring the efficiency information over the years will supply insights into possible developments or problems.

Significance of Documentation

Complete documentation is paramount in keeping up bolt safety. Detailed information of all upkeep actions, together with dates, instances, findings, and movements taken, are very important for responsibility, traceability, and ancient research.

- Monitoring Repairs Historical past: Handle an entire and correct document of all upkeep actions, together with the date, time, workforce concerned, and the result of each and every inspection. This historical past can lend a hand are expecting possible issues and facilitate proactive upkeep methods.

- Auditing and Research: Keeping up detailed information permits for superb audits and research of the upkeep procedures. Those information supply a transparent image of the entire situation of the bolted connections and make allowance for knowledgeable choices relating to long term upkeep methods.

Repairs Checklists

Pre-designed checklists supply a structured option to inspections and upkeep. Those checklists, adapted to express packages, make certain consistency and completeness within the upkeep procedure. In addition they function precious gear for coaching and reference.

| Utility | Key Inspection Issues |

|---|---|

| Plane Touchdown Equipment | Wheel alignment, tire stress, brake operation, strut situation, attachment issues, bolt torque. |

| Bridges | Growth joints, fortify buildings, anchor bolts, deck integrity, fastener situation, and torque values. |

| Building Equipment | Engine mounts, hydraulic strains, and significant connections. |

Ultimate Ideas: How To Calculate That A Bolt Would possibly not Come Free

In conclusion, making sure bolt safety comes to a multifaceted manner. Cautious attention of tensioning strategies, preventive measures, and environmental components are very important for long-term reliability. By means of working out those parts, you’ll be able to design and handle protected connections that face up to loosening. Take note, a well-maintained connection is a secure and dependable connection.

Fast FAQs

What are the average signs of a unfastened bolt?

Visual motion of the bolt head, extraordinary noises right through operation, or a sense of looseness when touching the relationship are not unusual signs. A unfastened bolt may also be accompanied via a transformation within the tightness really feel. Those are ceaselessly the primary indicators of an issue.

How do temperature fluctuations impact bolt safety?

Temperature adjustments purpose subject matter growth and contraction. This can result in loosening of bolts, particularly in environments with vital temperature swings. Thermal strain can weaken the relationship over the years.

What is the distinction between a torque wrench and a calibrated measuring software?

Torque wrenches measure the rotational drive implemented to the bolt, whilst calibrated measuring gear at once measure the bolt rigidity. Torque wrenches are extra not unusual for on a regular basis use, whilst calibrated gear are ceaselessly utilized in extra important packages requiring exact tensioning.

How can I resolve the proper bolt kind for a selected utility?

Selecting the proper bolt kind is determined by components like the fabric, load necessities, environmental stipulations, and the specified degree of safety. Believe the fabric’s energy, possible vibrations, and environmental components when selecting the best fastener.